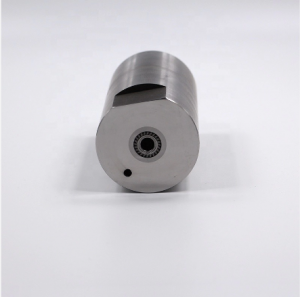

Screw Second Punch Dies Punch Pin Cold Heading Machine Dies

High impact, good wear resistance

sizes & types are available

Well grounded and blanks are available

100% pure raw material & direct factory produce and selling

Advanced equipement

Skilled technician

Many sizes & types, OEM is available

Trial order is welcomed

ISO certificate

High Hardness and High Wear Reaistance

Hengrui Cemented Carbide Are Harder and Better Wear Resistance,does Not Wear out Too Much,because of Long Use.

Does Not Strain the Surface of the Machined Part

The Products Are Smooth and Smooth, and the Role of Nanometer Diamond Coatings, gives the Products an Excellent Surface Finish and Low Friction, will Not Damage the Surface of the Part.

Corrosion Resistance

Good Oxidation Resistance, generally, it is Very Resistant to Atmospheric, acid, and Alkali Corrosion, not Easy to Oxidize, and Can Maintain the Integrity of the Products.

Wide Range of Applications

Widely Used in Various Industries for Drawing, forming and Shaping Dies. such As Stainless Steel, tableware, metal Utensils, hardware Accessories Etcs.

- YG6X: Good toughness, wear resistance, corrosion resistance and thermal crack resistance. Used in most stands of the finishing mills and in the rear stands of common mils.

- YG8: Good toughness and thermal crack resistance, good for general purposes. Used in most stands of the finishing mills and in the rear stands of common mils.

- YG11: Good impact resistance. Used in the stands of pre-finishing rolling mills for hot rolling rebars and they can be machined with turning and milling.

- YG15: Good impact resistance. Used for hot rolling rebars and in the first and second stands of pre-finishing rolling mills and they can be machined with turning and milling.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.