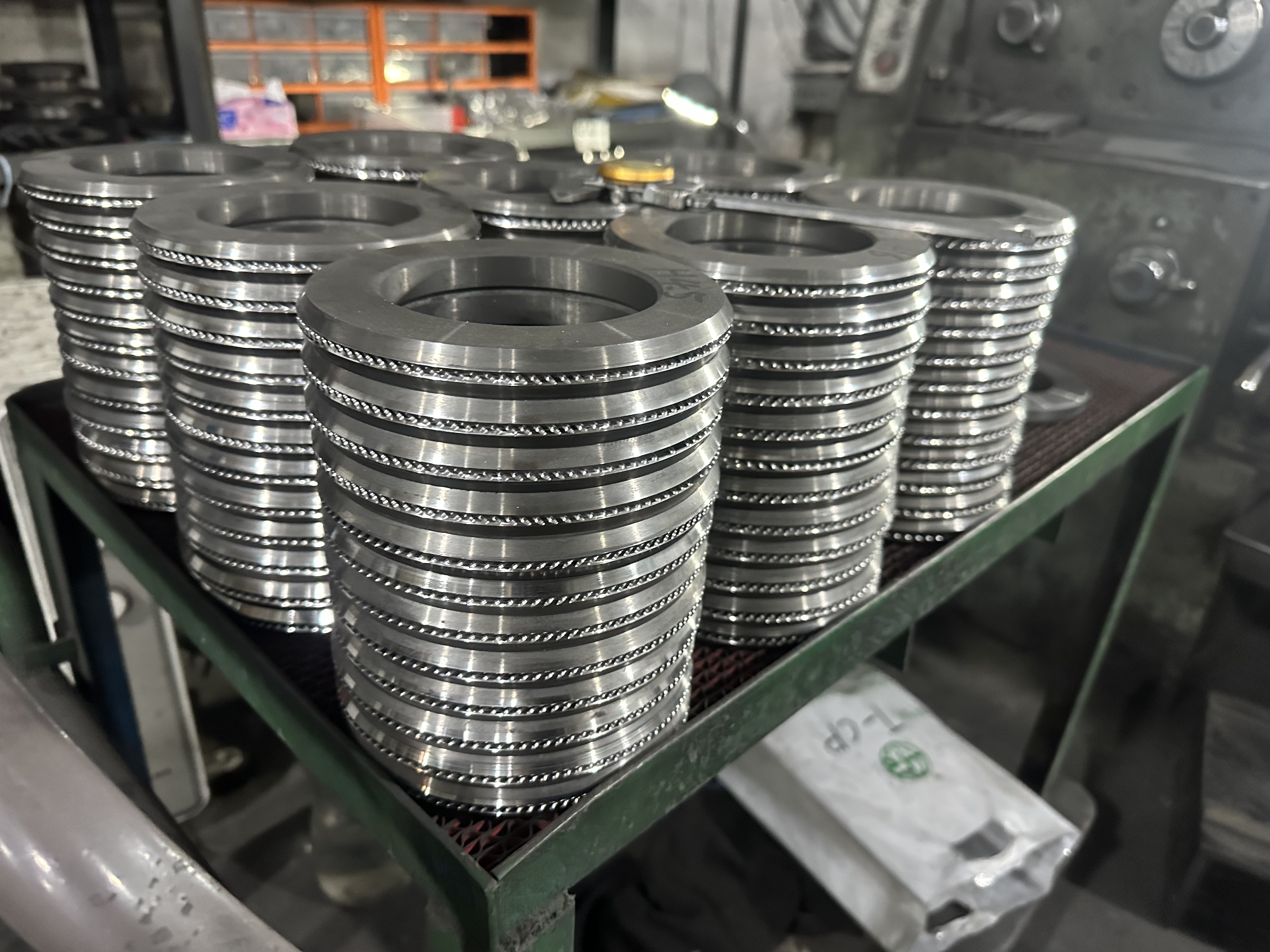

Carbide roller rings (also called tungsten carbide roller rings) have superior performance, stable quality, high product processing precision, good wear resistance and high impact resistance. Alloy rollers are available in two types: integral type and combined type. .

Carbide rolls have high hardness, and their hardness changes very little with temperature. The hardness at 700°C is 4 times that of high-speed steel; the elastic modulus, compressive strength, flexural strength, and thermal conductivity are also all the same. More than 1 times higher than tool steel. Due to the high thermal conductivity of the cemented carbide roll, the heat dissipation effect is good, so that the surface of the roll is at high temperature for a short time, so the high-temperature reaction time between the roll and harmful impurities in the cooling water is short. Therefore, carbide rolls are more resistant to corrosion and thermal fatigue than tool steel rolls. Product advantages:

1. Made of YG15 cemented carbide, which has strong hardness and high bending strength

2. The product has stable performance and high accuracy.

Made from raw materials to ensure the best performance of the product

3.100% alloy is pressure sintered

4 Industry-leading after-sales guarantee, 100% return and exchange of defective products

Post time: Jan-23-2024