News

-

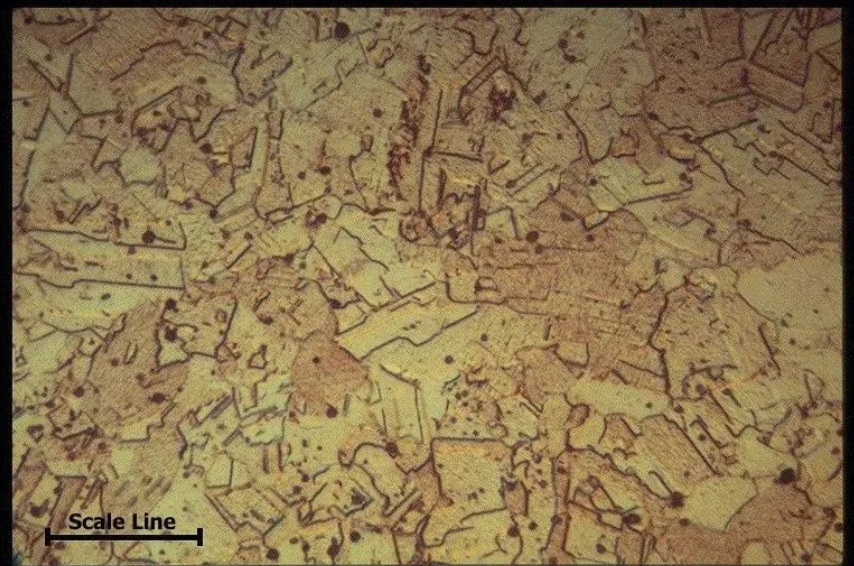

Effect of cryogenic treatment on eta phase

The eta phase is a tungsten-cobalt-carbon ternary compound formed by the participation of some Co atoms during the cooling process after sintering of cemented carbide. The dissolved W in Co cannot form WC. This provides the opportunity for cryogenic treatment to further promote the formation of t...Read more -

Effect of cryogenic treatment on wear resistance of cemented carbide Cemented carbide is an ideal material for wear-resistant parts.

Cemented carbide is an ideal material for wear-resistant parts. However, traditional cemented carbide products can no longer meet the increasingly stringent usage requirements. In recent years, the use of cryogenic treatment technology to make up for the shortcomings in wear resistance of traditi...Read more -

Effect of cryogenic treatment on mechanical properties of cemented carbide

The mechanical properties of cemented carbide are mainly reflected in hardness, flexural strength, compressive strength, impact toughness, fatigue strength, etc. Whether cryogenic treatment can improve the mechanical properties of cemented carbide is the most intuitive expression of the ef...Read more -

Development of cryogenic treatment of cemented carbide in China

Since the advent of cemented carbide in 1923, people have continuously optimized its properties mainly by improving its sintering process, preparing ultra-fine WC-Co composite powder, and surface strengthening. However, due to the problems of complex equipment, high preparation costs, and high te...Read more -

Carbide quenching and tempering process

Quenching process The purpose of quenching is to transform the matrix into martensite and obtain higher mechanical properties. Due to poor thermal conductivity, preheating is required. The hard phase carbides in steel-bonded cemented carbide prevent the growth of austenite grains. After the alloy...Read more -

Resolutely adhere to the bottom line of safe production

Today at noon, the second factory of Hengrui Cemented Carbide Co., Ltd. conducted safety production education. 1. Huang Yafei, director of the tungsten carbide pressing workshop, conveyed the approval of our city’s Safety Committee Office on doing a good job in safety production during the nation...Read more -

Current status of my country’s cemented carbide product exports

The average price of my country’s cemented carbide products is much lower than that of imported products, but the average price of export products has increased rapidly. According to statistics, the average unit price of my country’s imported cemented carbide products will increase by...Read more -

Current status of cemented carbide

Cemented carbide is made of tungsten carbide powder (hardened phase) of high-hardness refractory metal as the main component, and metals such as cobalt and nickel (binder phase) as binders. It is ball milled, pressed, and sintered with extremely high Alloy material with high hardness and good wea...Read more -

Unify our thoughts, reach consensus, strengthen our beliefs, and move forward boldly

The second factory of Hengrui Tungsten Carbide Alloy Company is a new factory area. The personnel need to have a new look. In order to make changes in the high-end cemented carbide industry, the difficulty is getting orders. We must work hard to highlight a new word, new era, new journey, new act...Read more -

Hengrui Company Summary Meeting

This afternoon, all the cadres of Hengrui Cemented Carbide Co., Ltd. listened to General Manager Liu’s teachings in the conference room on the first floor of the second factory. Combined with the current situation of Hengrui Alloy Company, we review the development process, talk about gains...Read more -

The role of tungsten carbide in cemented carbide composition

Tungsten carbide plays a vital role in the production of cemented carbide. Tungsten carbide is an important additive that can improve the hardness and wear resistance of alloys, giving them higher strength and durability. In the production of cemented carbide, tungsten carbide is usually mixed w...Read more -

What are the hardest metal alloys?

1. Titanium alloy Titanium is an important structural metal developed in the 1950s. Titanium alloys are widely used in various fields because of their high strength, good corrosion resistance, and high heat resistance. Many countries in the world have recognized the importance of titanium tungste...Read more