Back-burning refers to the re-sintering method for bending deformed products, infiltrated, decarburized products and tungsten carbide products with excessive pores. (1) Backburning of infiltrated and decarburized products. Carburizing and back-burning usually use high-temperature calcined graphite particles or a mixture of graphite particles and Al2O3 powder as the medium, and carry out back-burning under hydrogen protection.

Decarburization and backburning usually use Al203 powder calcined at high temperature or a mixture of Al203 powder and fine W powder as the medium, and backburning is performed under hydrogen protection.

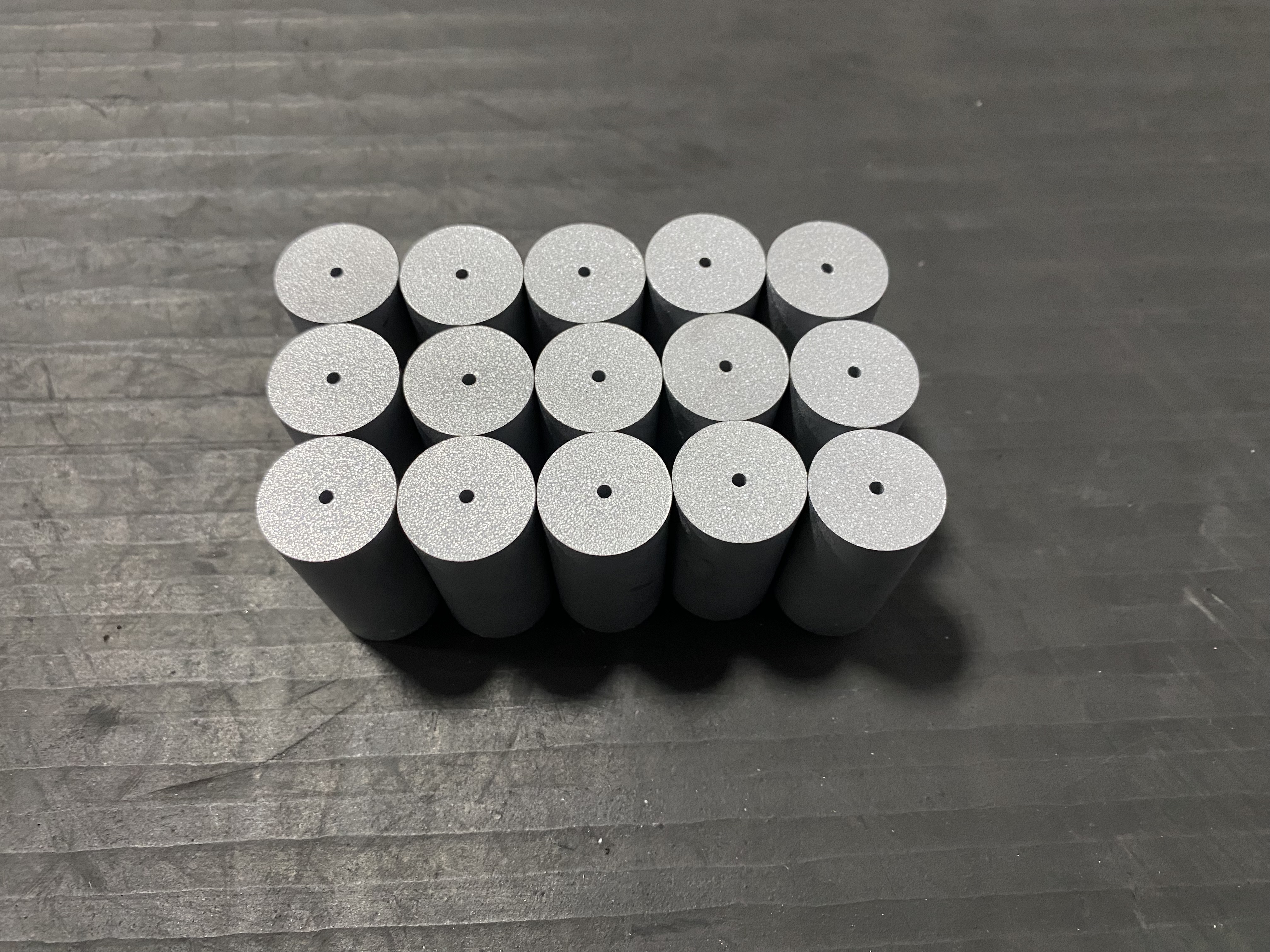

(2) The porosity exceeds the standard and burns back. If the porosity of tungsten carbide sintered products (pores not larger than 25 μm) exceeds the standard, a pressure sintering furnace can be used for pressure sintering at a pressure of about 10MPa. The sintering temperature should be about 20°C lower than the initial sintering temperature of the product. Processing at higher pressures using hot isostatic pressing is more effective.

(3) Straightening. Backburning is carried out by applying pressure and using hydrogen protection or vacuum state at a temperature slightly higher than the eutectic temperature. The pressurizing weight can be adjusted or the correction temperature can be increased according to the correction condition of the product, but the correction temperature should not be higher than the initial sintering temperature of the product.

Post time: Jan-07-2024