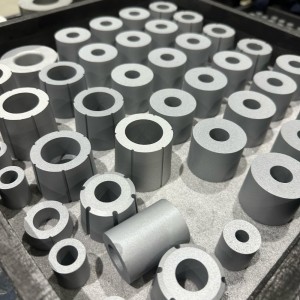

High Toughness Tungsten Carbide Cold Heading Dies / Cemented Carbide Heading Dies

1. Chinese factory specialized in processing and production, ISO certification.

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

1.Cemented carbide pellets are widely used in cold heading dies and punching dies

for manufacturing nuts, bolts and many other products.

2.The grade GT55/YG25C is the most widely used material in making carbide pellets.

It has excellent properties which lead to good performance and long service time.

3.Except for the standard sizes, nonstandard sizes of carbide pellets

can also be produced according to customer's requirements.

4.All carbide pellets inspected strictly with ultrasonic flaw detector

to avoid ones with blowholes or cracks leaving the factory.

| Tungsten Carbide Cold Forging/heading Dies | ||||

| Grades | Density | T.R.S | Hardness | Performance & application recommended |

| g/cm³ | MPa | HRA | ||

| YG11 | 14.4 | ≥3000 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

| YG15 | 14 | ≥3400 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, forging tools under large stress. |

| YG20 | 13.5 | ≥3800 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. |

| YG15C | 14 | ≥4000 | 86.5 | For oil cone drill bits, cut medium soft and hard rocks; debarking and cutting of frozen wood, soft wood and original wood. |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging dies. |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

| YG20C | 13.5 | ≥3800 | 83.5 | Dies for wear resistant or impact resistant application. |

| YG22C | 13.3 | ≥4000 | 83 | Nut forming dies and high impact resistance forging dies. |

| YG25C | 13.1 | ≥4250 | 82.5 | Stainless bolt header dies and rollers. |

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Tungsten Carbide Cold Forging Die

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

Cemented carbide pellets are widely used in cold heading dies and punching dies

for maufacturing nuts, screw caps, bolts, cans and many other products.

1. Good corrosion resistance.

2. High precision.

3. Ra0.2 surface roughness.

4. Made from 100% virgin raw material.

5. Produced go through in-process and final inspection.

6. Stable and continuous production ability.

1. Feedback within 48 hours;

2. Good English communication;

3. Professional suggestion on product;

4. Good training export sales person;

5. Skilled in tungsten carbide sell;

6. After sales service.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% T.T before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.