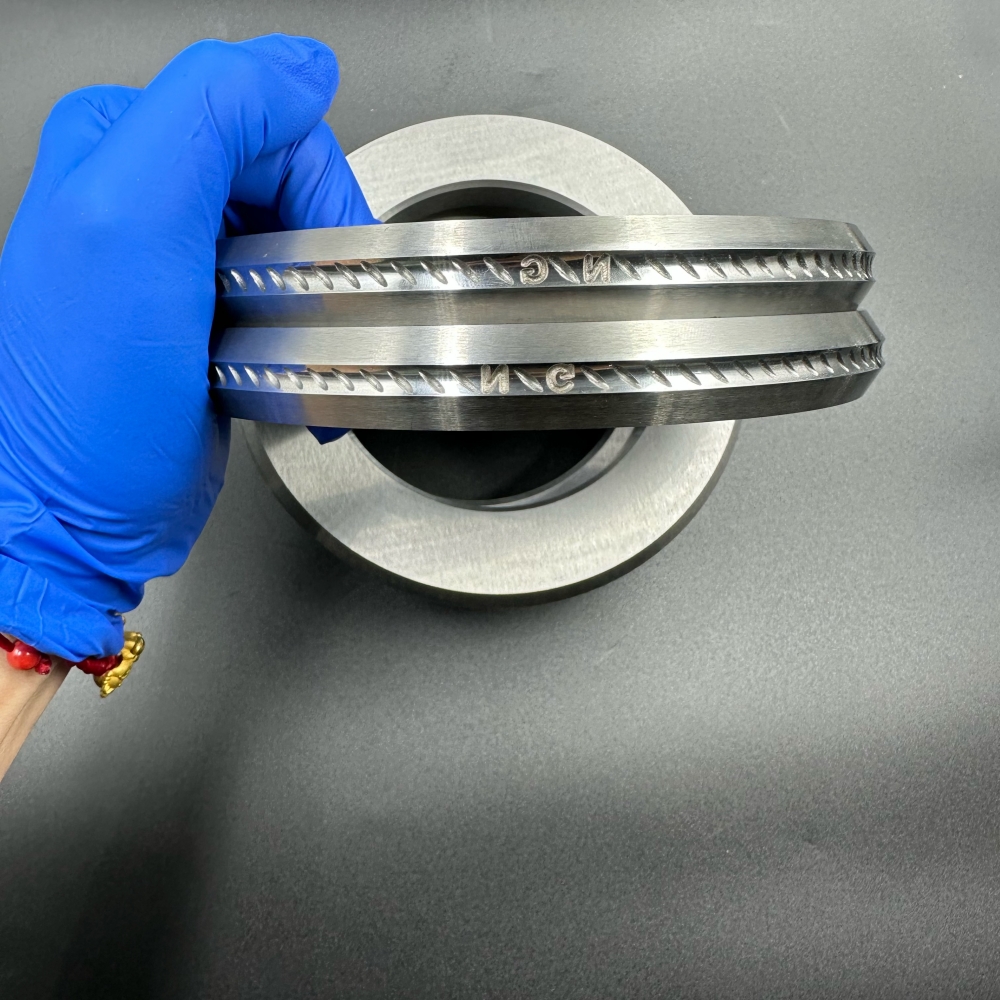

Customized yg15 Cemented Carbide Roller Ring Tungsten carbide Roll TC Roll for Steel Wire

Tungsten carbide roller ring High hardness and good wear resistance:hardness at room temperature can reach HRA78-89,good red hardness under high temperature,600°C over high-speed steel,1000°C over the room temperature of carbon steel.

High mechanical strength:The compressive strengthof up to 60000MN/m2,900°C,the bending strength can still above 1000MN/m2.

Some of the wear products that we manufacture from tungsten carbide roller are:

1. PR ROLLER

2. PO ROLLER

3. FO ROLLER

4. RO ROLLER

5. CA ROLLER

RenQiu HengRui Tungsten Carbide can make as per your request, once detailed application and drawing can be provided. High wear resistance and durable performance can be reached with sufficient communication.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Tungsten carbide roller has been used in various fields of metal plastic processing. From non-ferrous metals to steel, from hot-rolled wire rod, pipe to cold

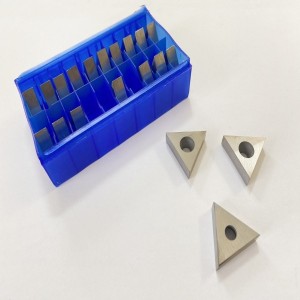

1. Use 100% tungsten carbide raw material.

2. Stable chemical properties

3. Excellent performance and good wear/corrosion resistance

4. HIP sintering,good compactness

5. Blanks,high machining accuracy/precision

6. OEM customized sizes available

7. Factory’s offer

8. Strict products quality inspection

we could manufacture tungsten carbide cold rolls with a complete range of sizes, HIP sintering, reliable quality, fast delivery.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 10~15days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.