News

-

Start work to ensure the normal operation of all departments and ensure that orders are delivered as scheduled

Start work to ensure the normal operation of all departments and ensure that orders are delivered as scheduled The peak construction season means an increase in workload, so more resources and personnel need to be prepared to meet market demand. Stable tungsten carbide quality and delivery effici...Read more -

Take multiple measures to achieve smooth start of construction

The plan for the year begins in spring. Get off to a good start and get on the fast track quickly. Summarize accurately and have clear goals! All employees of Hengrui Cemented Carbide Co., Ltd. read with heart, understand with emotion, and practice with pragmatism. Hengrui Company will definitely...Read more -

The difference between carbide strips and tungsten steel strips

The colors of carbide strips and tungsten steel strips are different The color of cemented carbide strips is usually lighter than that of tungsten steel strips, and the colors are mainly gray, silver, gold, and black. This is because the carbide strip contains more metal elements, which makes it ...Read more -

Effect of cobalt content in cemented carbide on material properties

The cobalt content of cemented carbide has a significant impact on the properties of the material, including hardness, toughness, wear resistance and impact resistance. The following is the relationship between the cobalt content of cemented carbide and its performance 1.Hardness Cemented carbid...Read more -

The impact of cemented carbide carbon content control on quality

The carbon content in cemented carbide was studied using the vacuum sintering method. The analysis pointed out that the total carbon content in the raw materials plays a decisive role in the carbon content of the alloy. In addition, the hard particles in the pressed powder are formed during the p...Read more -

Storage and maintenance of carbide molds

Mold Storage Carbide molds have the characteristics of high hardness and high wear resistance, but they are also highly brittle and are easily damaged by external impacts, extrusions, etc. Therefore, when storing molds, care should be taken to avoid being affected by external physical and chemica...Read more -

