Tungsten carbide dies has several disadvantages, including: Brittleness: Tungsten carbide cold heading dies is brittle, which means it is prone to cracking or breaking under certain conditions. Limited Toughness: While tungsten carbide hot forging dies is very hard and wear-resistant, it has limited toughness, making it more susceptible to chipping and breaking. Difficult to Form: Tungsten carbide dies is difficult to form or machine, which increases manufacturing costs. High cost: Tungsten carbide cold heading dies is relatively expensive compared to other materials, which may affect its suitability for certain applications. Susceptible to chemical attack: Tungsten carbide is susceptible to chemical attack under certain conditions, which can limit its use in certain environments. It is important to consider these disadvantages when selecting tungsten carbide for a specific application.

Carbide usually refers to a compound composed of carbon and metal, such as calcium carbide or tantalum carbide. Tungsten carbide, on the other hand, specifically refers to a compound of tungsten and carbon, often alloyed with small amounts of other elements, such as cobalt, to form a very hard, wear-resistant material tungsten carbide cold heading dies commonly used in cutting tools, industrial machinery, and other applications. Tungsten carbide is highly appreciated for its hardness and wear resistance, making it a popular choice in many industrial applications.

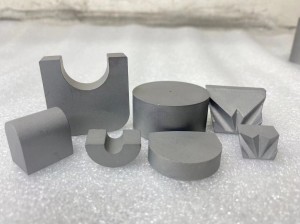

Tungsten carbide, also known as hard metal, is a compound made of tungsten and carbon. It is known for its exceptional hardness, wear resistance and high strength. Tungsten carbide is commonly used in a wide range of industrial applications, including cutting tools, drill bits, saw blades and other tools that require high wear resistance and durability. Due to its properties, tungsten carbide dies is valued for its ability to withstand high temperatures and heavy use, making it a popular material in a variety of manufacturing and engineering processes.

https://www.ihrcarbide.com/cold-heading-mold-for-stainless-steel-screws-product/

Post time: Dec-18-2023