Round Reducing Tungsten Carbide Cold Roller (RT) with Good Wear Rear Resistance

1. Chinese factory specialized in processing and production, ISO certification.

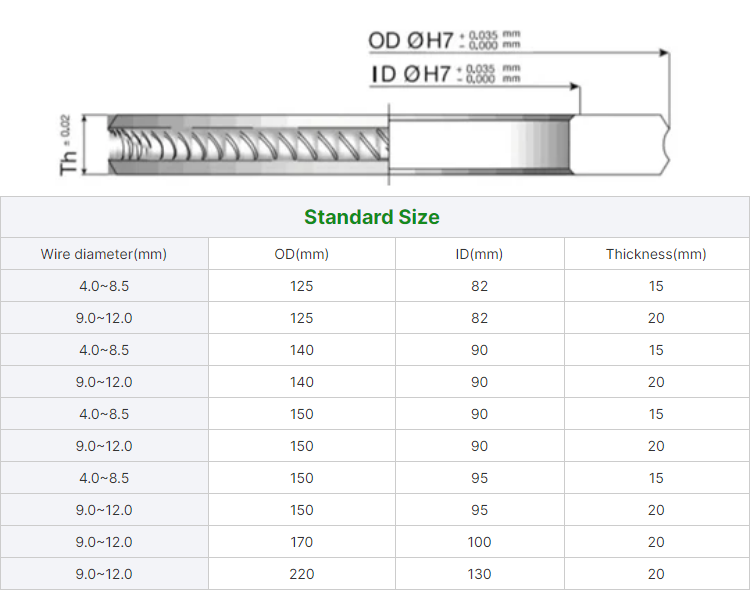

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

Tungsten carbide rollers,also called as tungsten carbide wire mesh rolls,is applied in reinforcement wire cold rolling and forming mills in construction industry,thread steel bars are with the durability 10 to 20 times higher compared to common steel roller,and the surface quality and the steel bar size accuracy are greatly improved.

Oston tungsten carbide rollers are produced by isostatic suppressing and HIP sintering,which are the most advanced facilities to ensure the stable properties,which reduces the production cost and improves the rebars quality with high precision on dimension,clear ribs and beautiful surface.

Tungsten Carbide Roller for Cold Rolling Cassette Producing Reinforcement Steel Wire Mesh Roll PR2.5/PR3.5/PR4.5/PR5.5/PR6.5/PR7.5/PR8.5/PR9.5

Our tungsten carbide products are applicable to the production of wire mesh, steel wire nails, fasteners, cables and oil and gas, and plastic. We welcome your enquiry for your own specific requirements.

Our full range of equipment satisfies a broad range of needs and demands for the market. Thanks to our advanced engineering departments, and continuous research and development, STAR company is able to study and develop cost effective, hi-tech solutions that provide tangible economic benefits to the end user.

As one of the biggest tungsten carbide manufacturers in Zhuzhou, China, we are firm in our original intention, brave to innovate, and continue to move forward, striving to be the first-class carbide manufacturer in China and creating a world renowned brand. STAR CARBIDE is your right solution for tungsten carbide.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 10-15 days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% T/T before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.