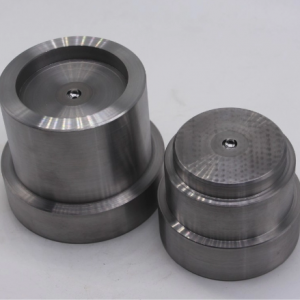

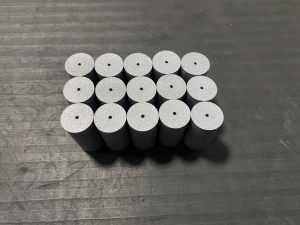

Round Tungsten Carbide Stamping Forming Die For Screw Making

1. Chinese factory specialized in processing and production, ISO certification.

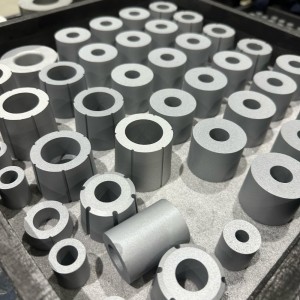

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

High Hardness and High Wear Reaistance

Hengrui Cemented Carbide Are Harder and Better Wear Resistance,does Not Wear out Too Much,because of Long Use.

Does Not Strain the Surface of the Machined Part

The Products Are Smooth and Smooth, and the Role of Nanometer Diamond Coatings, gives the Products an Excellent Surface Finish and Low Friction, will Not Damage the Surface of the Part.

Corrosion Resistance

Good Oxidation Resistance, generally, it is Very Resistant to Atmospheric, acid, and Alkali Corrosion, not Easy to Oxidize, and Can Maintain the Integrity of the Products.

Wide Range of Applications

Widely Used in Various Industries for Drawing, forming and Shaping Dies. such As Stainless Steel, tableware, metal Utensils, hardware Accessories Etcs.

1:High Quality for Injection Mold

2: Reasonable price for Injection Mold

3:On time delivery for Injection Mold

4:Good after-sale service for Injection Mold from China Supplier

5:Strict quality control

6:All the mold are automatic

We will offer you: 1: In-time response on letters,telephone calls or fax

2:In-time supply the quotation and mold desgns

3:In-time communication on the technical points

4:In-time sending pictures for the mold machining progress and mold finishing schedule

5:In-time mold test and sample delivery

6: In-time mold delivery from alibaba China Supplier.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.