News

-

Tungsten carbide burn back

Back-burning refers to the re-sintering method for bending deformed products, infiltrated, decarburized products and tungsten carbide products with excessive pores. (1) Backburning of infiltrated and decarburized products. Carburizing and back-burning usually use high-temperature calcined...Read more -

Defect analysis of cemented carbide compacts

Most defects in the precision and apparent quality of cemented carbide blanks occur during the pressing production process. Effectively controlling the occurrence of pressing defects is the key to ensuring the precision and apparent quality of cemented carbide blanks. With the development of prec...Read more -

Molding and Quality Control

Cemented carbide molding is to compact the mixed powder to obtain the required density and density uniformity, and the required shape. The process of producing compact shapes and dimensional accuracy requires that the compacted compact must have a certain strength. The relative density of the com...Read more -

Application of CIM in cemented carbide manufacturing

CIM is an organization in the information age, a philosophy for managing enterprise production, and a production model for new enterprises in the information age. The specific implementation based on this philosophy and technology is the Computer Integrated Manufacturing System, or CIMS. Well-kno...Read more -

Recycling and Utilization of Carbide

At present, there are several main categories of recycling processes for tungsten carbide.One is the so-called high-temperature treatment method, which includes: saltpeter melting method, air oxidation sintering method, oxygen calcination method, etc.; the other is mechanical crushing method, whi...Read more -

Effect of W content in the tungsten carbide crystal bonding phase on the flexural strength of the alloy

Bending strength is a very important physical property of cemented carbide. For high-cobalt alloys, its strength increases with the increase of W content; while for low-cobalt alloys, the opposite is true. This is because after the cobalt phase of the high-cobalt alloy is solid-solution strengthe...Read more -

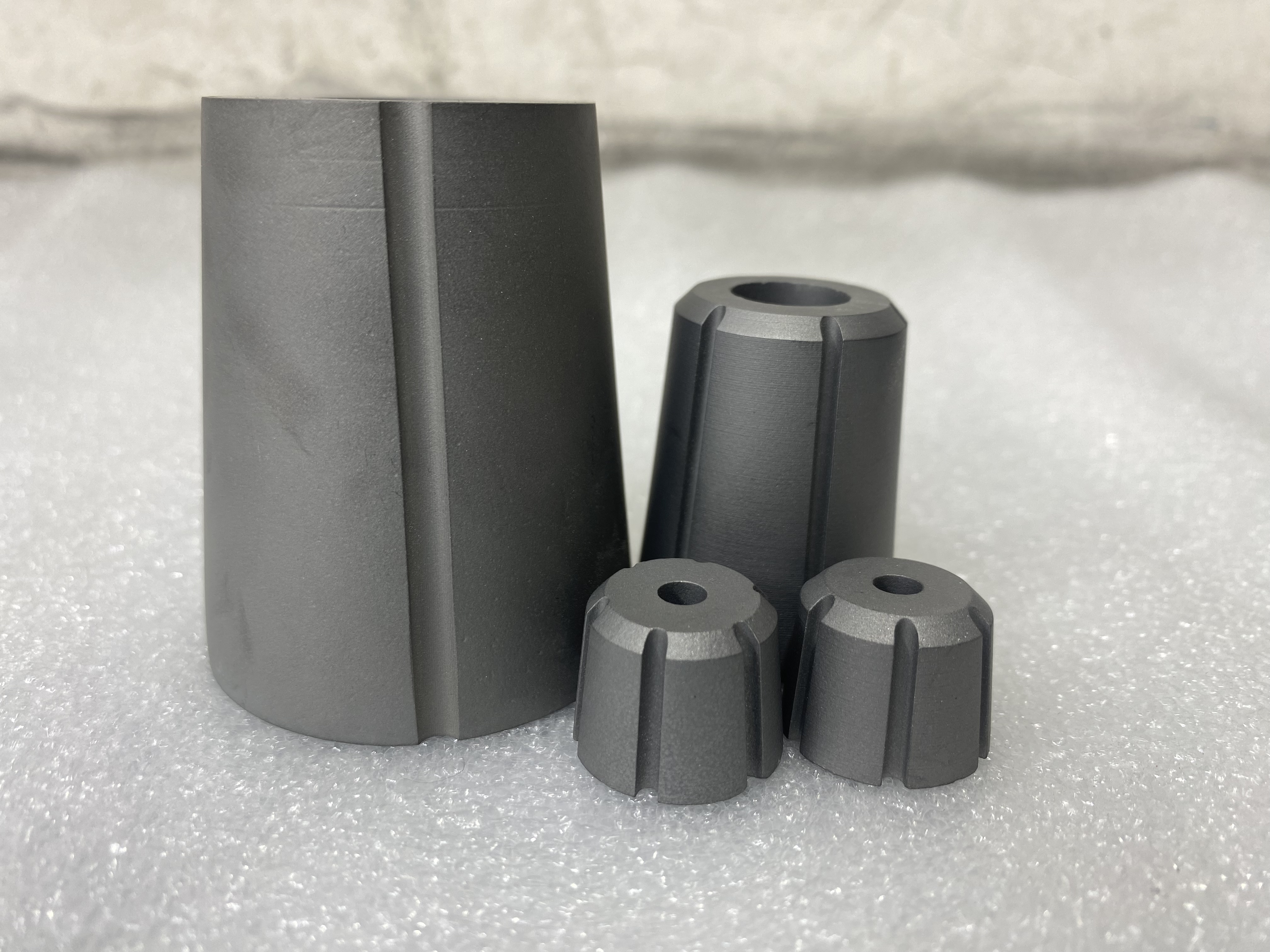

Carbide precision molding process

The ordinary pressing production process of cemented carbide is relatively simple. It only determines the pressing unit weight and pressing size of a certain model through pressure testing, and uses this as the production process parameters to implement it throughout. There are no clear requireme...Read more -

