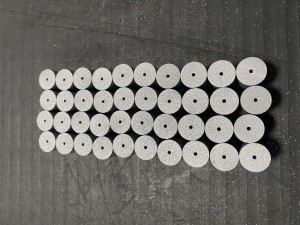

Tungsten carbide cold heading dies are specifically designed for use in the cold heading process, which involves forming a metal blank into the desired shape or profile at room temperature. carbide Cold forging is often used to make fasteners such as bolts, screws and rivets. Tungsten carbide molds are the first choice for cold heading applications due to their exceptional hardness, wear resistance, and ability to maintain precise dimensional tolerances even under high-pressure conditions. These properties make tungsten carbide cold heading molds ideal for producing high-quality, uniform parts.

Tungsten carbide molds are used to shape or form materials such as metals, plastics, or other substances. They are commonly used in industries such as metalworking, wire drawing and manufacturing to produce precise and uniform shapes or profiles. Tungsten carbide is known for its hardness and wear resistance, making it ideal for applications where durability and precision are critical.

Tungsten carbide cold heading molds have many advantages, such as high hardness, wear resistance, and the ability to maintain shape at high temperatures. However, they also have some disadvantages, including: Brittleness: Tungsten carbide is relatively brittle and can chip or crack easily, especially when subjected to strong impacts or sudden changes in temperature. High cost: Tungsten carbide is an expensive material, which results in higher production costs for cold heading molds compared to other materials. Machining Difficulty: Tungsten carbide cold heading dies is very hard, which makes machining and forming challenging. Manufacturing tungsten carbide cold heading molds requires specialized equipment and expertise, which increases production costs and lead times. Coating application: Tungsten carbide cold heading molds may require special coatings to improve performance, which increases manufacturing complexity and cost. Despite these disadvantages, tungsten carbide screw dies cold heading molds are widely used in the production of fasteners and other metal parts due to their excellent hardness and wear resistance, which can extend mold life and increase productivity.

Post time: Dec-06-2023