Industry News

-

The grade of tungsten carbide dies

The grade of cemented carbide mold mainly refers to the grade of tungsten-cobalt cemented carbide mold. 1. YG6: The WC content is 94%, the particle size is about 1.2um, and it is often used in the production of cutting tools, molds and other tools. 2. YG8: The WC content is 92%, the particle si...Read more -

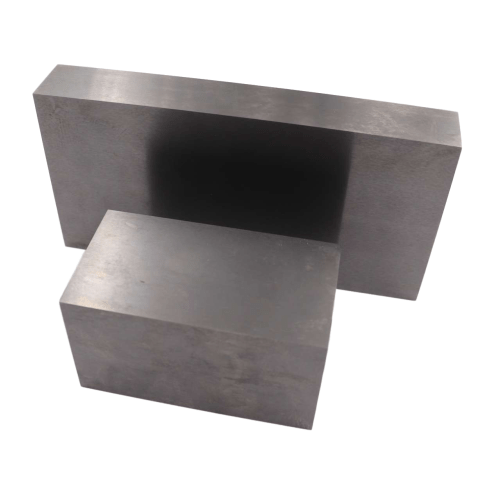

Strong and durable to help production – tungsten carbide tooling

1. Tungsten carbide mold, solid texture, wear resistance and compression resistance, long life and durability. 2. Using advanced technology and fine manufacturing to ensure high precision and strong durability, it can meet the needs of various high-precision molds. 3. Using cemented carbide molds...Read more -

Advantages of Tungsten carbide raw Material

The advantages of tungsten steel raw materials include: 1. High hardness: The hardness of tungsten steel is very high, which can reach 80-90HRC. This means it can withstand a lot of mechanical wear and the high stresses of cutting. 2. Wear resistance: Due to the high hardness of tungsten ...Read more -

Is it technically difficult to produce cemented carbide?

The technical difficulty required to produce cemented carbide is relatively high, mainly in the following aspects: 1. The ratio and selection of raw materials are very critical. Different products require different formulas and raw materials. Manufacturers need to have a high level of technology ...Read more -

Application of Cemented Carbide Ball Valves

Cemented carbide ball valve is evolved from the traditional plug valve, its opening and closing member is a ball, through the ball around the stem axis to achieve the purpose of opening and closing. The working environment and conditions of the oil drilling industry are very harsh, usually in sa...Read more -

Characteristics of Cemented Carbide Wear Parts

Carbide wear-resistant parts are high-strength wear-resistant materials, and their characteristics mainly include the following points: 1. High hardness: The hardness of hard alloy wear-resistant parts can reach more than HRA80, which is much higher than that of ordinary steel. 2. Good wear resi...Read more -

Cemented carbide in life applications

Carbide has many applications in life, the following are some common applications: 1. Cutting tools: Cemented carbide has high hardness and wear resistance, so it is used to manufacture cutting tools such as knives, saw blades, and drill bits. 2. Mining tools: Cemented carbide can be used to manu...Read more -

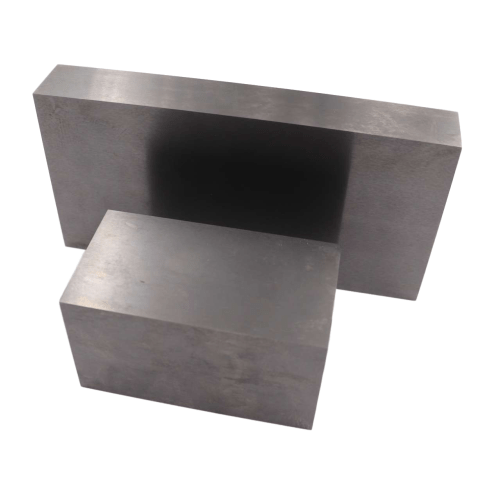

Characteristics of Cemented Carbide Tooling

Tungsten carbied plate has excellent hardness, high hardness, good wear resistance, high compressive strength, etc. The tungsten and cobalt content in tungsten carbide varies from application to application, and can be used in various drawing dies, stamping, blanking dies, wear and corrosion resi...Read more -

Maintenance of tungsten carbide

Tungsten carbide is a material with high hardness, high wear resistance and high corrosion resistance, so special maintenance measures are required to prolong its service life. The following are some common carbide maintenance methods: 1. Avoid excessive wear. Carbide is commonly used to make kni...Read more -

