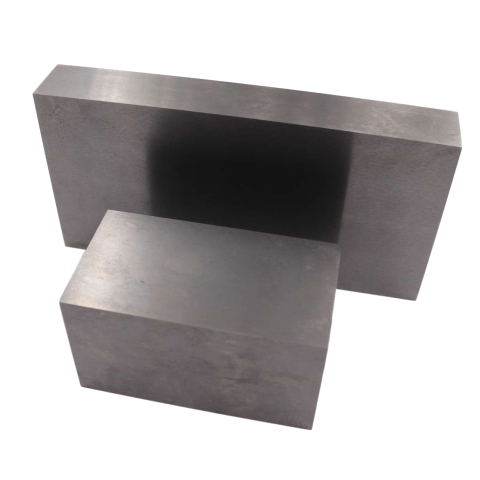

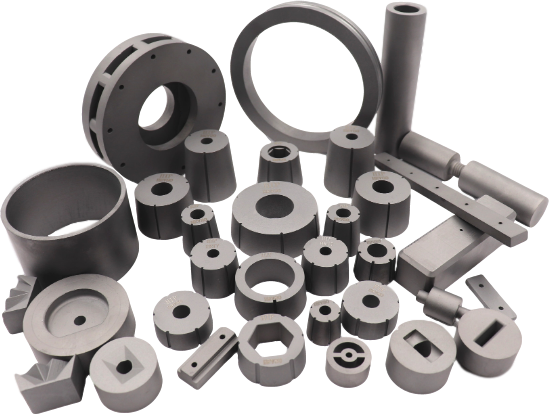

The grade of cemented carbide mold mainly refers to the grade of tungsten-cobalt cemented carbide mold.

1. YG6: The WC content is 94%, the particle size is about 1.2um, and it is often used in the production of cutting tools, molds and other tools.

2. YG8: The WC content is 92%, the particle size is about 1.5um, and it is often used in the production of drill bits, milling cutters, cutting tools and other tools.

3. YG10: The WC content is 90%, and the particle size is about 1.7um. It is often used in the production of nozzles for soldering, thermal spraying and other processes.

4. YG15: The WC content is 85%, and the particle size is about 2.5um. It is usually used to produce high-load tools such as rolls, cold molds, and hot molds.

5. YG20: The WC content is 80%, and the particle size is about 3.0um. It is often used in the production of mining machines, rail vehicles and other tools.

6. YG11: It is a hard alloy mold with general hardness, which is mainly used to produce some metal parts with medium hardness.

Post time: May-28-2023