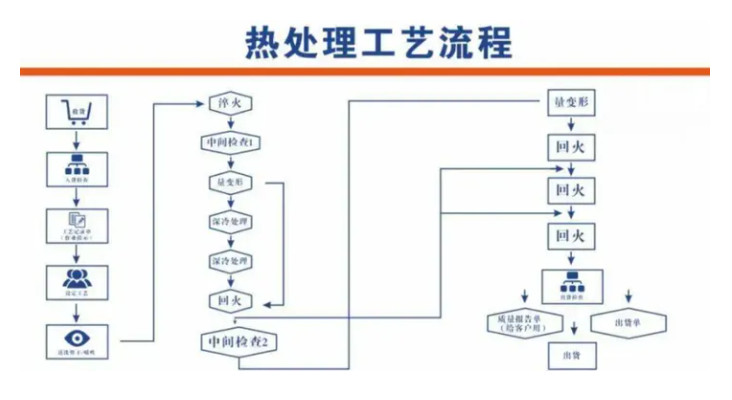

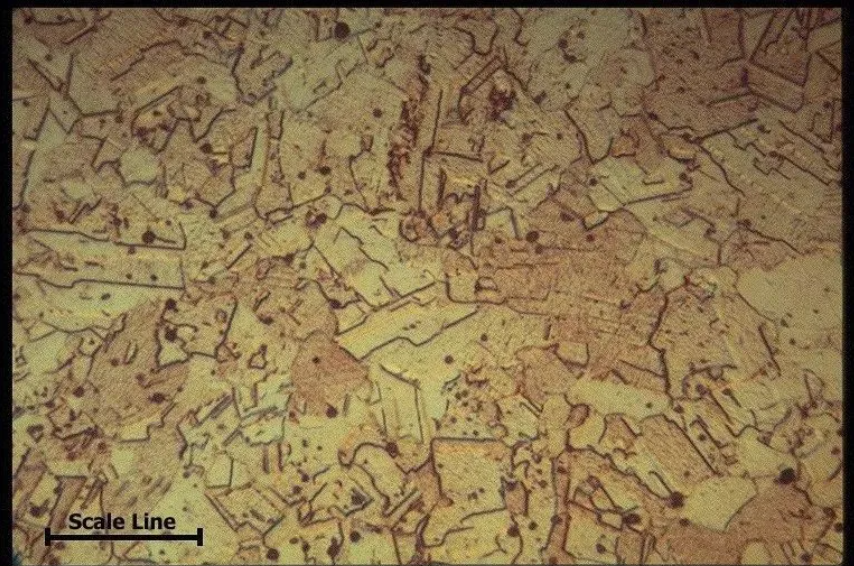

The heat treatment process of cemented carbide workpieces includes the steps of: heating the cemented carbide workpieces to 500°C to 1300°C by induction heating, and then cooling. The heat treatment process provided by the invention does not require heat preservation, is simple, short in time, and highly efficient, and can promote the widespread application of heat treatment in cemented carbide. Heat treatment refers to a metal alloy thermal processing process in which the material is in a solid state and obtained by heating, holding and cooling to obtain the expected structure and properties.

For example, we often use the quenching and tempering process (double heat treatment, quenching and tempering). That is, after quenching, it is subjected to high temperature tempering treatment. Such as 45 steel, 30CrMOV9, tungsten-nickel alloy, tungsten carbide alloy and other metal materials, the higher the carbon content, the higher the hardness after heat treatment.

Post time: Mar-12-2024