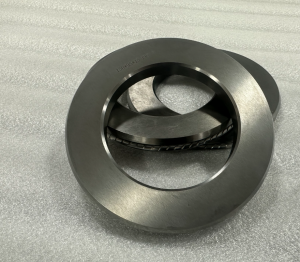

Tungsten Carbide Wire Rolls

1. Chinese factory specialized in processing and production, ISO certification.

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

The rolling material of the cold-rolled three-dimensional rolls is cold-rolled ribbed steel bar. The surface quality of the rolled material is high and the surface defects are few, the deviation of the shape and dimensions is small, and the rib marks are clear. At the same time, the properties of the ribbed steel bar are changed and the strength is improved.

The carbide rolls have high hardness, and their hardness changes very little with temperature changes. The hardness at 700°C is 4 times that of high-speed steel; Its elastic modulus, compressive strength, flexural strength, and thermal conductivity are also more than 1 time higher than tool steel. The rolling capacity is 800-1500 tons, which is 20-50 times that of ordinary tool steel.

Due to the high thermal conductivity and good heat dissipation effect of the cemented carbide roll, the time for the surface of the roll to be at high temperature is short, which shortens the high-temperature reaction time between the roll and harmful impurities in the cooling water. Therefore, the tungsten carbide rolls are more resistant to corrosion and cold and thermal fatigue than tool steel rolls.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.