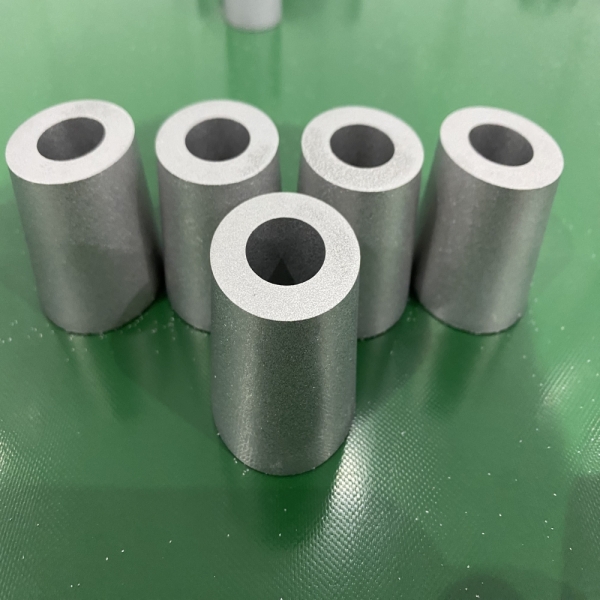

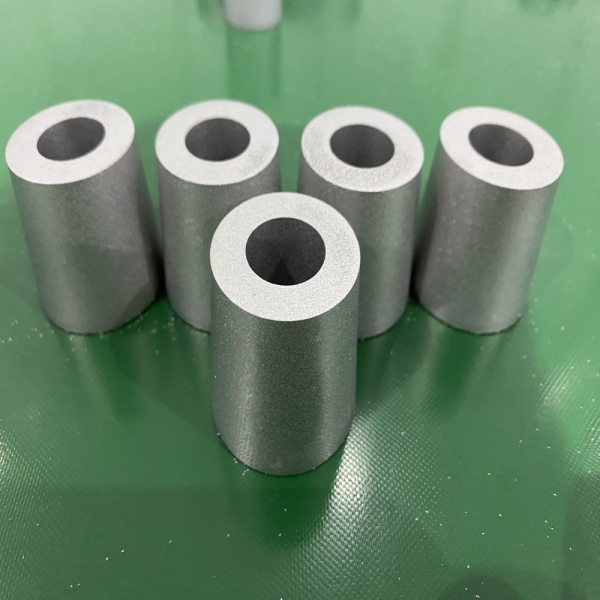

HR carbide Tungsten Nuts Bolts and Fasteners china Manufacturer Supplier

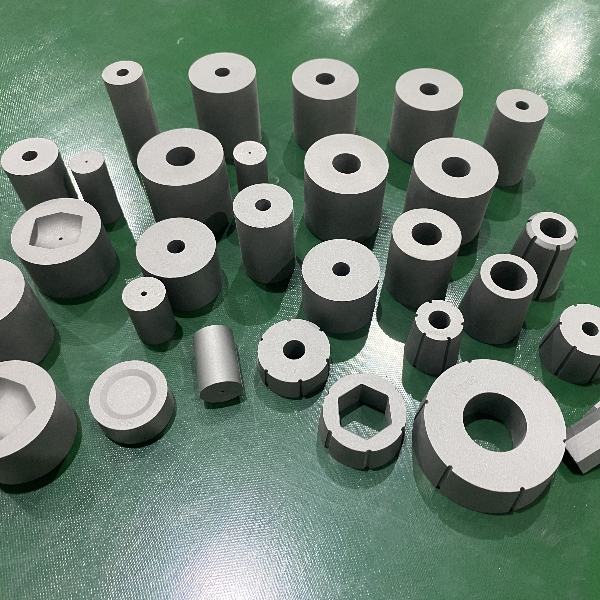

our tungsten carbide pallet compositions represent a breakthrough in materials science, delivering unparalleled strength, durability and performance in a wide range of applications. Whether in industrial settings or consumer products, this material sets new standards for engineering and design possibilities. Experience the difference our tungsten carbide composition can make on your next project and discover the endless possibilities it offers.

