HengRui VA80 VA90 Tungsten Carbide Cold Heading Pellets

Cemented carbide is known as the "teeth" of industry. Since its advent in 1923, it has a history of more than 80 years. In 1947, the world's cemented carbide production was only 1,600t, but by 19067, the world's cemented carbide production had reached 11,000t.

By 1981, world cemented carbide production had reached 25,000 tons. Today's world cemented carbide production has exceeded 40,000 tons.

China's cemented carbide production is about 20,000 to 30,000 tons, and the growth in world cemented carbide production mainly comes from China. While China's growth is basically all in mid- and low-end products, the production of high value-added products is still firmly in the hands of developed countries.

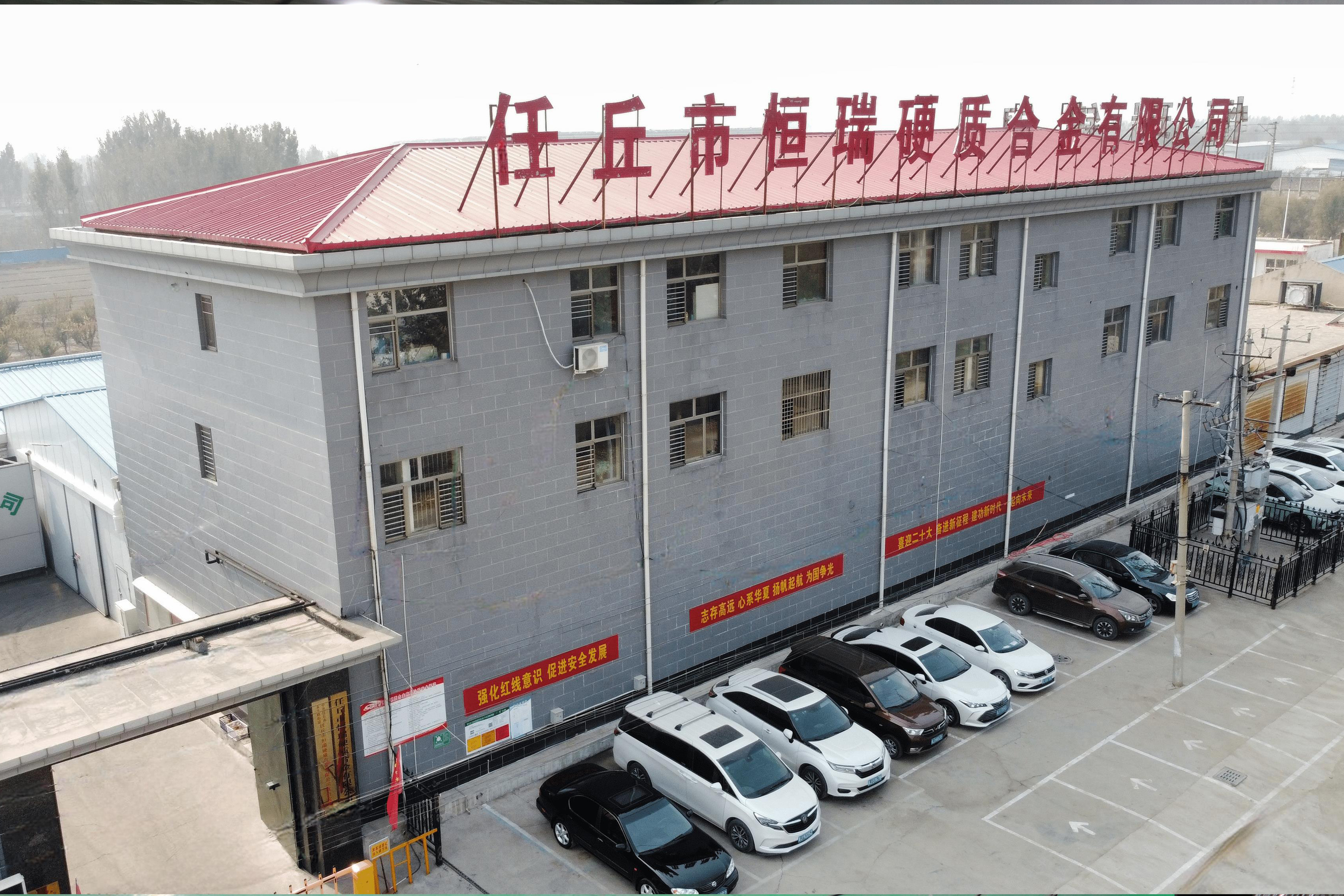

Renqiu Hengrui Precision Cold Forging Mold, a team of 100 people, has been focusing on precision molds for the automotive, medical, new energy and other industries. It focuses on the research and development, design and customized production of precision tungsten steel screw molds and bolt molds. Carbide cold heading Heading dies provide fastener manufacturers with products of stable quality.

Some of the wear products that we manufacture from tungsten carbide are:

1. Crusher tips and jaws

2. Conveyor scraper blade tips

3. Shot blast nozzles,lance tips,wheel blades

4. Tipped static and rotary recycling shredding blades

5. Impact and wear plates

6. Faced bar hammers

RenQiu HengRui Tungsten Carbide can make as per your request, once detailed application and drawing can be provided. High wear resistance and durable performance can be reached with sufficient communication.