Submicron and ultrafine carbide

The submicron and ultrafine cemented carbide currently put into commercial production mainly consists of submicron and ultrafine WC, Co powder and appropriate grain length. It is prepared from large inhibitors (mainly Cr3C2, VC), and its grain size is 0.2~0.8μm. Due to the unique properties of s...Read more -

Cemented Carbide Products Tungsten Powder Preparation

Ultra-fine particle tungsten powder is black, fine particle tungsten powder is dark gray, and coarse particle tungsten powder is light gray with metallic luster. Metal tungsten powder can be produced by reducing tungsten oxide. The main reduction methods are hydrogen reduction and carbon reductio...Read more -

Carbide and cermet preparation

WC-Co hard alloys have good microwave adaptability. During the sintering process, the loss modes that work in the low temperature zone are mainly polarization relaxation loss and magnetic loss, while in the high temperature zone the alloy absorbs microwave energy. Mainly in the form of dielectric...Read more -

How hard is it to break tungsten carbide?

Cemented carbide is a composite material produced by powder metallurgy from a refractory metal hard compound and a bonding metal or alloy; it is a cermet. Refractory metal hard compounds usually refer to carbides, nitrides, borides and silicides of transition elements (tungsten, titanium, vanadiu...Read more -

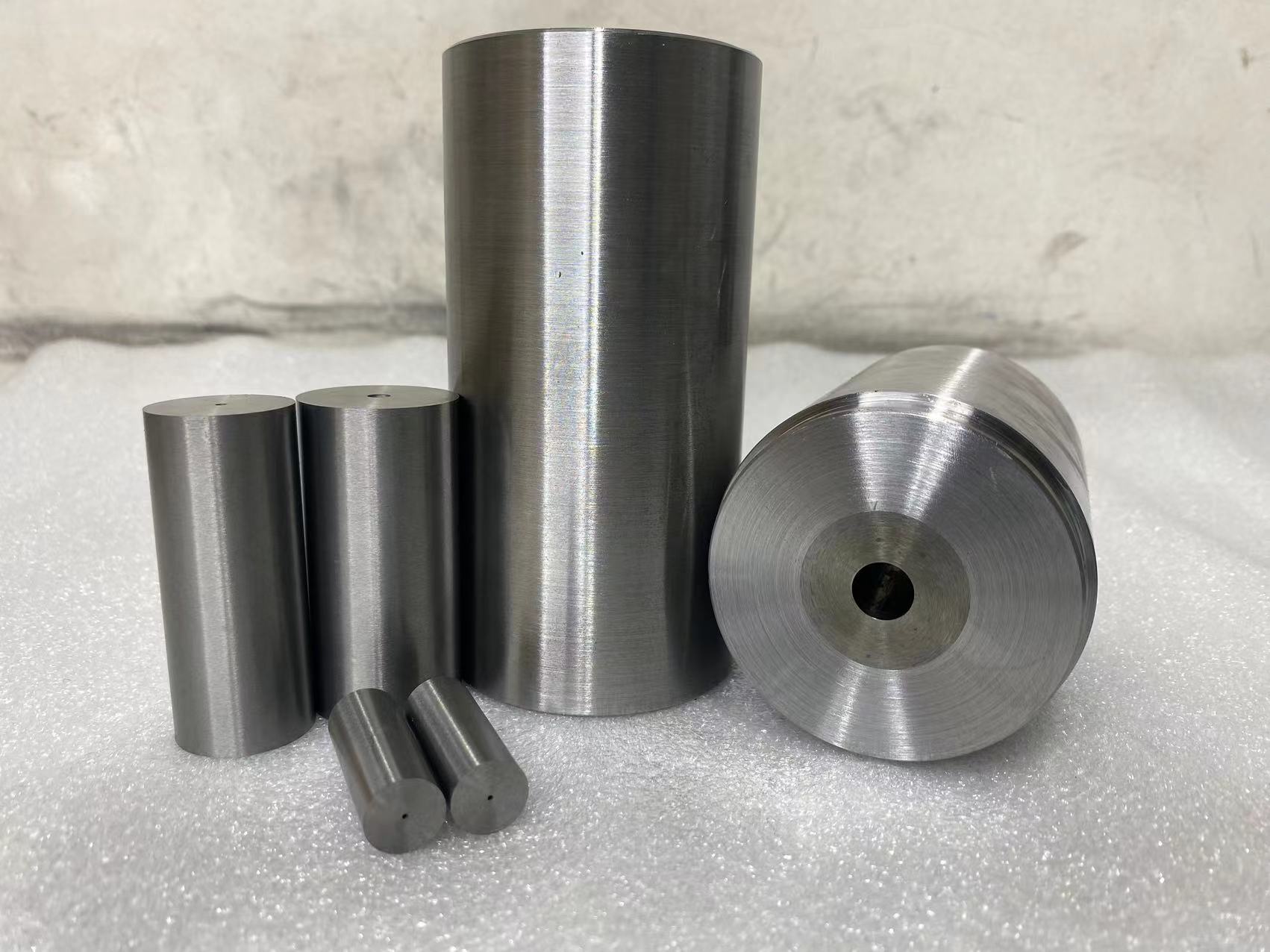

What are tungsten carbide dies for?

Commercially, they are usually divided into: cutting blades, mining alloys, and wear-resistant alloys according to the use of the products. The classification and uses of cemented carbide are not very standardized in relevant domestic books, magazines, and materials. They are usually classified a...Read more