Strong Tungsten Carbide Cold Heading Die for Bolt Cold Heading Forging Die

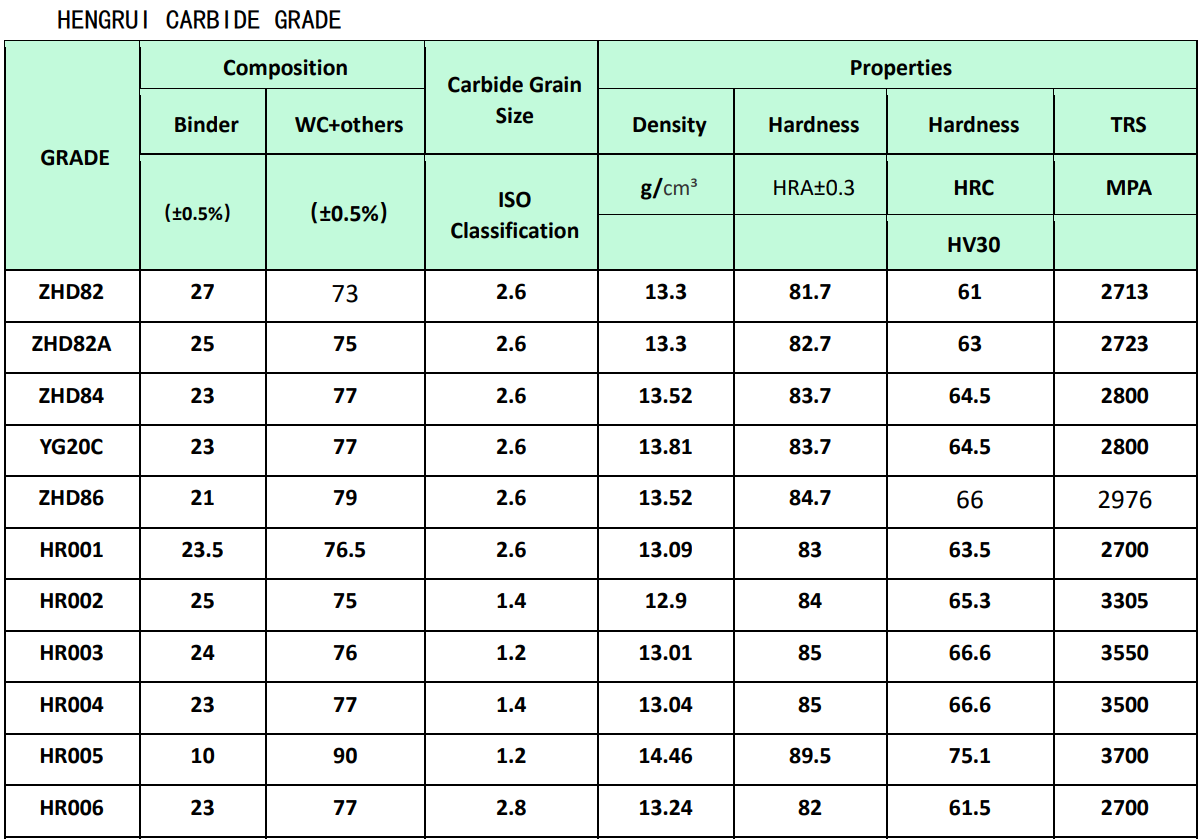

Our factory has complete processing equipment and strong production technology. For example, we have long-term cooperation with some domestic R&D units to develop and produce new products in the field of cemented carbide. We have helped the R&D units overcome and solve many technical problems and gained the technical trust and recognition of the R&D units.

