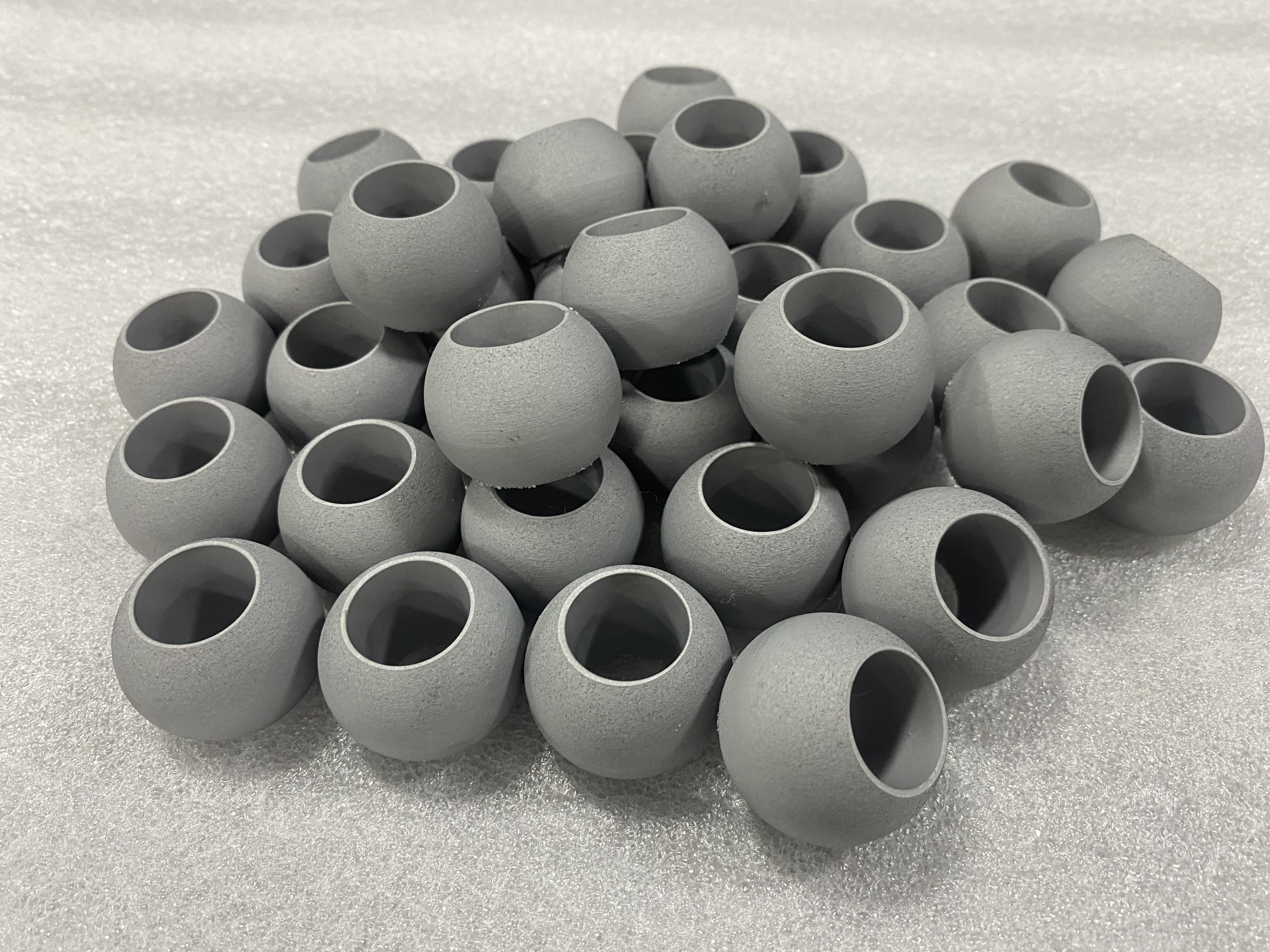

Cemented carbide ball valve is evolved from the traditional plug valve, its opening and closing member is a ball, through the ball around the stem axis to achieve the purpose of opening and closing. The working environment and conditions of the oil drilling industry are very harsh, usually in sandy wells, thick oil wells, high-pressure anti-sparse oil wells containing water, various gases, wax, sand and some other highly corrosive substances, the pumping pump needs to extract oil from hundreds or even thousands of meters of strata, which requires the valve ball and valve seat to have good sealing, wear and corrosion resistance. The carbide ball valves produced by Sidi are wear-resistant, corrosion-resistant and anti-acid and alkali, and are the balls used on valves and bearings and high-pressure vessels, with nano precision and 0.025 degree of finish. to meet the high requirements of oil drilling harsh environment for the required parts and equipment.

Cemented carbide ball valves have several outstanding performance characteristics as follows: 1、 Cemented carbide ball valves have the lowest theoretical flow resistance and reduce friction; 2, has excellent chemical stability and wear and corrosion resistance, can be in contact with most of the liquid and some corrosive media; 3、 Cemented carbide ball valve can still achieve complete sealing effect under high temperature and high pressure environment; 4, because the carbide ball valve as the opening and closing parts, less affected by friction, can achieve rapid opening and closing, and the operation of less impact, and, the spherical closing parts can withstand the high pressure difference exists when closed, and also can achieve automatic positioning; 5, Cemented carbide ball valve has two-way sealing, making the work more stable and reliable.

Post time: May-25-2023