News

-

The third to fifth years of the “Five-Year Plan”

Ensure that the “eight realizations” are achieved as scheduled: achieve zero accidents in safe production; achieve the forging of a professional and excellent management team of cadres, transforming from a practical type to a management type; realize the strong alliance of cadres, com...Read more -

Let’s move forward hand in hand, continue to struggle, and achieve greater success

2024 is the year for Renqiu Hengrui Cemented Carbide Co., Ltd. to fully implement the company’s core values and deepen reforms. It is the year for the completion of the high-end industrial base of Hengrui Alloy Plant No. 2, and it is the year of turning point for the international cemented ...Read more -

The first and second factories of Renqiu Hengrui Cemented Carbide Co., Ltd. were established and summarized and commended.

The first and second factories of Renqiu Hengrui Cemented Carbide Co., Ltd. were established and summarized and commended. In 2023, through the unremitting efforts of all Hengrui Alloy personnel, gratifying results were achieved in scientific research, production, sales, and service. Work effecti...Read more -

What is tempering?

Tempering is a heat treatment process that heats quenched alloy metal products or parts to a certain temperature, holds them for a certain period of time, and then cools them in a certain way. Tempering is an operation performed immediately after quenching, and it is usually the workpiece that un...Read more -

What is alloy material quenching?

Quenching of alloy steel is to heat the steel to a temperature above the critical temperature Ac3 (hypoeutectoid steel) or Ac1 (hypereutectoid steel), keep it warm for a period of time to make it fully or partially austenitized, and then cool it at a temperature greater than the critical cooling ...Read more -

Alloy material heat treatment process

The heat treatment process of cemented carbide workpieces includes the steps of: heating the cemented carbide workpieces to 500°C to 1300°C by induction heating, and then cooling. The heat treatment process provided by the invention does not require heat preservation, is simple, short in time, an...Read more -

Effect of cryogenic treatment on improving the quality of cemented carbide

Since the 1980s, cryogenic treatment has been successfully used to optimize cemented carbide. Many studies have shown that cryogenic treatment has a certain positive impact on the mechanical properties, wear resistance, cutting performance, microstructure, and residual stress conditions of cement...Read more -

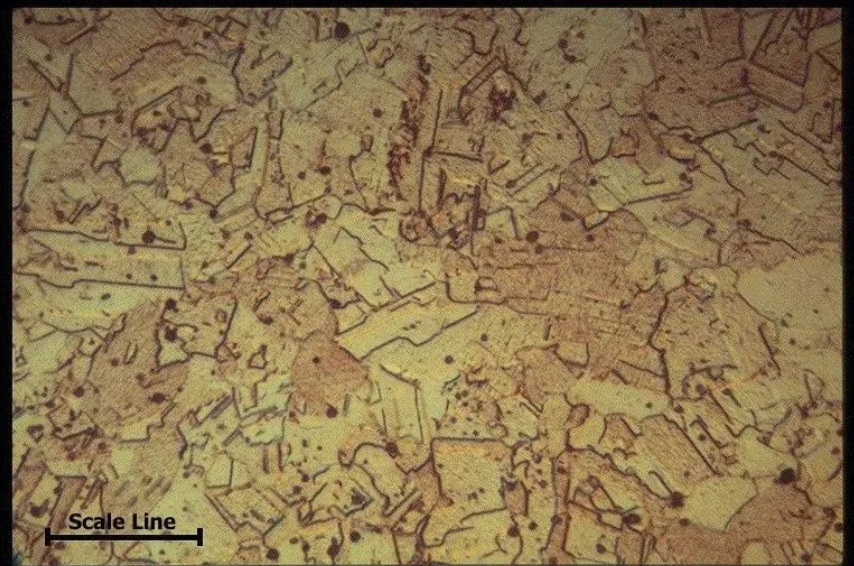

Effect of cryogenic treatment on the microstructure of cemented carbide

Different cryogenic processes cause changes in the properties of cemented carbide, and the changes in properties are closely related to the evolution of its microstructure. Therefore, it is necessary to further analyze the influence of cryogenic treatment on the microstructure of cemented carbide...Read more -

Effect of cryogenic treatment on eta phase

The eta phase is a tungsten-cobalt-carbon ternary compound formed by the participation of some Co atoms during the cooling process after sintering of cemented carbide. The dissolved W in Co cannot form WC. This provides the opportunity for cryogenic treatment to further promote the formation of t...Read more -

Effect of cryogenic treatment on wear resistance of cemented carbide Cemented carbide is an ideal material for wear-resistant parts.

Cemented carbide is an ideal material for wear-resistant parts. However, traditional cemented carbide products can no longer meet the increasingly stringent usage requirements. In recent years, the use of cryogenic treatment technology to make up for the shortcomings in wear resistance of traditi...Read more -

Effect of cryogenic treatment on mechanical properties of cemented carbide

The mechanical properties of cemented carbide are mainly reflected in hardness, flexural strength, compressive strength, impact toughness, fatigue strength, etc. Whether cryogenic treatment can improve the mechanical properties of cemented carbide is the most intuitive expression of the ef...Read more -

Development of cryogenic treatment of cemented carbide in China

Since the advent of cemented carbide in 1923, people have continuously optimized its properties mainly by improving its sintering process, preparing ultra-fine WC-Co composite powder, and surface strengthening. However, due to the problems of complex equipment, high preparation costs, and high te...Read more