Surface ground carbide cold heading die blanks

1. We produce products with 100% virgin materials

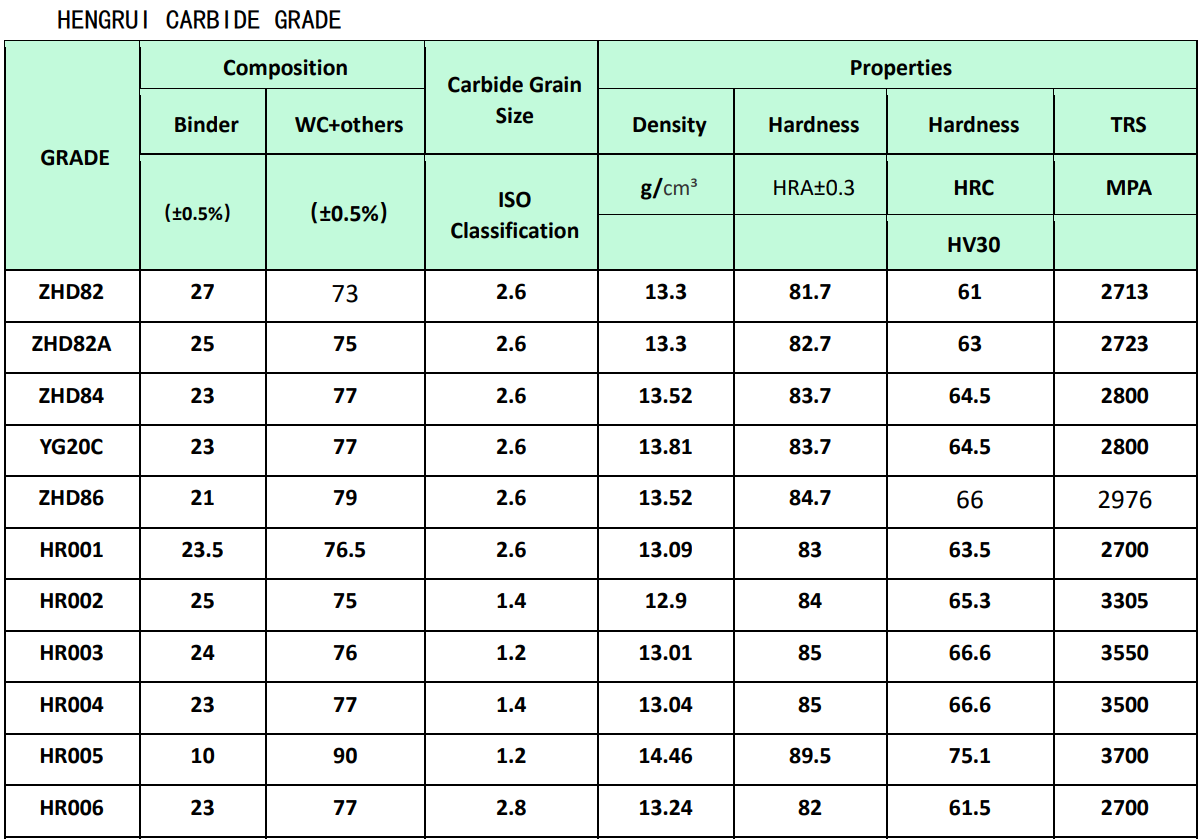

2. We will choose different levels according to your different needs such as production technology, usage scenarios and production products.

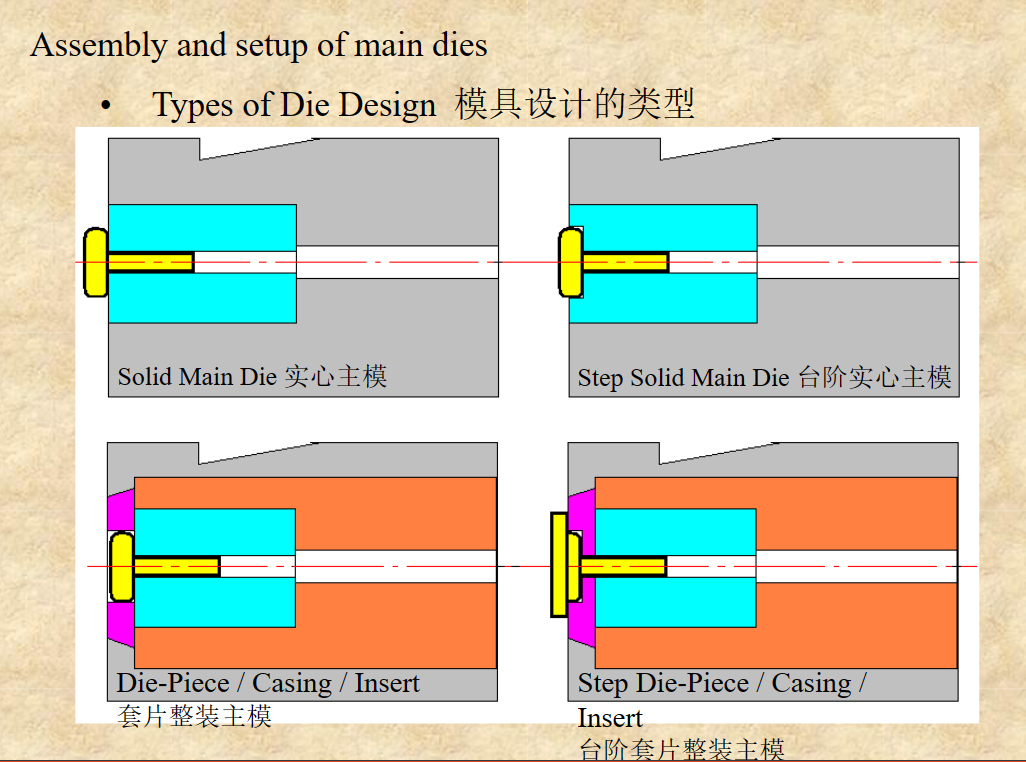

3. We can not only provide tungsten carbide blanks, but also grinding surfaces and finished cold heading molds.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. Cold heading is carried out under normal temperature conditions. Cold heading can improve the mechanical properties of metal parts.

2. Cold heading forging process can improve material yield. It is a pressure processing method based on plastic deformation, which can achieve less or no cutting processing. Generally, the material utilization rate is above 85%, and can reach as high as above 99%.

3. Can improve production efficiency. The time and process of deforming metal products are relatively short, especially when parts are processed on multi-station forming machines...

4. The cold heading and forging process can improve the surface roughness of the product and ensure product accuracy.

1. It has high hardness and strength to ensure that the mold is resistant to pressure, wear, deformation and adhesion during work;

2. It has high wear resistance to ensure that the shape and size tolerances of the mold change within a certain range during long-term operation and will not fail due to excessive wear;

3. Have sufficient toughness to prevent the mold from brittle fracture under impact load;

4. The heat treatment deformation is small to ensure that the mold will not be scrapped due to excessive deformation during heat treatment;

5. It has high thermal hardness to ensure that the mold will not soften due to temperature rise during high-speed stamping or heavy-load stamping processes.

1. Contact us, our business manager is online 24 hours a day.

2. If we do not respond to your message in time, please send your drawing request to our email.

3. We will give you a quotation within 24 hours after receiving your order.

Delivery takes 3~10 days after receiving deposit