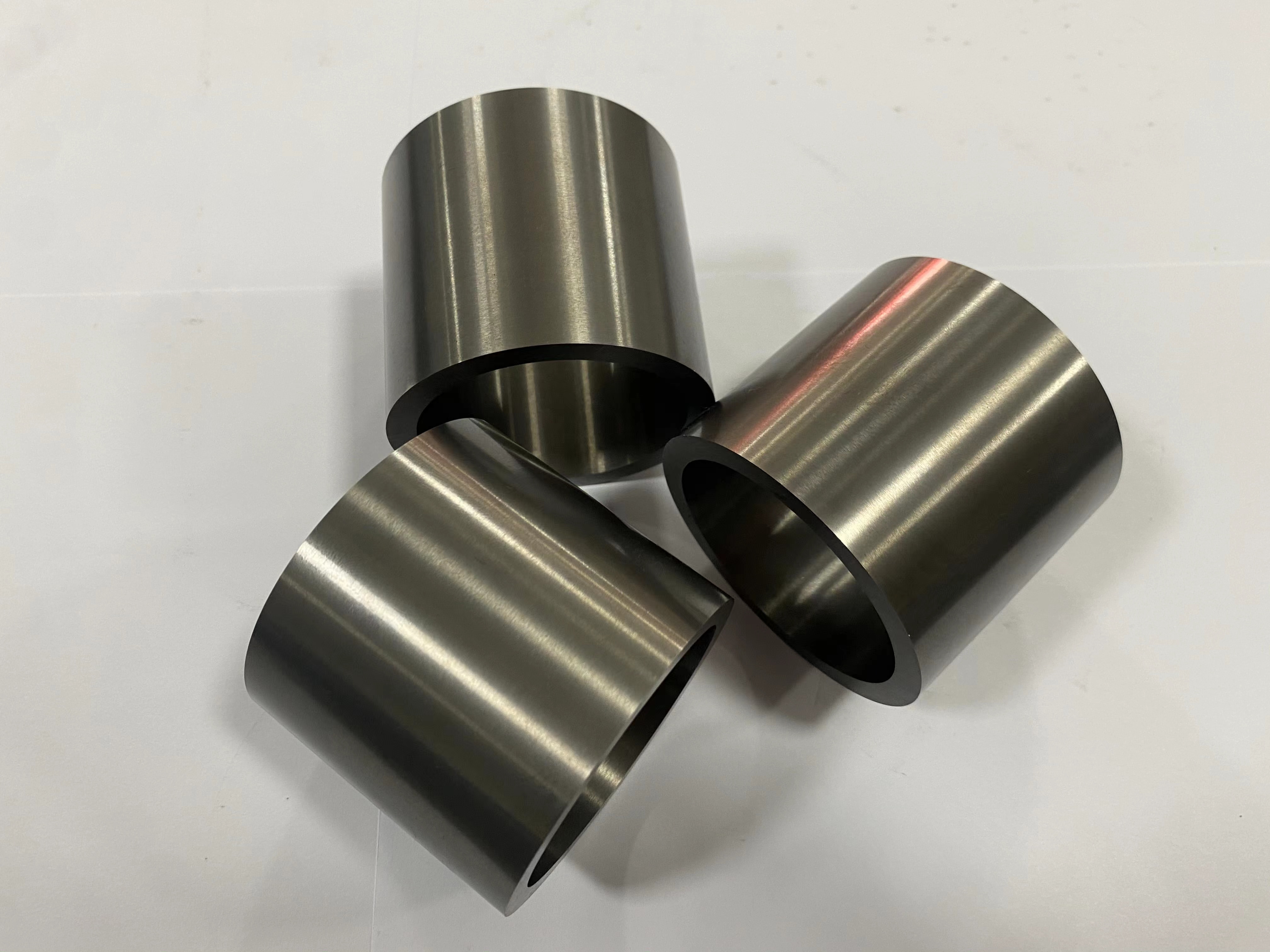

Possibilities of mold that can be produced with tungsten carbide

1. die-casting moulds: for the production of various complex and precise die-casting products; 2. injection moulds: for the production of a variety of complex-shaped plastic products; 3. stamping dies: for the production of various metal sheet parts; 4. extrusion dies: for the production of vari...Read more -

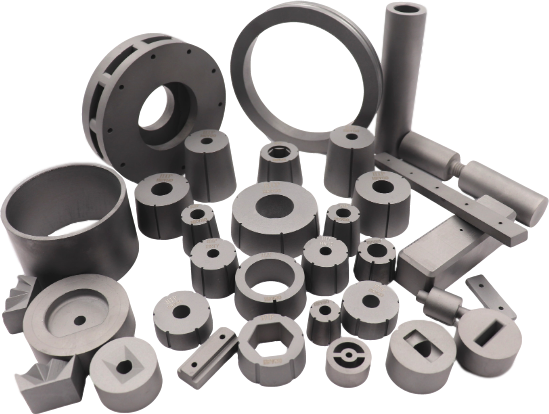

History of rolls

Roll variety and manufacturing process with the progress of metallurgical technology and the evolution of steel rolling equipment and continuous development. In the middle of the 18th century, Britain mastered the production technology of chilled cast iron rolls for rolling steel plates, and in t...Read more -

Main properties of cemented carbide rolls

The main properties of tungsten carbide to be considered in selecting tungsten carbide rolls are as follows: Resistance to thermal cracking Usually for rough rolls to strength, resistance to thermal cracking as the main requirements; small 20-roll mill working rolls weigh only about 100 grams, wh...Read more