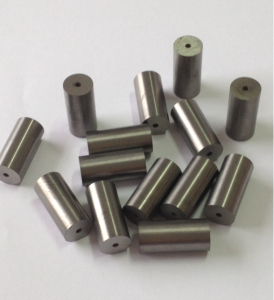

High quality YG15 Roller 3D Tungsten carbide rolls for cold rolling rebars

1. Chinese factory specialized in processing and production, ISO certification.

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

Carbide roller used on the stretch reducing mill for bars, thread steel bars and common wire with the durability 10 to 20 times higher compared to common steel roller. The surface quality and the steel bar size accuracy are greatly improved. The cemented carbide roller reduces effectively the production cost and improves the quality. Roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling, Wire Straightening, Wire Guiding etc.

| Grade | Density | T.R.S | Hardness | Performance & Application Recommended |

| g/cm3 | MPα | HRA | ||

| YG6 | 14.9 | 2100 | 90 | or coring crowns,electric coal drill bits,coal cutting picks,oil cone bits and scraping knife bits, usd in geological prospecting, coal mining and oil well boring. |

| YG8 | 14.7 | 2400 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, cone drill bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YG8C | 14.7 | 2450 | 88.5 | Mostly used as the buttons of small and mediumsized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

| YG9C | 14.6 | 2450 | 87.8 | Suitable to strips, conical buttons for rotary percussion-resistant, geological prospecting buttons, cut soft and medium hard formations. |

| YG10C | 14.4 | 2550 | 87 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

| YG11C | 14.4 | 2600 | 87 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

| YG13C | 14.2 | 2650 | 86.5 | Predominatly for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and vey hard formations. |

| YG15C | 14 | 2700 | 86.5 | For oil cone drill bits, for medium soft and medium -hard rocks. |

| YG15 | 14 | 2500 | 87.5 | Good strength and less wear resistance,for bits of rotary hammer rock drills and heavy rock drills, for hard and very hard rocks. |

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Tungsten Carbide Roller is a kind of metallurgical tool which consists of tungsten carbide and cobalt with high hardness and wear resistance. There are ideal for use in applications where strength, durability and longevity are factors. The performance of the tungsten carbide roller is related to the content of the bonding phase metal and the size of the matrix phase–the tungsten carbide powder particle.The different binder content and the corresponding tungsten carbide particle size form different carbide grades. If the content of the metal binder is increased or the particle size of the tungsten carbide is increased, the hardness of the cemented carbide decreases and the toughness increases. Tungsten Carbide (WC) is twice as strong as steel and is similar to corundum in hardness. Tungsten carbide rollers combine superior hardness with resistance to abrasion and wear and they are available in a wide range of sizes. They can also be milled according to the customer’s specifications. It has advantage of high wear resistance, long life and high efficiency during the high speed rolling.

1. Use 100% tungsten carbide raw material.

2. Stable chemical properties

3. Excellent performance and good wear/corrosion resistance

4. HIP sintering,good compactness

5. Blanks,high machining accuracy/precision

6. OEM customized sizes available

7. Factory’s offer

8. Strict products quality inspection

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.