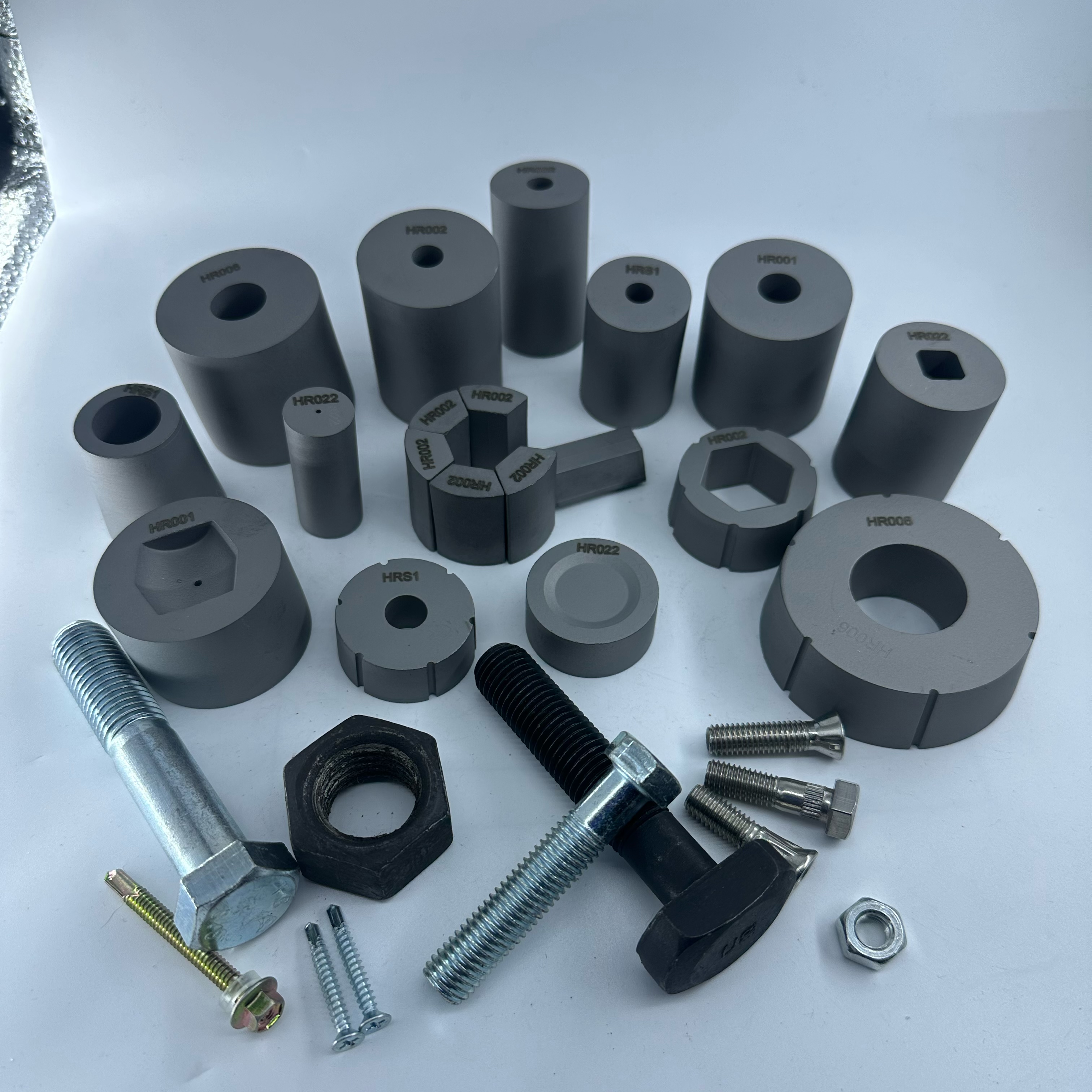

Polish Surface WC + CO Carbide Cold Heading Dies

Quality assurance:

- Every production process has a special person to test to ensure quality

- Have professional engineers to check the quality

- All products are under strict quality system management based on ISO9001:2008

YG22C tungsten carbide pellets

1.Widely used as cold punching mould and forging mould.

2.Non-standard sizes of carbide pellets based on customer requests.

3.All carbide pellets are strictly inspected by ultrasonic flaw detector to avoid blowholes or cracks to ensure the quality.

4.Material:100%Virgin material with submicron grain size.

5.High wear resistance,high hardness and impact toughness.

6.We can provide blank or deep finished products with precision grinding and polishing.

1.Strong R&D team. Professional engineers serve for clients, recommending product and grades as per your applications. We also offer after-sale service.

2. Strong Mould R&D team. We support products customization as per requirements, and ensure high working efficiency and product quality.

3. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC. Tungsten Carbide Cold Forging Die

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against T/T before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.