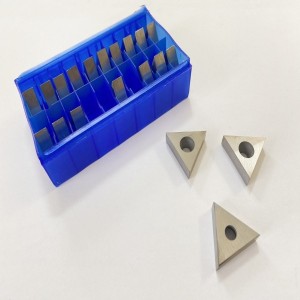

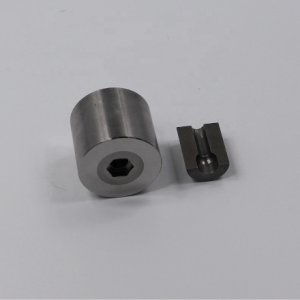

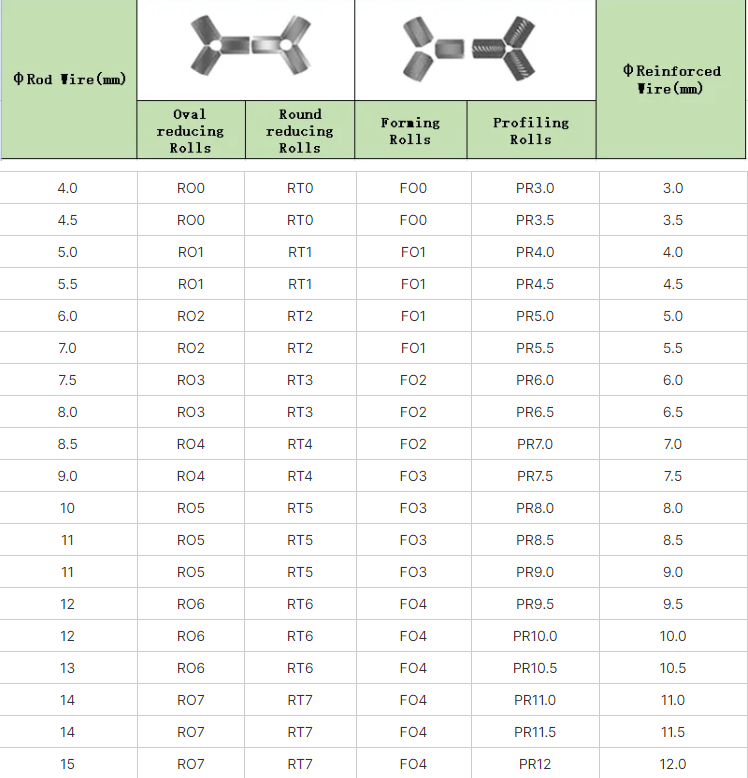

Custom OEM/ODM tungsten carbide roller PR PO FO RO RT for rebar

Tungsten Carbide is not affected by changes in the environment or external temperature so these carbide roller can be used in either extreme heat or extreme cold.

Tungsten carbide rollers are valued for their hardness and resistance to corrosion and, since they can withstand an elevated level of stress, they are the ideal choice for clients in the aeronautic and aerospace industries, the automotive industry and the bearings industry. They are often found in power steering columns or transmission and navigation equipment and can also be used for vibro finishing.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

The quality assurance of cemented carbide rolls usually includes the following aspects:

Raw material selection: High-quality carbide rolls generally use high-quality carbide materials to ensure uniform composition and good mechanical properties.

Manufacturing process: The manufacturing process for producing cemented carbide rolls should strictly comply with standards to ensure that the processing accuracy and surface quality of the rolls meet the requirements.

Quality inspection: Carbide rolls undergo quality inspection during the production process, including physical performance testing, surface quality inspection, etc., to ensure that the product meets standard requirements.

Service life and performance guarantee: Provide a guarantee or commitment on the service life and performance of carbide rolls to ensure that they can achieve the expected results under specific conditions.

After-sales service: Provide after-sales service for carbide rollers, including handling of product quality issues, technical support, etc., to ensure that customers can receive timely support and help during use. The above is the general quality assurance content of cemented carbide rolls. Specifics may vary by manufacturer and product type. When choosing carbide rolls, it is recommended to fully communicate with the supplier or manufacturer to understand the detailed quality assurance situation.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% before delivery.. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.