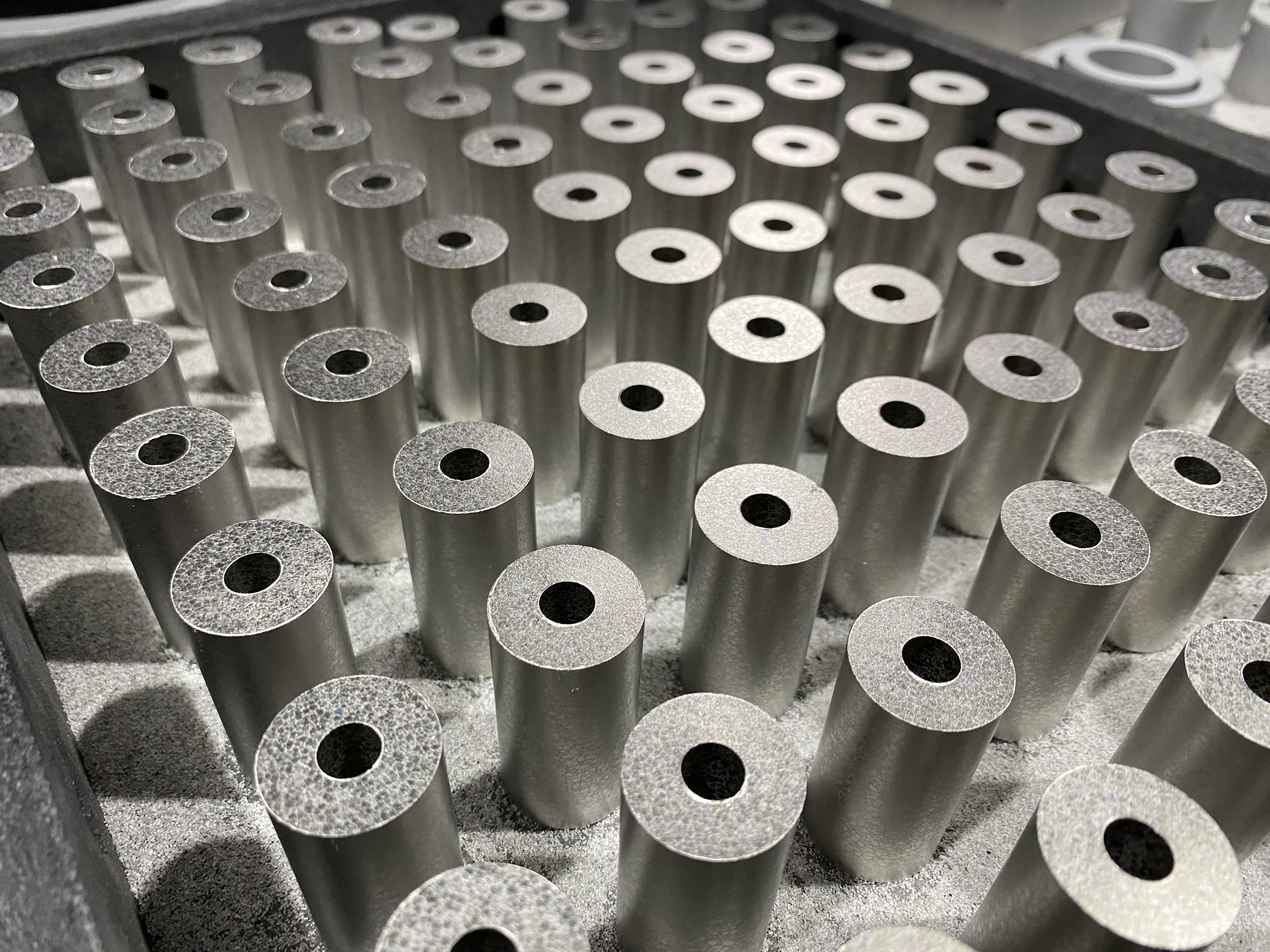

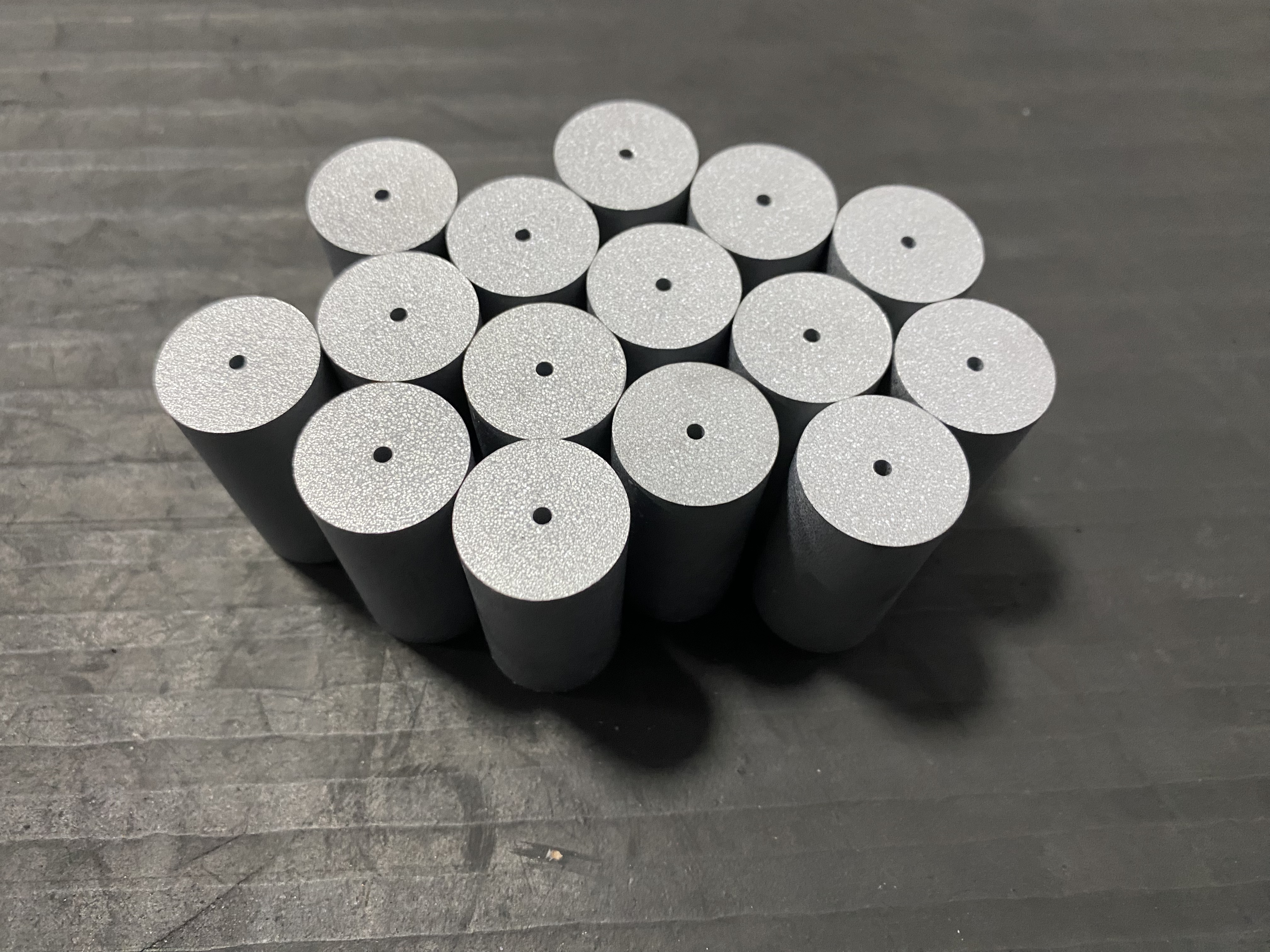

Cemented carbide molding is to compact the mixed powder to obtain the required density and density uniformity, and the required shape.

The process of producing compact shapes and dimensional accuracy requires that the compacted compact must have a certain strength. The relative density of the compact is generally around 50%

On the right, the compact density is too low and sintering cannot be completely densified. If it is too high, pressing cannot be completed or defects such as compact delamination and cracks may occur. Forming is the most operable process in cemented carbide production and is a key process to ensure the accuracy, apparent quality and internal quality of the carbide blank. There are many molding methods for cemented carbide, such as compression molding, extrusion molding, injection molding, cold isostatic pressing-cut molding, etc.

Among them, molding is the most widely used and widely used. Precision net forming is the precision of cemented carbide products. production development requirements. Different molding methods have different structures of molding equipment and molds. Products with complex shapes that cannot be directly formed by pressing, or products whose batch size is too small and it is uneconomical to make another set of pressing molds, are supplemented by press machining.

Post time: Jan-05-2024