WC-Co hard alloys have good microwave adaptability. During the sintering process, the loss modes that work in the low temperature zone are mainly polarization relaxation loss and magnetic loss, while in the high temperature zone the alloy absorbs microwave energy. Mainly in the form of dielectric loss and conductivity loss.

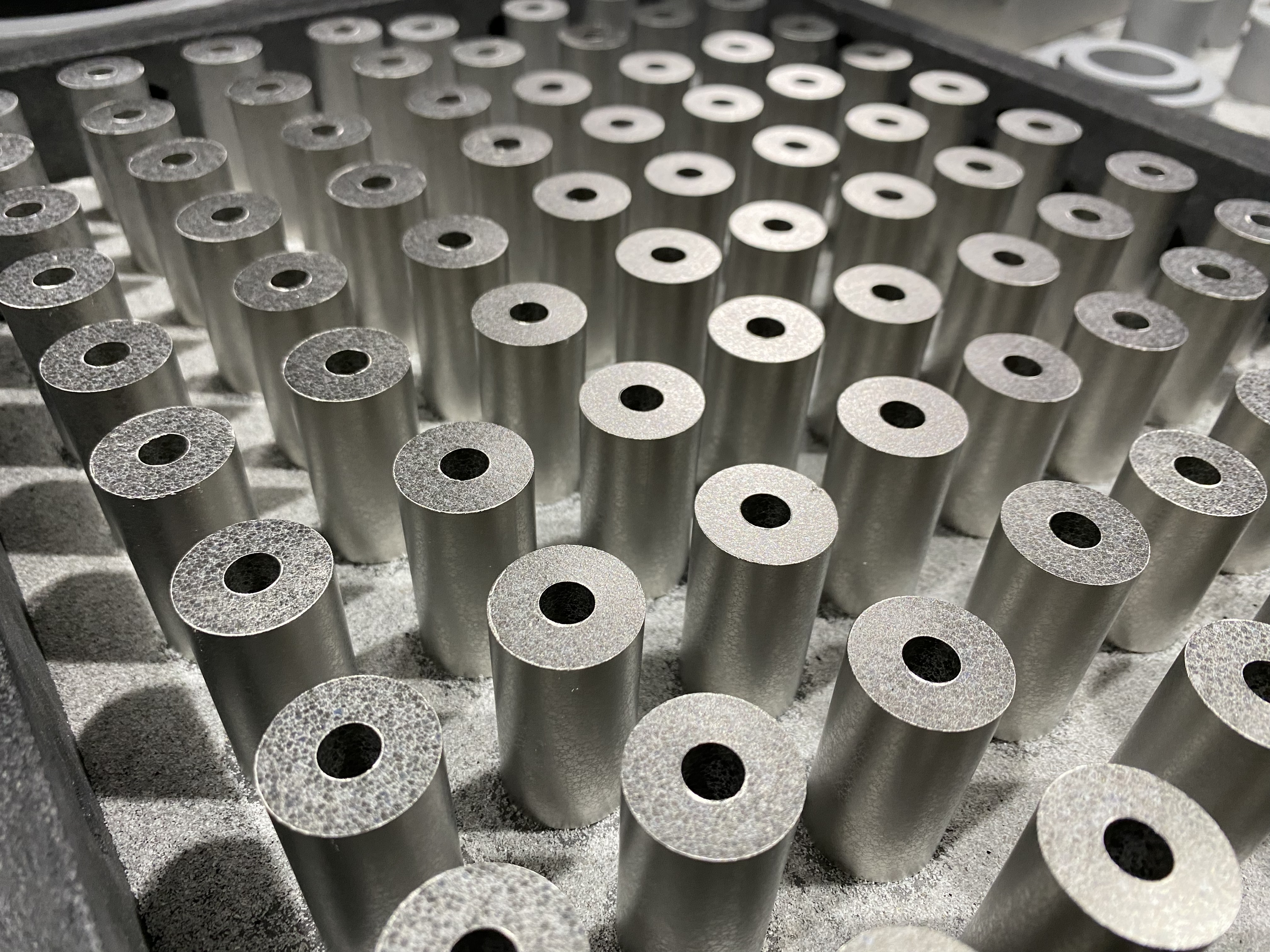

The alloy with the addition of 0.4% VC and 0.2% Cr3C2 (mass fraction) as auxiliary materials has the best performance; the use of vacuum microwave sintering significantly improves the performance of the alloy. Using multi-cavity microwave sintering WC-8Co, it is sintered at 1400°C without heat preservation. The density can reach 14.71g/cm, the HRA reaches 90.3, and the structure is uniform.

Microwave sintering technology can be used to prepare ultra-fine cermets with fine grains, uniform structure and excellent performance. As the sintering temperature increases, the shrinkage, density, flexural strength and hardness of ultra-fine cermets first increase and then decrease, with a maximum value appearing at 1500°C; suitable microwave sintering process for ultra-fine cermets After being kept at 1500°C for 30 minutes, the flexural strength and hardness values are 1547MPa and 90.6HRA respectively, which are increased by 24.0% and 0.7% respectively compared with conventional sintering.

Post time: Jan-03-2024