Industry News

-

How hard is it to scratch tungsten carbide?

Tungsten carbide is extremely hard and is one of the hardest materials known. It’s even harder than titanium and steel. Tungsten carbide dies has a Mohs hardness of 8.5 to 9, second only to diamond, which has a hardness of 10. Therefore, it is difficult to scratch or damage tungsten carbide...Read more -

What are the disadvantages of tungsten carbide?

Tungsten carbide dies has several disadvantages, including: Brittleness: Tungsten carbide cold heading dies is brittle, which means it is prone to cracking or breaking under certain conditions. Limited Toughness: While tungsten carbide hot forging dies is very hard and wear-resistant, it has li...Read more -

What affects the service life of cemented carbide molds?

To improve the life of the mold, corresponding measures must be taken to improve these conditions. elarates on the main factors affecting the service life of the mold. 1. The impact of cemented carbide mold materials on mold life is a comprehensive reflection of the mold material type, chemical...Read more -

Who is the largest producer of tungsten carbide in the world?

Amongst the largest tungsten producing countries, China is the undisputed titan, as its annual tungsten production accounts for 84% of the world’s supply. Tungsten carbide cold heading dies is commonly used in the production of cutting tools such as drills, end mills and indexable inserts, ...Read more -

What are tungsten carbide dies for?

Tungsten carbide cold heading dies are specifically designed for use in the cold heading process, which involves forming a metal blank into the desired shape or profile at room temperature. carbide Cold forging is often used to make fasteners such as bolts, screws and rivets. Tungsten carbide mo...Read more -

Why is tungsten carbide so hard?

Tungsten carbide roller is known for its exceptional hardness due to a combination of factors. Firstly, tungsten itself is a very hard metal, with a high melting point and excellent strength. Secondly, when tungsten is combined with carbon atoms to form tungsten carbide, the resulting compound ex...Read more -

Application of tungsten carbide roller in deformed steel bar

The tungsten Carbide roller are widely used in deformed steel bar ,deformed steel bar is a processed steel used for applications such as making threads and fasteners. Carbide rollers play a very important role in the deformed steel bar processing process. First of all, Tungsten carbide ring roll...Read more -

