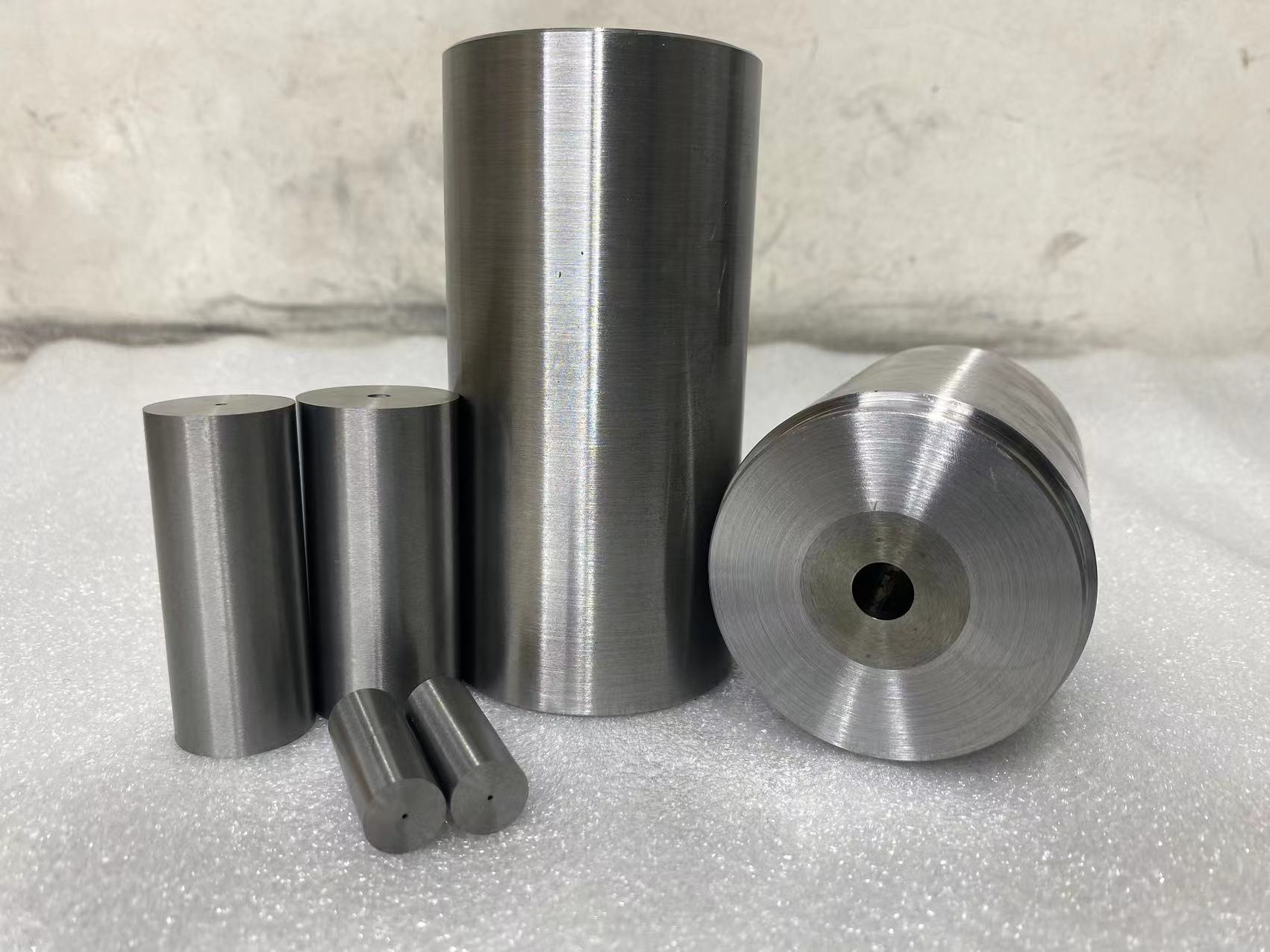

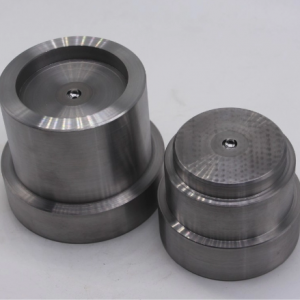

Cemented Carbide Cold Heading Stamping Dies for Screws Bolt And Nut

High cobalt fine particles, good toughness, good wear resistance, suitable for processing screws below M16mm and drywall screws, dovetail nails, small standard screws, small reduction rod molds, six-piece molds, nut molds, black material product shrink rods Comes with racquet cap and light punch.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Our products have passed ISO9001 quality certification. All products will be sold after passing 11 tests such as hardness, magnetic saturation, and bending strength before shipment.

Usually 50% T/T in advance, balance 50% before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.