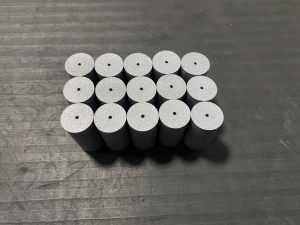

Tungsten carbide heading die blanks to make standard bolts

HengRui Carbide Die, a dedicated tungsten carbide products manufacturer in area of cold forming for metal parts. We specialize in designing and building cold forging dies in fully – automated multi – stage former. Whether that forging dies are intricate shapes or relatively large ones.

In China, The HengRui Carbide Die is a competent and reliable partner for the cold forming industry, and building a strong reputation for qualify and timely services. With nearly two decades of the experiences on its side, we realize customer’s requirements of dimension tolerance, tool life and processing smoothly, and applying our experiences gained from serving a multitude of industries has proven beneficial to all of our customers.

1.Tungsten carbide die blanks are used for finishing casting mould, punch dies, wire drawing die, machine mold, progressive die, extrusion die, press mold, mould parts, trimming die, cold heading die, forging mold, cold forming die etc.

2. RenQiu HengRui has the most stock of available moulds for various sizes of carbide dies which saving a lot cost for our customers.

3. RenQiu HengRui has the most wide and stable grades for carbide dies and has highest cost performance comparing to Kennametal, Cbcarbide.

4.We have grade similar to G5/G20,GT55 or G20,G30,G40,G50

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 7days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.