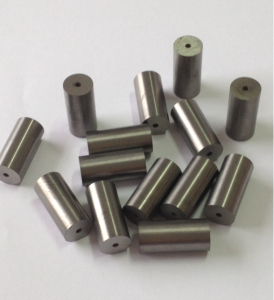

GT40 Cemented Carbide Cold Forging Die YG11 high impact-resistant

1. Made by virgin raw material. Our production line is imported, the service life time of product is higher by 120%. cold punching dies

2. Don't crack.

3. HIP (Hot Isostatic Press) sintering ensures the stable microstructure, the service life time is longer, die change is less, can improve the working & production efficiency.

4. We also supply carbide dies with coarse grain size, which has high impact resistance ability and can be used to make big size carbide dies.

| Product Name | tungsten carbide cold heading pellets |

| Material | Hard metal |

| Size | OD55xID24x50 |

| Size Tolerance | According to the drawing |

| Color | Sliver grey |

| Recommend Grade | G40 |

| Grain Size | Coarse Grain Size |

| Application | screw,nuts |

| Processing Treatment | HIP sintering |

| Product Features | Long life, wear resistance |

| Certification | ISO9001-2015 |

The cost is reduced by increasing tool life and productivity is improved.

The defect rate is reduced and quality is improved.

High fracture toughness------- lower crack occurrence

High strength and hardness-------improved tolerance of colt

Low friction coefficient------improved surface roughness

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC. tungsten carbide pallets

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against T/T before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.