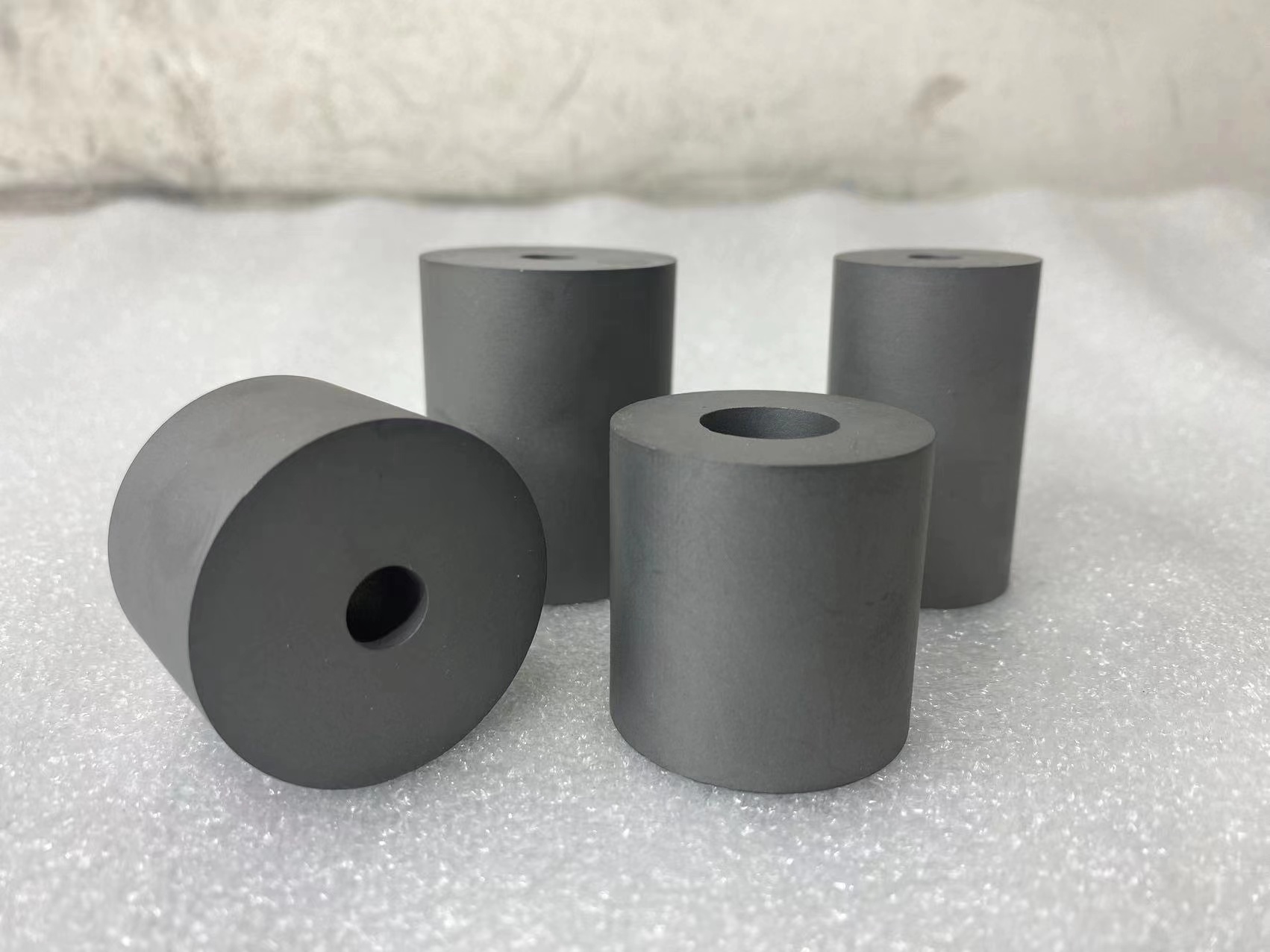

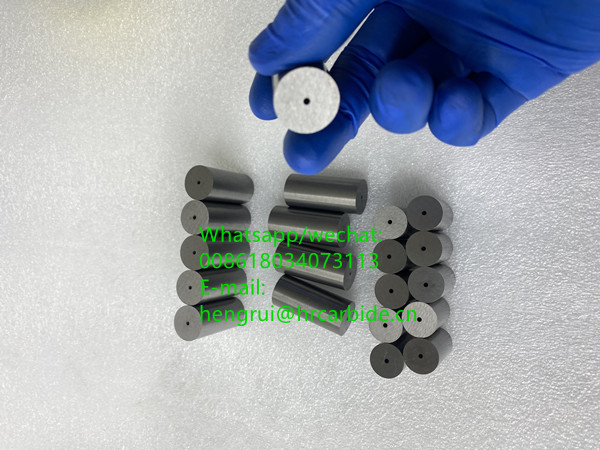

HengRui carbide Tungsten Carbide Pallets with clean ground surface

Tungsten Carbide pallets is an initial state of cemented carbide processing. When the cemented carbide blank is new, it generally means that the initial processing process has been completed and the conditions for further processing and forming are met. In the process of cemented carbide process...Read more -

How hardness tungsten carbide pallets is best for producing bolts, nuts and screws

Under normal circumstances, the hardness of tungsten carbide pallets used in the production of bolts, nuts and screws should be between HRA81.5-83. Carbide is usually made of tungsten-cobalt alloy and has the characteristics of high hardness, high wear resistance and high strength. Choosing the a...Read more -

High quality carbide roll, improve rolling efficiency and product quality

Tungsten Carbide roller promotional copy: High quality and wear-resistant, long roller life Our carbide ring rollers are manufactured from high-quality carbide materials and have excellent wear resistance. They can operate in high temperature and high pressure working environments for a long ti...Read more -

HIP sintering technology is used to ensure the quality of Tungsten carbide Pallets

Hot Isostatic Pressing (HIP) sintering technology is a common processing method for tungsten carbide pallets . HIP sintering technology is often used to increase the density, strength and wear resistance of GT55 tungsten carbide pellets In the HIPsintering process, the tungsten carbide di...Read more -

Welcome friends from all over the world to visit our carbide mold factory

Thank you very much for inviting friends from all over the world to visit our tungsten carbide mold factory. We will wholeheartedly welcome them and demonstrate our manufacturing processes and technologies. In our tungsten carbide dies factory, we have advanced equipment and a professional team ...Read more