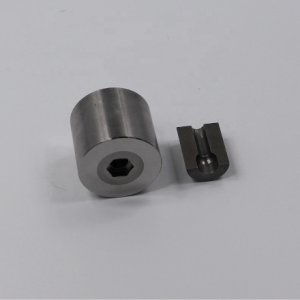

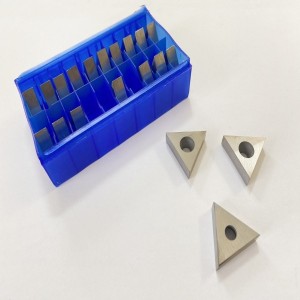

Tungsten Carbide Hot/Cold Wire Forming Rolling Mill Roll

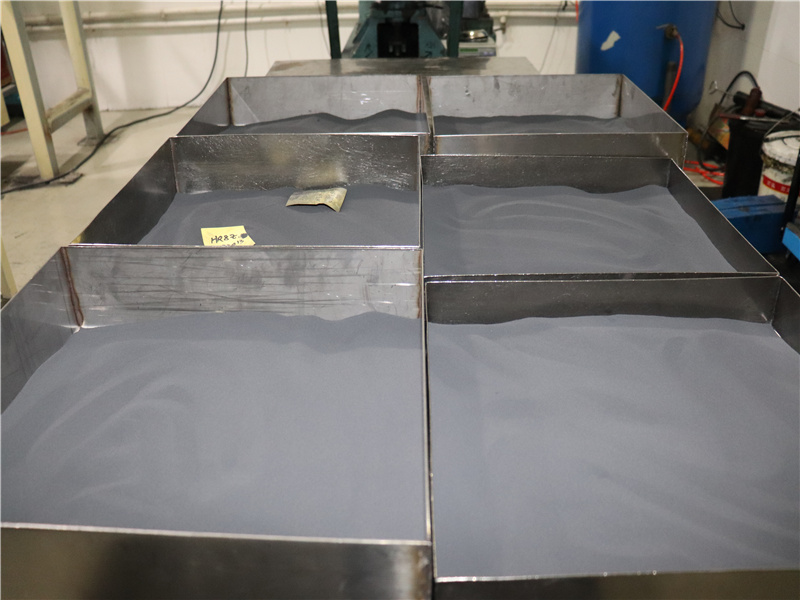

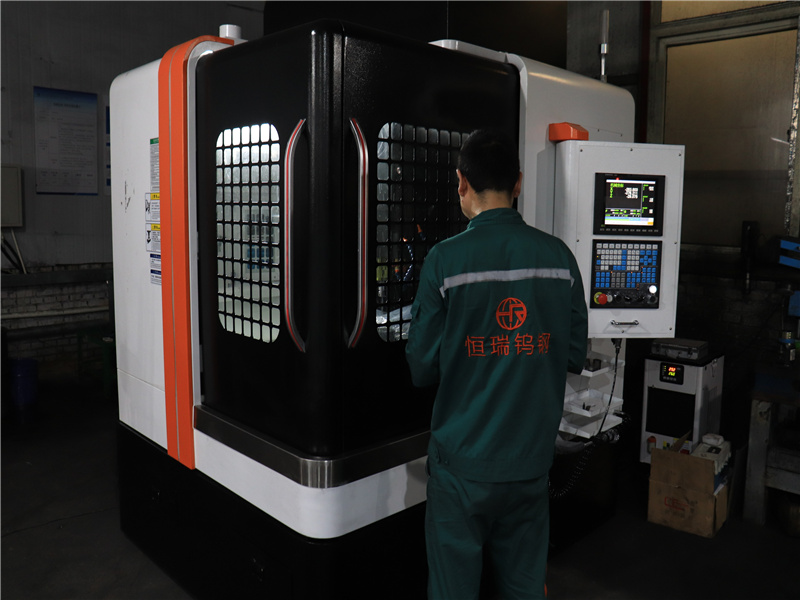

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

WC roll rings are subjected to high temperature, rolling stress, thermal corrosion and impact load in the hot rolling process. Compared with WC roll rings produced abroad, there are still some gaps in the purity of raw materials, processing technology and performance indexes of roll rings manufactured in China, and the wear resistance of rolls in use is poor and the roll rings are prone to breakage. Based on the ordinary carbide roller ring material, Lubrication GradientMaterial (LGM for short) is used to develop the gradient material LGM roller ring.

The technology is to add sulfur and oxygen to the ordinary carbide material to form stable gradient metal oxides and metal sulfides (Co3O4 and CoS, respectively) on the surface of the metal base material. The industrial test of LGM roll ring shows that the sulfide and oxide in the gradient material can reduce the friction coefficient during rolling, significantly improve the lubrication performance of the roll ring under high temperature and large rolling force, reduce the generation of transverse cracks, and the service life of the roll ring is 1.5 times that of ordinary carbide roll ring, and reduce the amount of resharpening and roll change. The service life of the roller ring is 1.5 times longer than that of ordinary carbide roller ring, and it can reduce the amount of grinding and the number of roller changes, which has significant economic benefits.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.

Q1: Why did you choose us?

A1: We are the factory, we offer our clients are all wholesale price and best quality.

Q2: Do you provide free samples?

A2: Yes, we welcome all clients to get free samples for testing under the condition of freight paid by customer.

Q3: What is your minimum order requirement?

A3: We hope you clear your quantity, if you do not have, we will indicate the MOQ for each item in the quotation sheet. We welcomethe sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

Q4: What is the delivery time of your products?

A4: It depends on the inventory availability. If items needed are in stock, the delivery time would be within 7 work days, but if not thedelivery time would be around 7-30 work days.

Q5: What kinds of production do you supply?

A5: We can produce both standard production and special production. Based on your request, drawings