Fo/RO/Rt/Pr/Ca Roller Tungsten Carbide Roll for Cold Rolling Ribbed and Smooth Wire

1. Chinese factory specialized in processing and production, ISO certification.

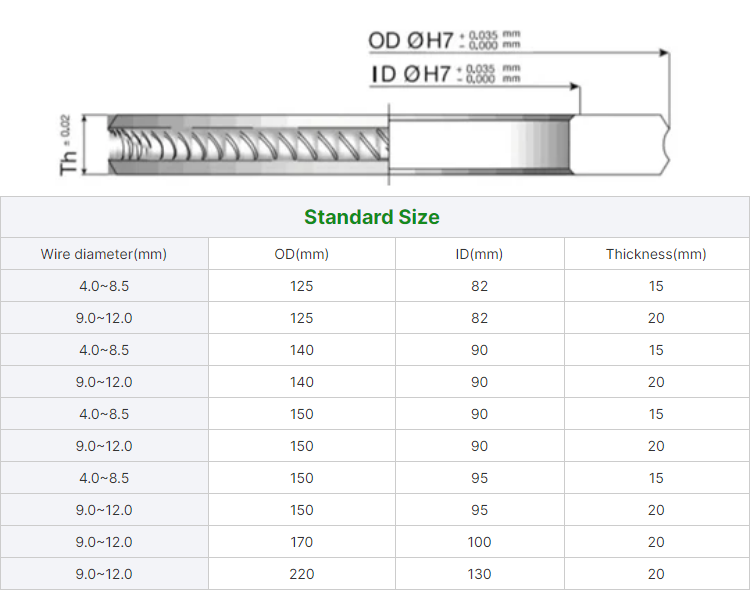

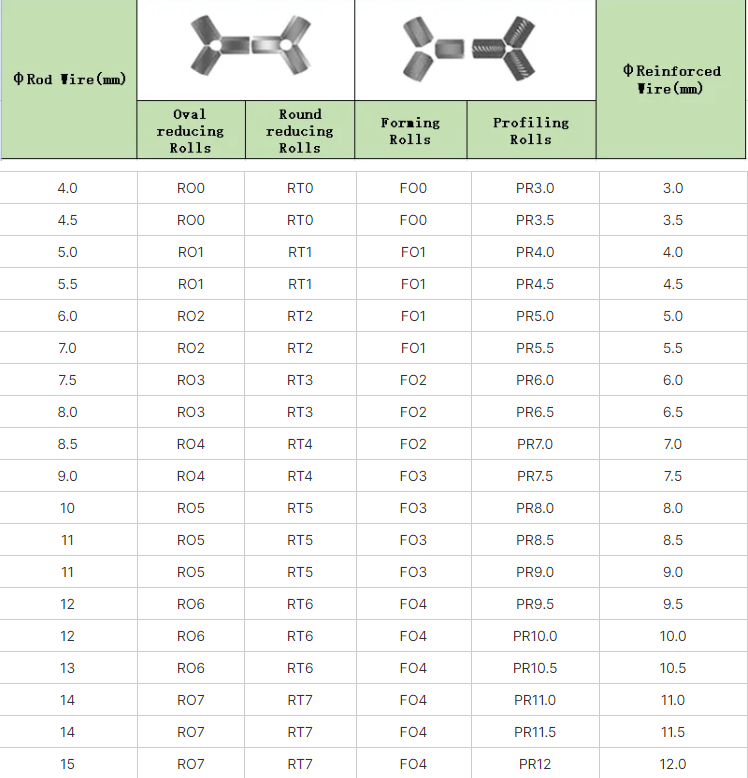

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

Benefit from the application of the most modern production methods and the use of the high quality materials, as well as our most experienced employees who manufacture the tungsten carbide rolls, Miller defines a new standard in wire reduction. and increased wire quality through improved surface finishing and rib geometry. WIRE MESH ROLL When choosing the right carbide rolls for your production needs, it's important to evaluate the load and speed requirements of your manufacturing process. The load refers to the amount of force that the rolls will need to withstand during operation, while the speed refers to the rotational speed of the rolls. Both of these factors can impact the durability and performance of the carbide rolls. Miller can help you determine the load and speed requirements for your specific production needs and recommend the appropriate carbide roll.

1. Tungsten carbide rolls can last up to 50 times longer than conventional, hardened tool steel rolls

2. Guaranteed product performance, save more time and work efficiently

3. Solves excess wear problems on any roll section of the mill

4. Fewer changeovers, due to excessive wear on hardened tool steel rolls

5. Holds tighter tolerances on tube and pipe

6. Tungsten carbide rolls should be considered, when high footage/tonnage is required from any one particular size

7. Eliminates pick-up to give tube and pipe a better surface finish

8. Rolls can be solid carbide on smaller mills or carbide-inserted for larger rolls

9. Miller's design expertise can assist in cost justification

10. Drag finished roll surface for the best wire quality

11. Grinding of all profiles and markings

12. Optimum chemical composition and physical properties of carbides

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering YG15 carbide ring roll , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 10-15 days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% T/T before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.