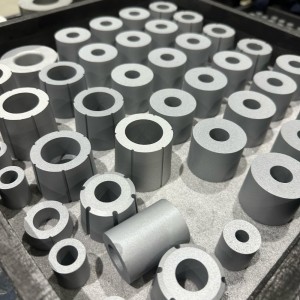

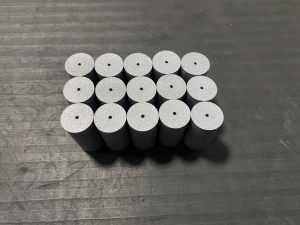

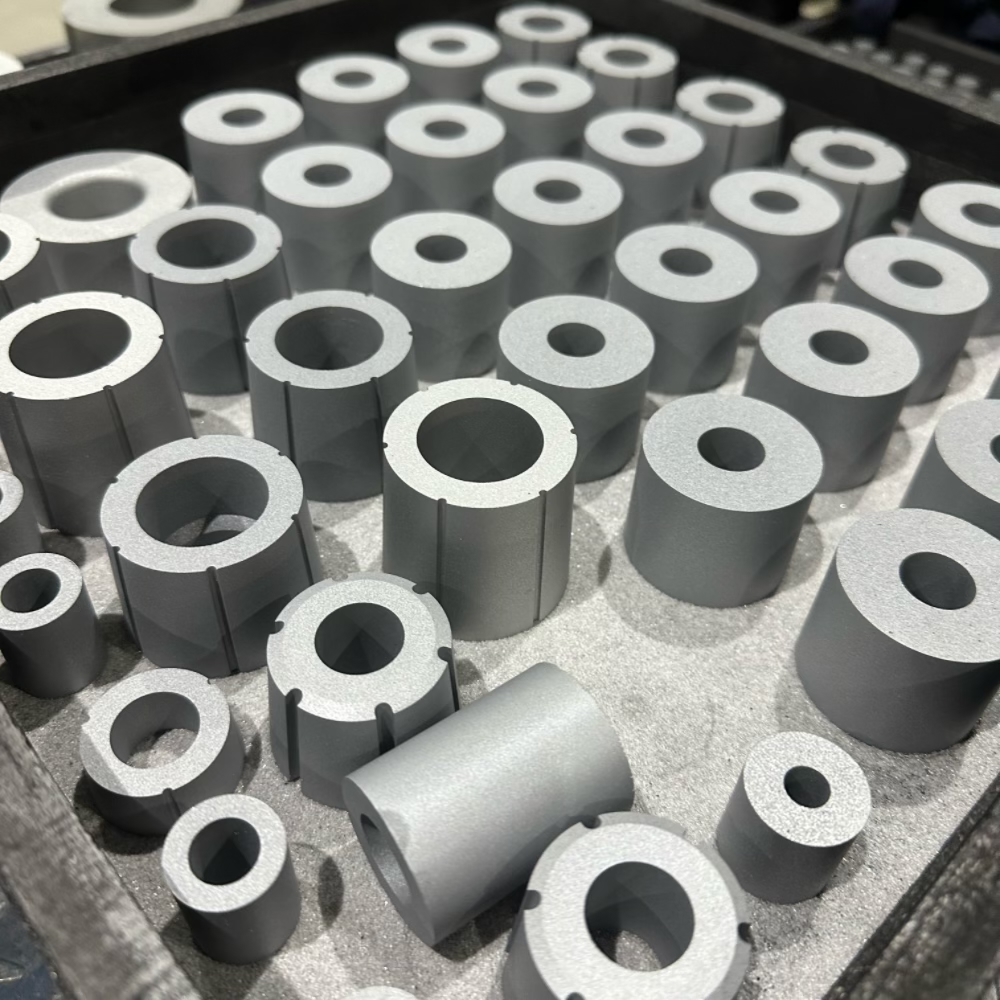

The factory has excellent processing and testing methods, and can provide various high-quality products and technical services to domestic and foreign users in a timely manner, and can design, process and produce various cemented carbide products and molds according to the different needs of users. More users at home and abroad are welcome to establish business contacts and technical cooperation with Renqiu Hengrui Cemented Carbide Co., Ltd.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

The thermal processing quality of the mold has a great impact on the performance and service life of the mold. It can be seen from the analysis and statistics of the causes of mold failure that mold failure "accidents" caused by improper heat treatment account for more than 40%. The quenching deformation and cracking of the working parts of the mold and the early fracture during use are all related to the thermal processing process of the mold. Forging process, preparatory heat treatment, quenching and tempering, stress relief annealing, machined surface quality, etc. are all important factors that affect the service life of the mold.

We provide processing with supplied materials, customized services, customization of drawings, and can also design molds suitable for your use based on your cold heading machine.

We have 5 HIP sintering furnaces with a daily output of 1.2 tons. Delivery takes 3 to 10 days after payment.