Carbide Mill Roller for Hot Rolling

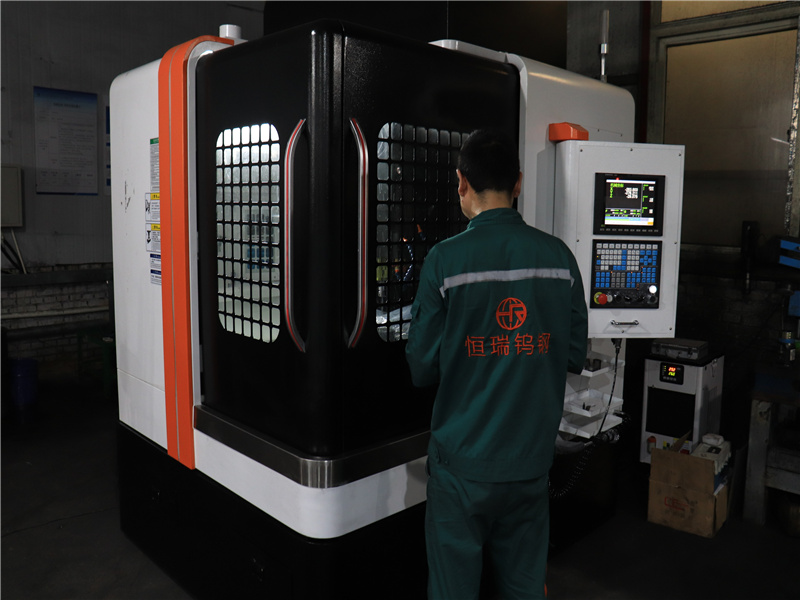

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

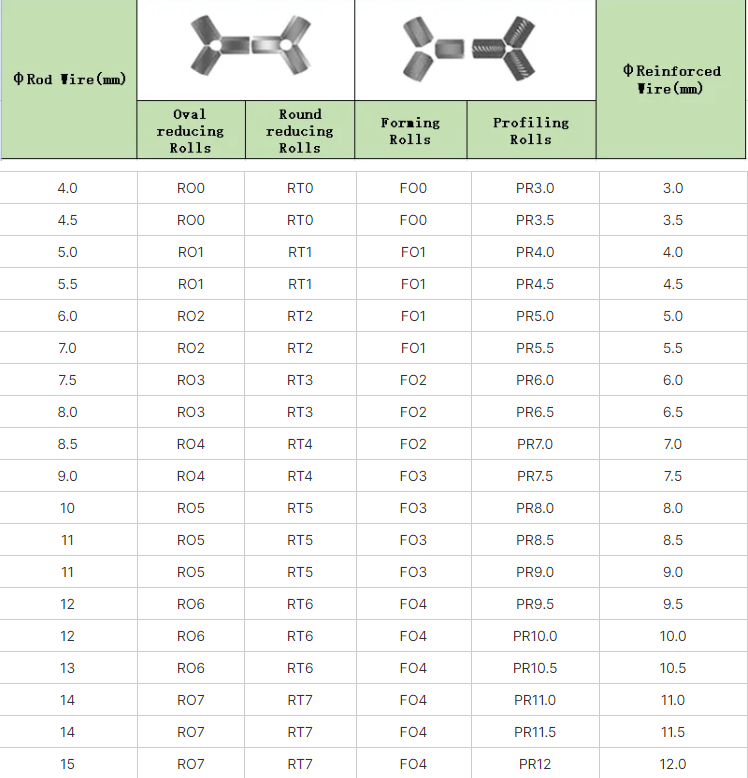

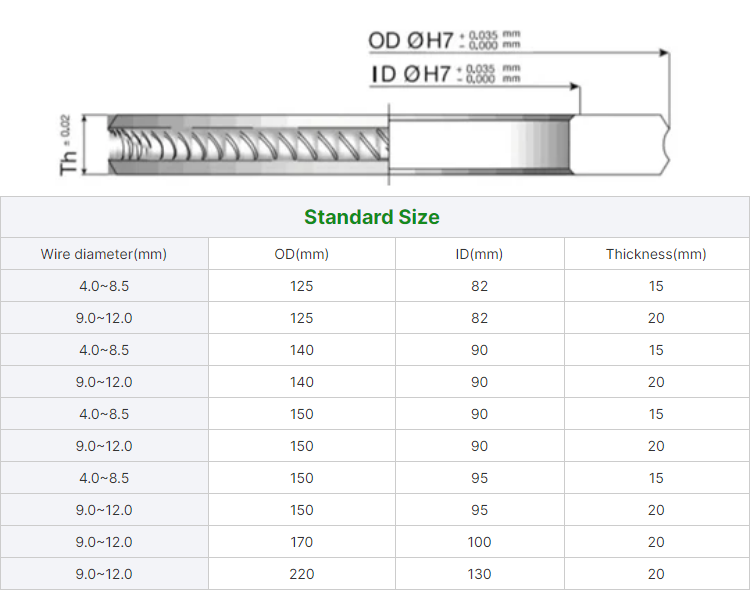

The cemented carbides rolls are divided into the conventional WC-Co alloys and the corrosion resistant alloys with a mixed binder Co-Ni-Cr. The binder contents vary according to the specific requirements of the rolling mill. We also offer composite roll rings that are a combination of cemented carbide and steel. Unlike the relatively brittle cemented carbide rings, these composite rings open up a wide range of applications. These roll rings can be shrunk on the shaft without any clearance between the shaft and the ring, leading to an increased stiffness of the roll shaft and a higher rigidity of the system. For the transmission of higher torques, keyways can be machined in the faces or in the inner diameter of these roll rings. These rings are used in the intermediate stands and blocks with a 3-ring layout as well as stretch reducing tube mills.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.

For intermediate stands of bar and wire rod mills, and finishing stands of bar mills, we have combirolls. This consists of a composite roll ring with a mechanical clamping system, providing a high wear resistant layout that allows for the utilisation of the full width of the roll table. Combirolls are provided with a maintenance free clamping system that does not need to be retightened. Additionally, the roll shaft can be equipped different times with new roll rings.