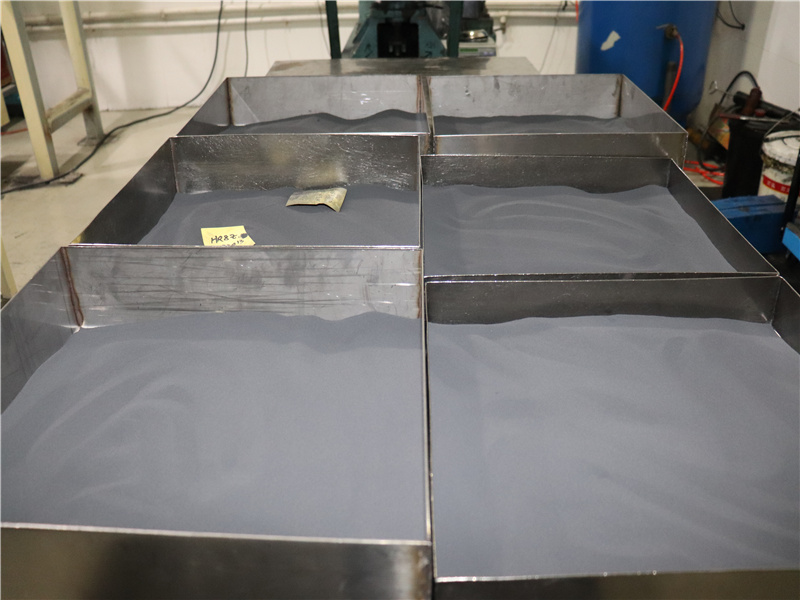

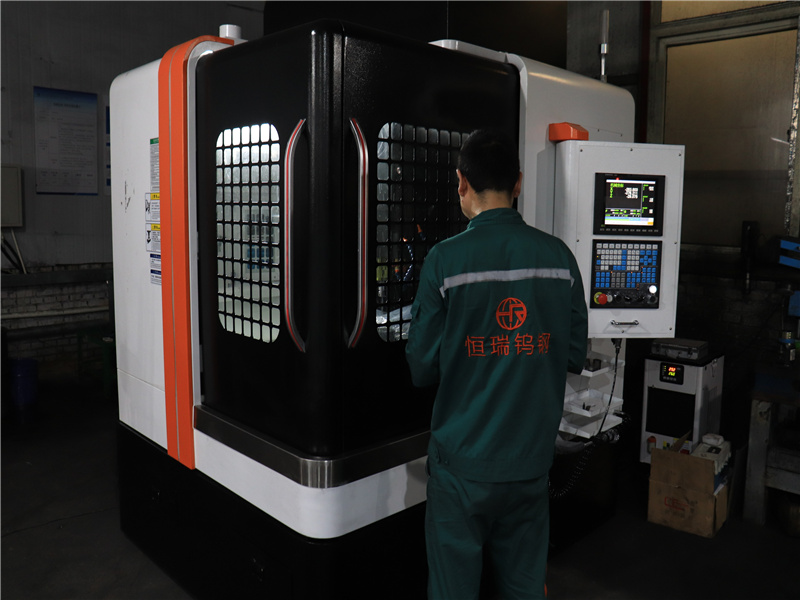

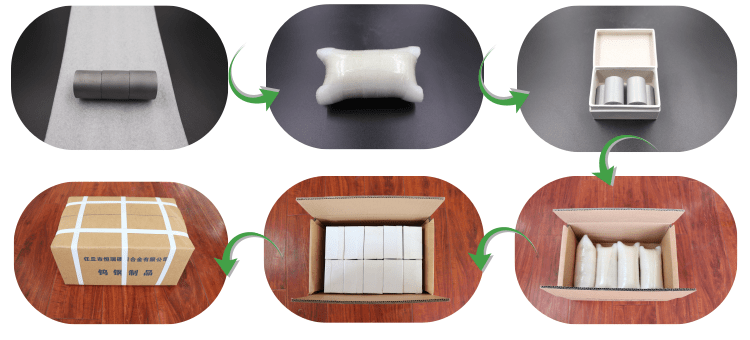

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

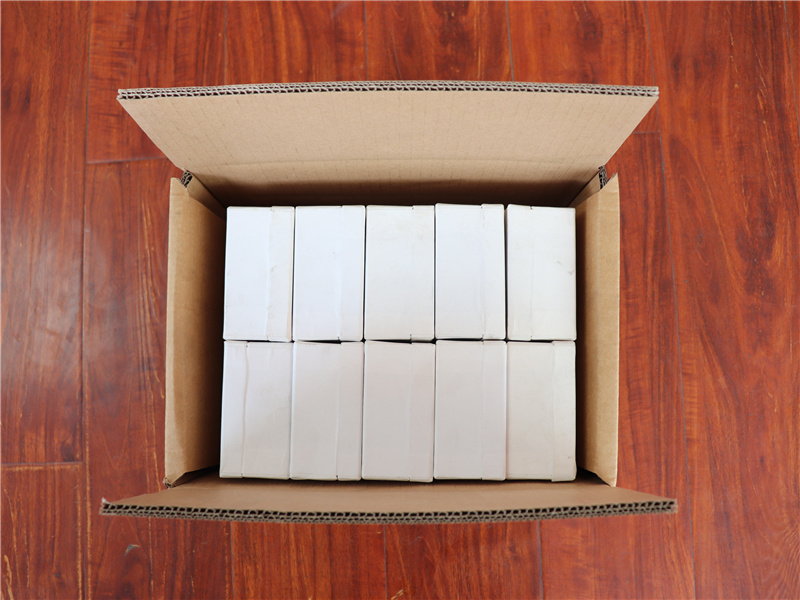

We can deliver the goods within 7 to 10 days after receiving the deposit, or within 3 to 5 days according to your requirements. Our production capacity is 2 tons per day.

Q1: Why did you choose us?

A1: We are a direct manufacturer and can provide more stable quality.

Q2: Do you provide free samples?

A2: Yes, we can provide free samples, but the sample cannot exceed 1kg, and you are responsible for the shipping cost.

Q3: What is your minimum order requirement?

A3: 1kg.

Q4: What is the delivery time of your products?

We have a large stock of cold heading dies and if you need this size we can ship it same day.

Q5: What kinds of production do you supply?

Our entity factory directly supplies tungsten carbide cold heading dies,rollers,bushing,wire drawing dies,and wear resistant parts.We not only offer international grades, but we have also developed hundreds of our own grades for use in different scenarios.