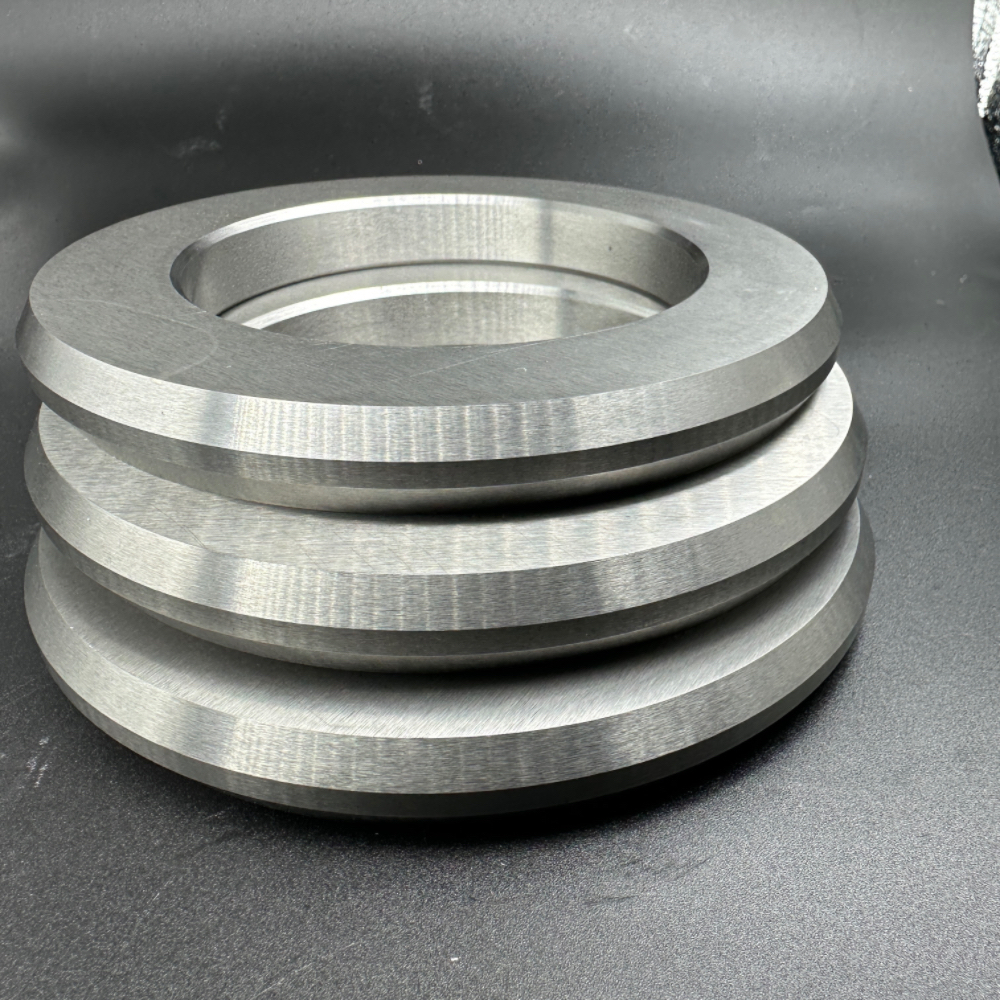

Φ 150XΦ 90X15mmm RO Tungsten Carbide Triple Indent Rollers for Wire Rod Mills

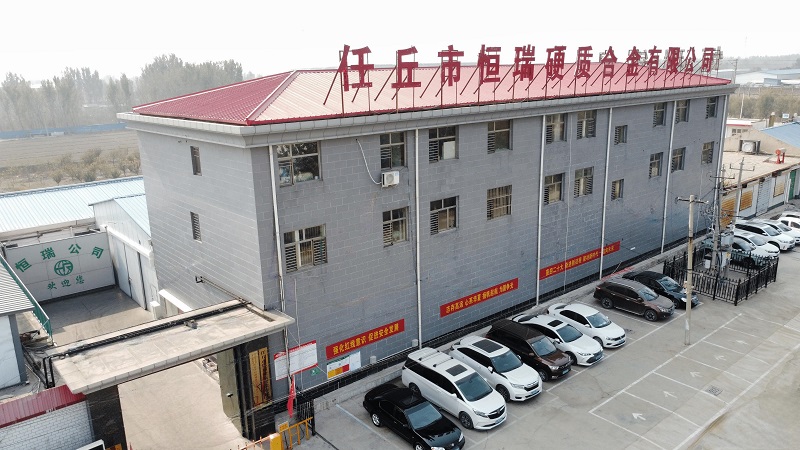

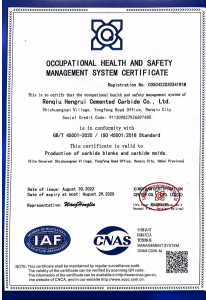

Renqiu Hengrui Cemented Carbide Co., Ltd. is a joint-stock company registered in Renqiu City, Hebei Province in 2006. Its registered address is located in Shizhuang Nancun Industrial Zone, Renqiu City, Cangzhou City

The unified social credit code/registration number of Renqiu Hengrui Carbide Tool Factory is 911309827926697480. The corporate legal person is Wu Baozong. The company is currently in business.

In 2011, China's cemented carbide output was 23,500 tons, the cemented carbide industry sales revenue was 20.9 billion yuan, cemented carbide exports were nearly 5,000 tons, export earnings exceeded 360 million US dollars, and the output of cemented carbide deep processing products reached 6,600 tons, accounting for 10% of the total alloy production. 1/3 of the output. The variety of cemented carbide products produced is basically complete, with more than 40,000 specifications and models. The output and variety can basically meet the needs of various economic fields in China.

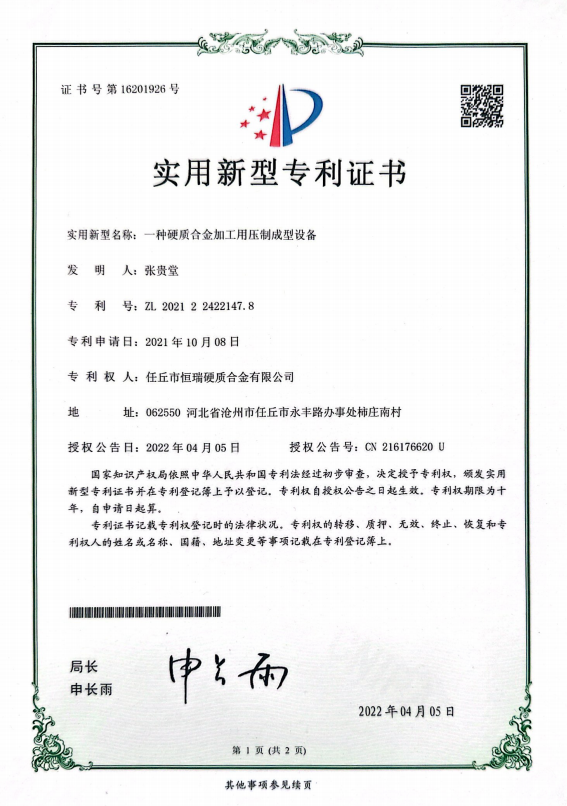

Powdering → Formula according to application requirements → Wet grinding → Mixing → Crushing → Drying → Sieving → Then add molding agent → Dry again → Sieve to prepare the mixture → Granulation → Cold isostatic pressing → Molding → Sintering → Forming (blank) → packaging → warehousing.

Contact Us