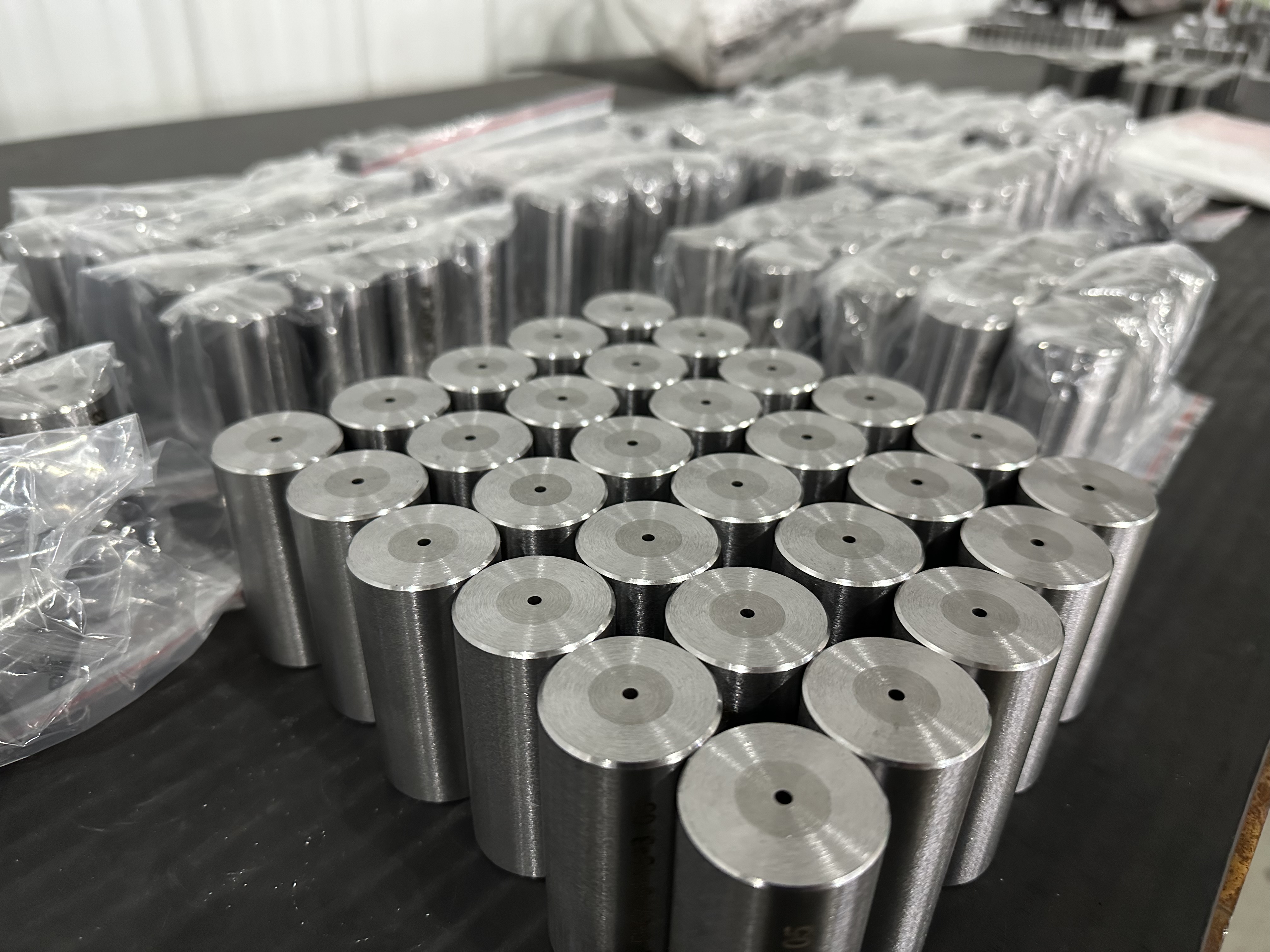

Mold manufacturing installation and commissioning

The manufacturing of cemented carbide molds needs to be based on specific standards and processes, including material selection, processing technology, heat treatment technology, precision grinding and other aspects. Scientific and standardized manufacturing standards must be followed during the ...Read more -

Mold classification

Classified by mold structure form, such as single-process molds, compound punching dies, etc.; Classified by use objects, such as automobile covering parts, motor molds, etc.; Classified by the properties of processed materials, such as molds for metal products, molds for non-metallic products, e...Read more -

The impact of stainless steel stamping tungsten carbide molds on product quality

In the stainless steel stamping process, tungsten carbide mold is a very important component. The choice of mold directly affects the quality, cost and production efficiency of stamping parts. Therefore, when selecting mold materials, you need to consider all factors to find the best choice. Fir...Read more -

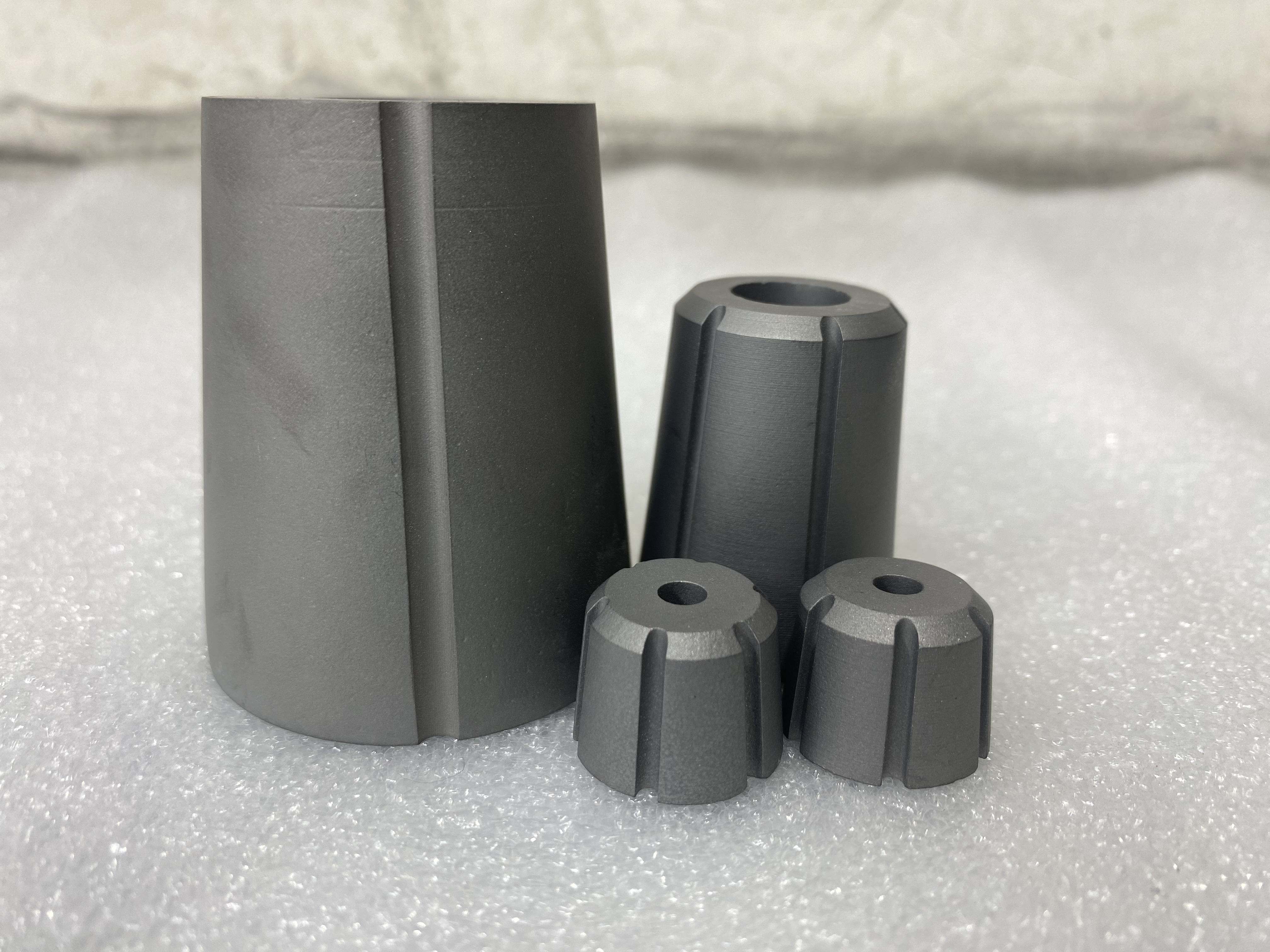

Our Tungsten Carbide Advantage

Our Tungsten Carbide Advantages 1. Tungsten carbide uses cold pressing and vacuum sintering processes to produce cemented carbide non-standard special-shaped alloys. The product performance is stable and the quality is reliable. 2. Unique production control and detection technology controls the i...Read more -

