Best Tungsten Carbide Cold Heading Dies Manufacturer in China – HeBei HengRui

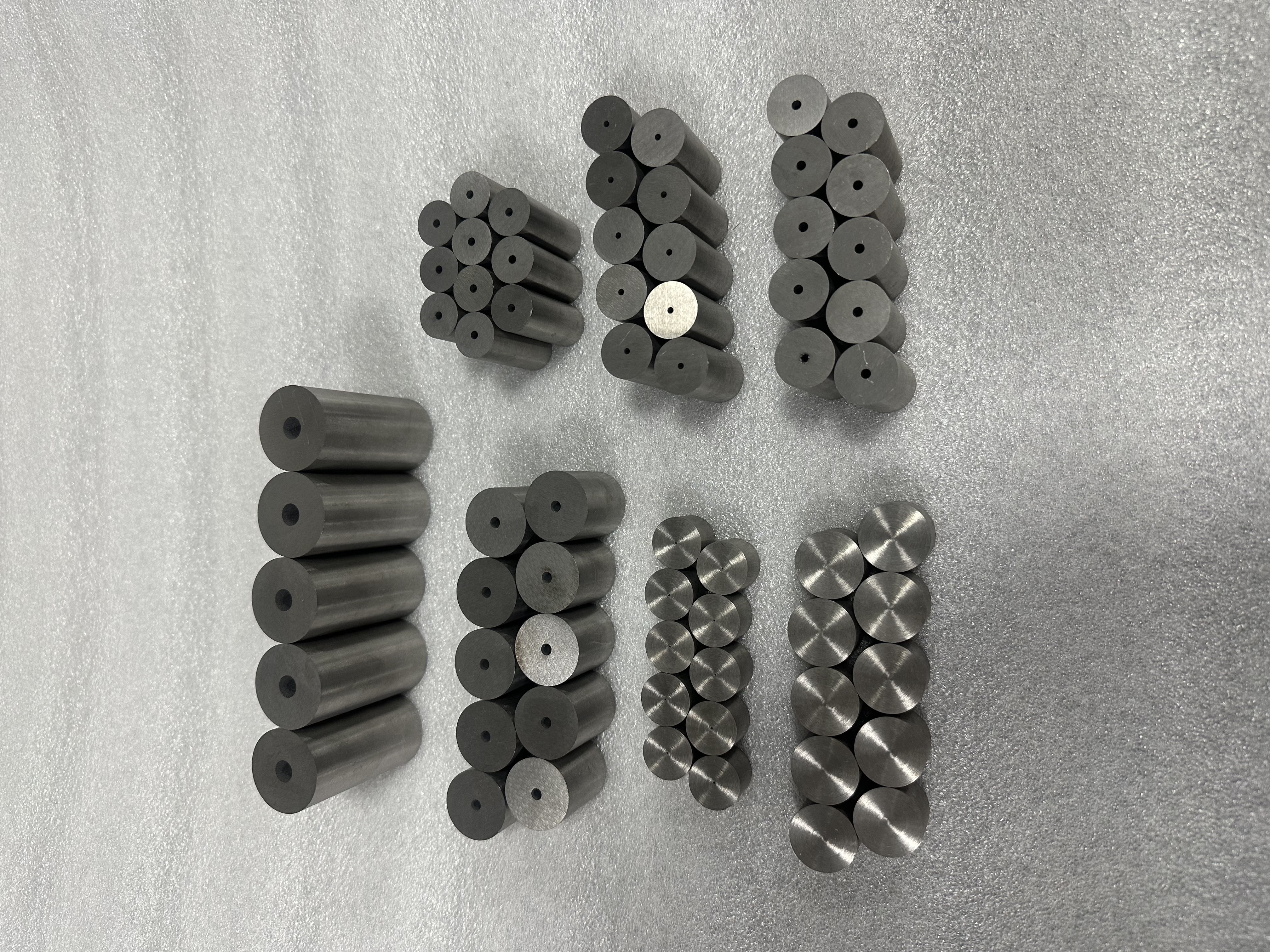

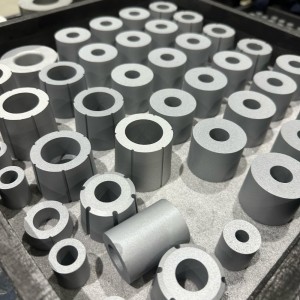

Tungsten carbide cold heading dies has high impact resistance, high toughness, good wear resistance, and quality consistency. The are different grade with different properties and applications, which have been proved to be ideal in making non-ferrous metal, ferrous metal and their alloys. You are encouraged to use our professional carbide grades for cold heading &punching die nibs, under our engineer’s professional suggestion.

1. 100% virgin raw materials.

2. Various kinds of grades are available.

3. ISO quality control system.

4. Precision Ground and high polishing process

5. High wear resistance, high hardness and high impact toughness

6. 7x24 online support.

Cold heading dies also called tungsten carbide punching, cold forming dies, or heading dies. It is compressed by powder metallurgy, with high hardness, high-strength cemented carbide dies, as an important working component of cold heading machine, completes punching, bending, stretching, etc., and is widely used in the field of production and processing.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Dies for fasteners are important working components for fasteners industries to produce screws, bolts, nuts, etc. All types of cold heading die, header punches and thread rolling dies are offered for production in accordance with customer drawings from high-quality tungsten carbides and steel, with the use of coatings on working surfaces.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 7days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% before delivery. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.