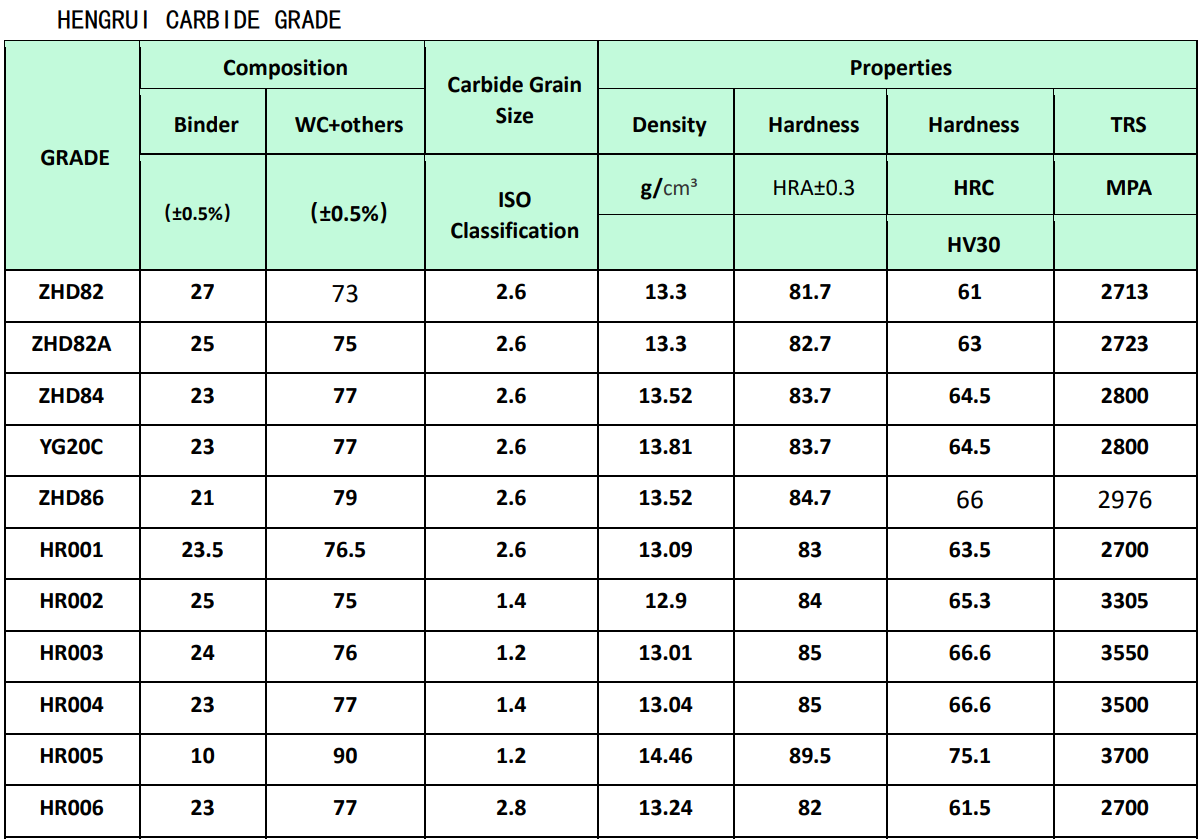

BK20 BK30 Cemented carbide cold heading pellets for stainless steel mild steel screws and nuts

1. We do not use recycled materials

2. We can help you solve all problems caused during processing

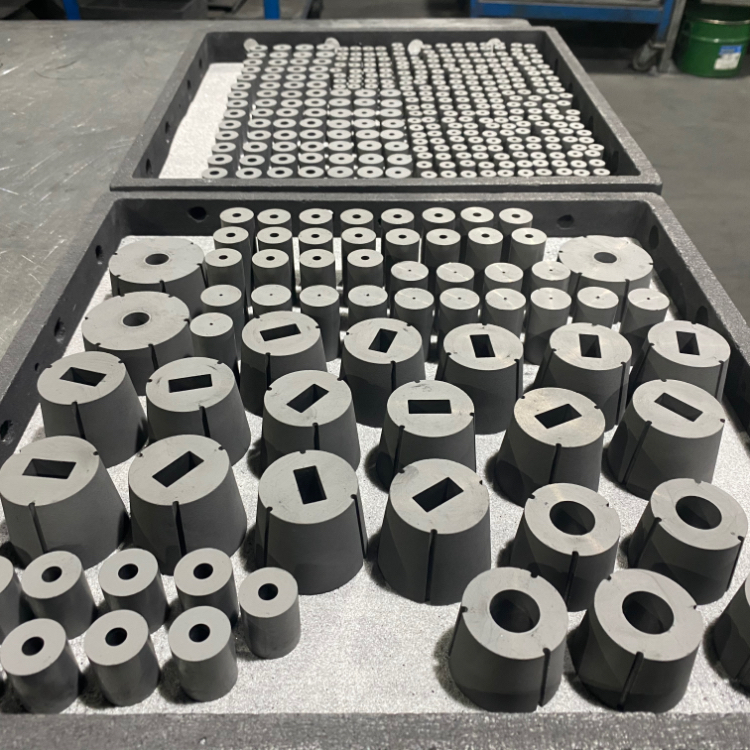

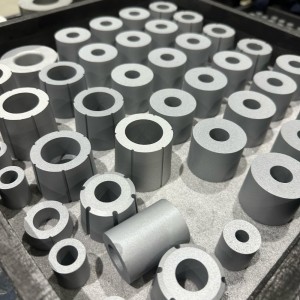

3. We can provide semi-processed products, finished products, and blanks

4. We are the most professional cold heading mold supplier in China

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

We focus on the cold heading mold industry. We are well aware of the importance of powder metallurgy casting molds to industrial production and are committed to providing customers with high-quality, high-efficiency die-casting mold products and services. Our manufacturers have rich production experience and advanced technical equipment, and can meet various needs for mold production. We focus on quality and strictly control every production link to ensure that every product meets customer requirements.

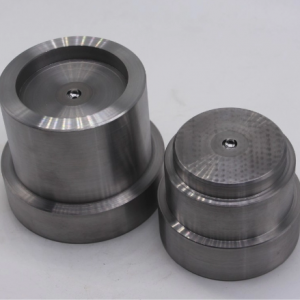

1. It has high hardness and strength to ensure that the mold is resistant to pressure, wear, deformation and adhesion during work;

2. It has high wear resistance to ensure that the shape and size tolerances of the mold change within a certain range during long-term operation and will not fail due to excessive wear;

3. Have sufficient toughness to prevent the mold from brittle fracture under impact load;

4. The heat treatment deformation is small to ensure that the mold will not be scrapped due to excessive deformation during heat treatment;

5. It has high thermal hardness to ensure that the mold will not soften due to temperature rise during high-speed stamping or heavy-load stamping processes.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Delivery takes 3~10 days after receiving deposit