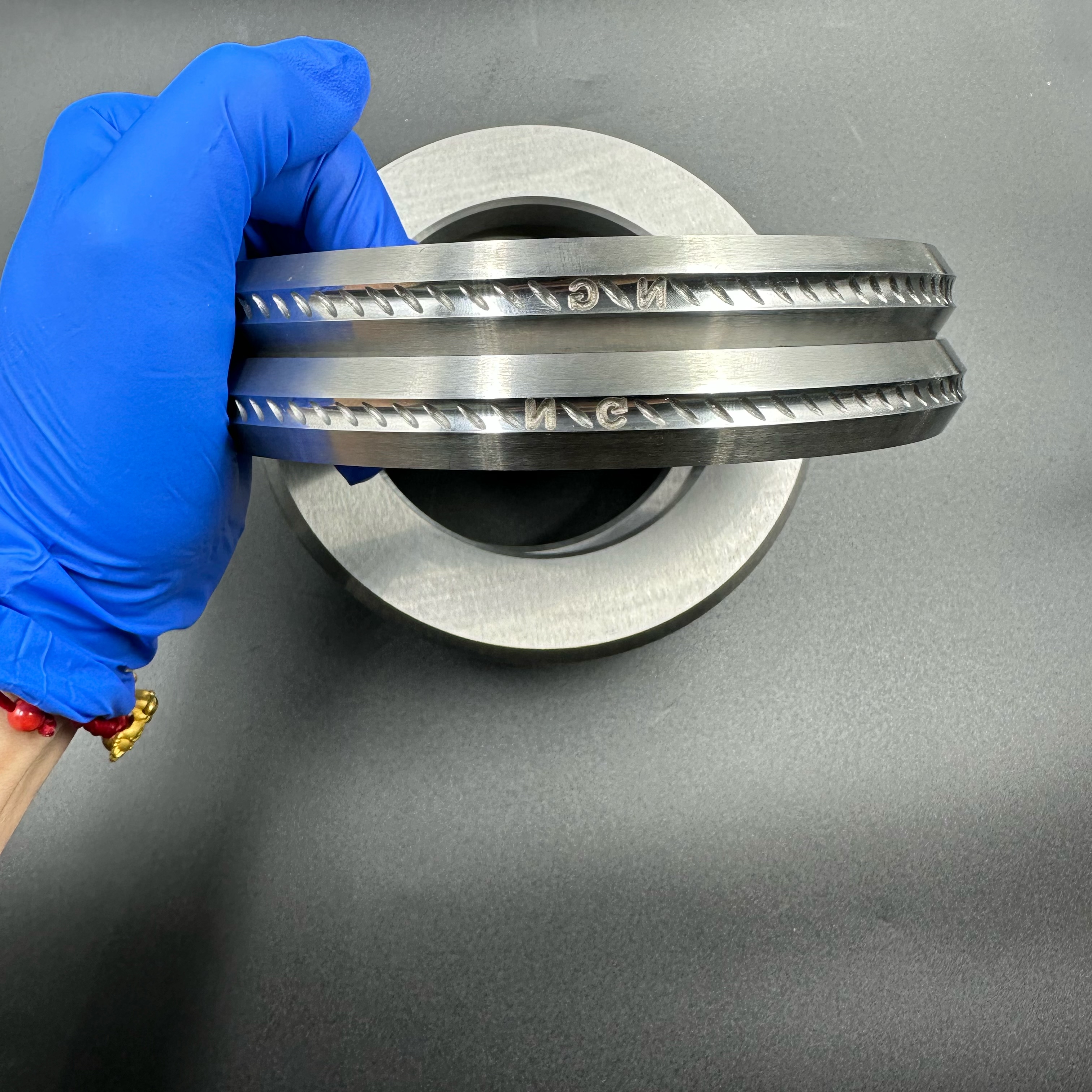

125X82X15mm RO2 Rt2 Tungsten Carbide Rolls for Malaysia Market

1. Chinese factory specialized in processing and production, ISO certification.

2. Multiple sizes and types available for OEM.

3. Made of 100% original high-quality materials

4. Professional production team, fast delivery

5. Free professional after-sales service and technical support

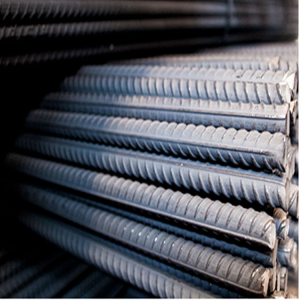

The benefits of using tungsten carbide cold rolls are numerous. They offer extended tool life, reduced downtime for roll changes, and improved surface finish on the rolled metal. Additionally, their high thermal conductivity helps dissipate heat during the rolling process, leading to better control of the metal’s properties.Tungsten carbide cold rolls are highly sought after in the industry due to their exceptional wear resistance and thermal conductivity. This allows for efficient and precise cold rolling of metal sheets and strips, resulting in high-quality finished products.

Tungsten carbide cold rolls are essential in the metal forming process, particularly in the production of steel and other metals. These rolls are made from a combination of tungsten and carbon, resulting in an incredibly hard and durable material that can withstand the extreme pressures and temperatures of cold rolling.

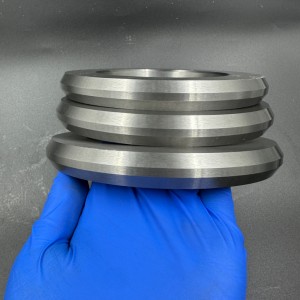

The manufacturing process of tungsten carbide cold rolls involves sintering the tungsten carbide powder at high temperatures, followed by precision grinding to achieve the desired shape and dimensions. The end result is a roll that is capable of withstanding the intense mechanical and thermal stresses of cold rolling operations.

Tungsten carbide cold rolls are highly sought after in the industry due to their exceptional wear resistance and thermal conductivity. This allows for efficient and precise cold rolling of metal sheets and strips, resulting in high-quality finished products.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. Good corrosion resistance.

2. High precision.

3. Ra0.2 surface roughness.

4. Made from 100% virgin raw material.

5. Produced go through in-process and final inspection.

6. Stable and continuous production ability.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

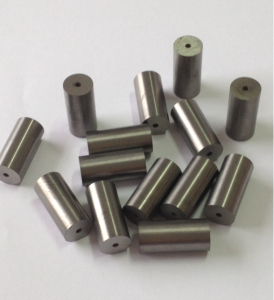

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.