Different cryogenic processes cause changes in the properties of cemented carbide, and the changes in properties are closely related to the evolution of its microstructure. Therefore, it is necessary to further analyze the influence of cryogenic treatment on the microstructure of cemented carbide.

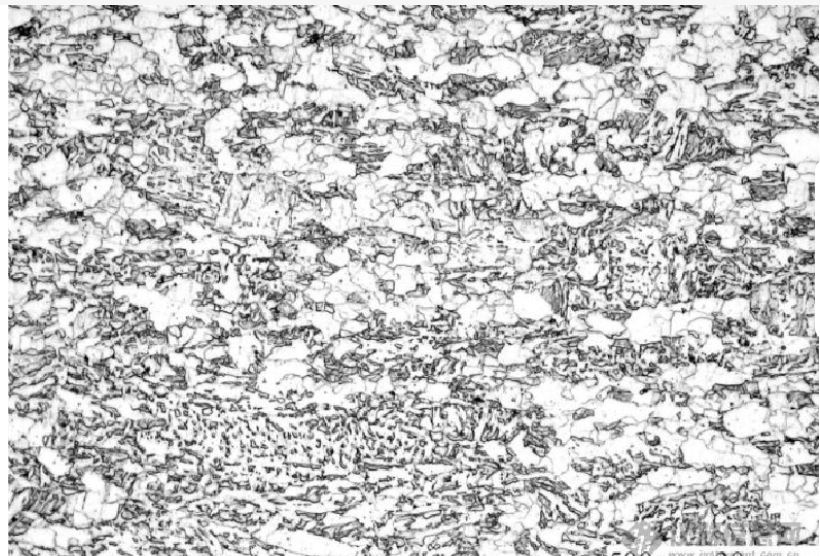

The typical microstructure of WC-Co cemented carbide is as follows: a phase – WC (hard phase); β phase – Co (binder phase); y phase – (TaC, TiC, NbC, WC) equicubic lattice mixed carbides ; eta phase-decarburized phase (CoW, C, Co. W. C). Gill et al. gave a schematic diagram of the a and β phases, as shown in Figure 6. Among them, α phase-WC (hard phase) occupies the main part in the cemented carbide material in the form of a rigid skeleton, while β phase-Co (binder phase) is closely connected with tungsten carbide (WC) like a grid.

When the cemented carbide is cooled after sintering, since a large amount of W and C are dissolved in Co, the high-temperature phase α-Co at room temperature still exists stably. When the temperature continues to decrease, the martensitic phase transformation from face-centered cubic α-Co to close-packed hexagonal ε-Co occurs in the bonding phase -Co. It can be seen that when the temperature changes, there are changes in the microstructure of cemented carbide, which provides the possibility for cryogenic treatment to promote phase transformation of cemented carbide. Many studies have focused on the changes in the microstructure of cemented carbide before and after cryogenic treatment and explored the microscopic evolution mechanism when the macroscopic properties change.

Post time: Mar-06-2024