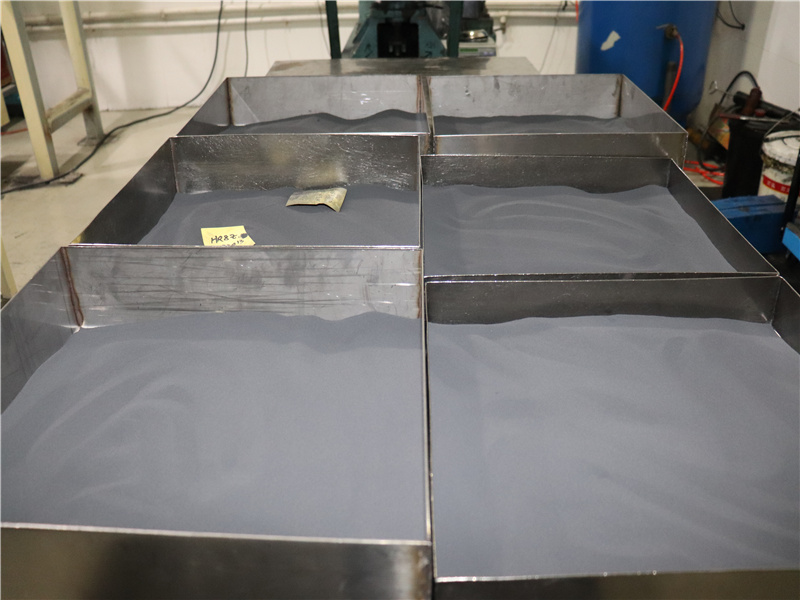

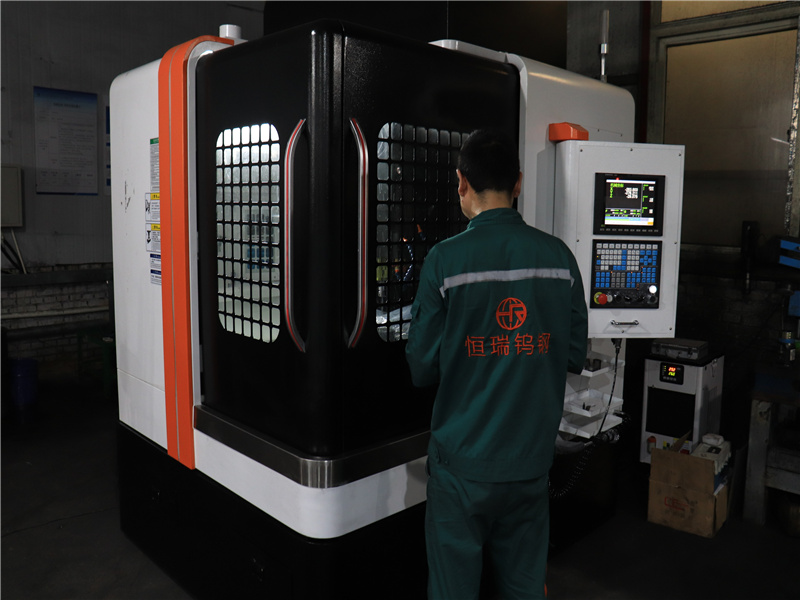

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

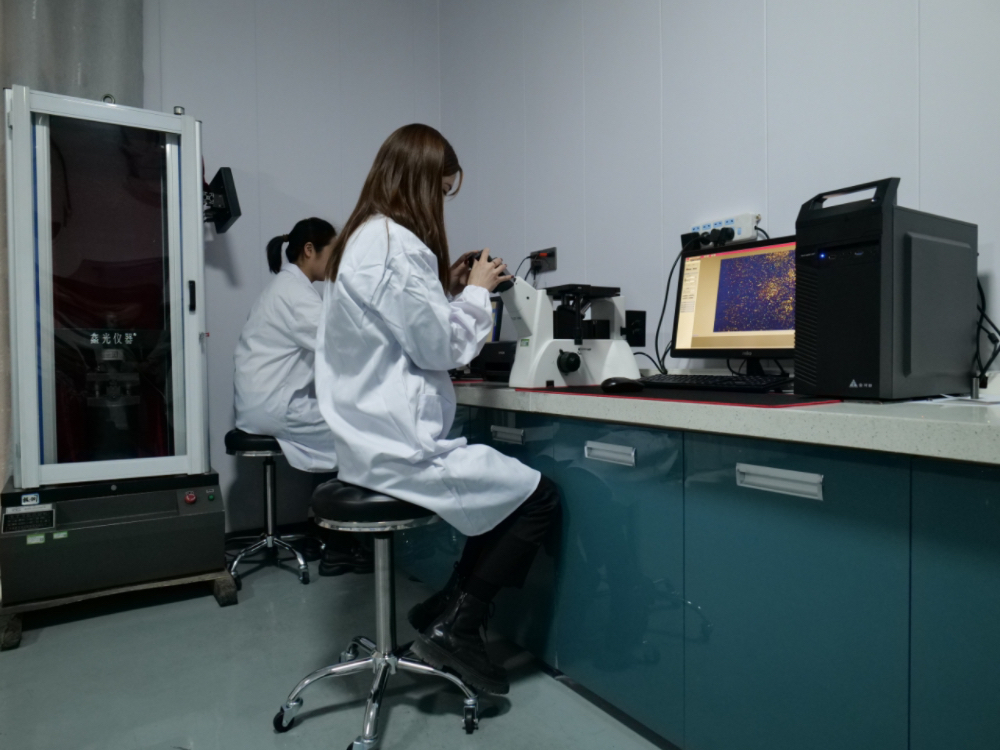

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Shipping express

Our company has in-depth cooperation with well-known express delivery companies. DHL UPS delivers according to your needs.

Are the hexagonal heads of the screws protruded?

A: Most of them are made of piers, because this can save materials. Depending on the tonnage of the pier forging machine and the bolt diameter, cold pier or hot pier technology can be used.

02

Are the bolts entirely die cast?

A:If the bolt material is an alloy or metal with a low melting point such as aluminum alloy, zinc alloy, copper alloy, etc., die casting can also be used. Steel ones are not made by die casting.

03

What's your delivery time for our orders?

A: The delivery is about 3day for standard productsand 25-30 days for OEM products.

04

After Services:

A: 1.Our sales team will respond to your question within 24 hours

(holidays excluded).2.Technical support will be available at any time.3.we can assure you of a 100% refund you the money for thequality problem.