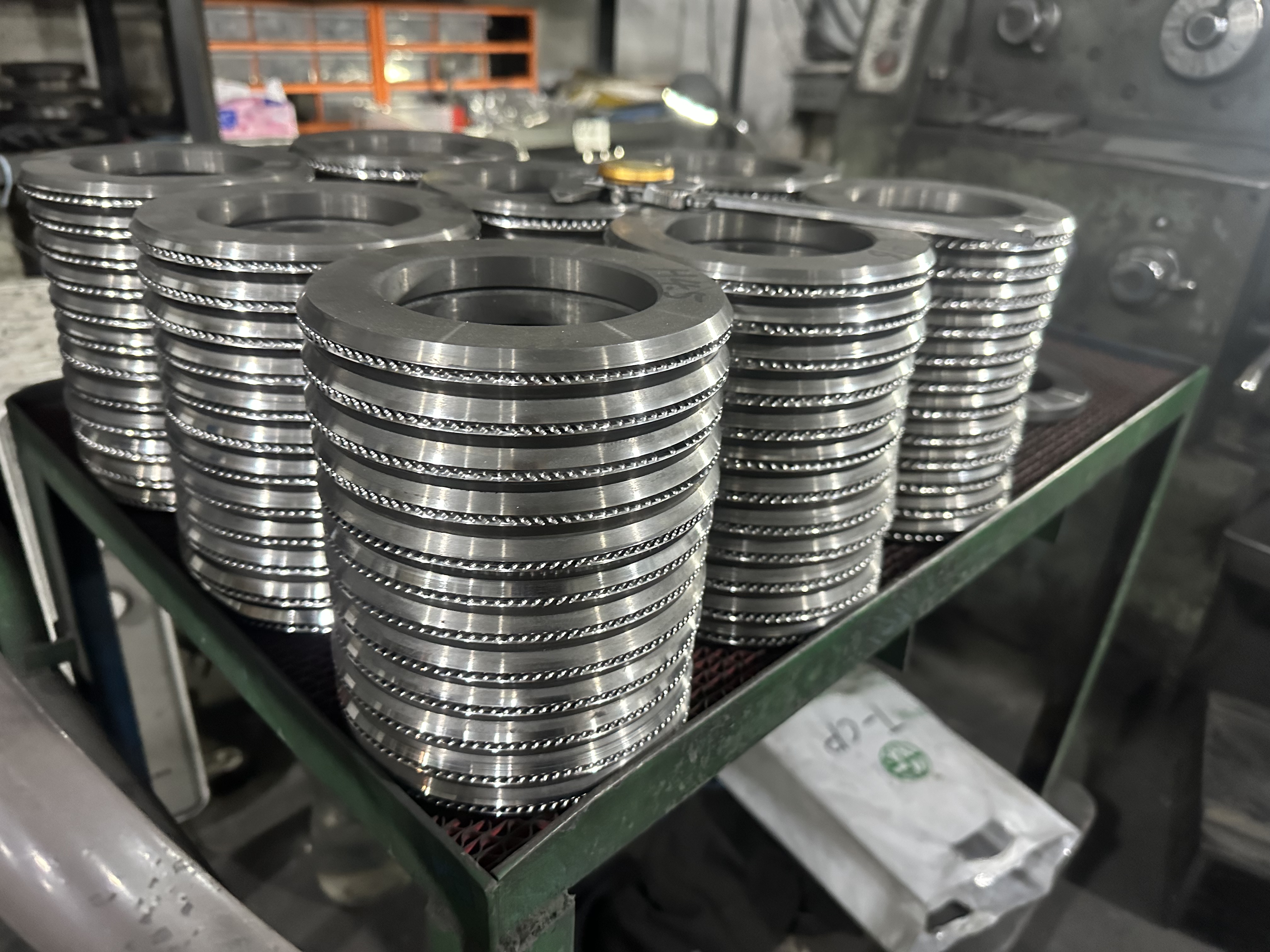

Carbide roller rings

Carbide roller rings (also called tungsten carbide roller rings) have superior performance, stable quality, high product processing precision, good wear resistance and high impact resistance. Alloy rollers are available in two types: integral type and combined type. . Carbide rolls have high hard...Read more -

Professional manufacturer of cemented carbide rollers

Our company’s 36XΦ80x18mm, Φ130XΦ82x16mm, 125XΦ82x15mm. Cold-rolled steel bar specifications include: Φ4, Φ4.5, Φ5, Φ6, Φ7, Φ8, Φ9, Φ10, Φ11, Φ12. The service life of the roll: the service life of the tool steel roll is more than 200 tons, and the service life of the tungsten carbide roll ...Read more