15% – 25% Cobalt Grade Tungsten Carbide Pellets For Cold Heading Dies

1. Proffessional cemented carbide manufacturer over 17 years.

2. Located in HeBei, A well-known hub for the production of cemented carbide,We have easy access to a wealth of raw materials.

3. Annual production capacity over 400tons.

4. More than 10000 sets of exisiting non-standard molds,fast delivery!

5. Top R&D team and 12-member QC team that follows a five-point inspection routine,covering raw material,production processes, semi-finished products, finished products and packaged goods.

6. ISO9001:2008 Quality Management System.

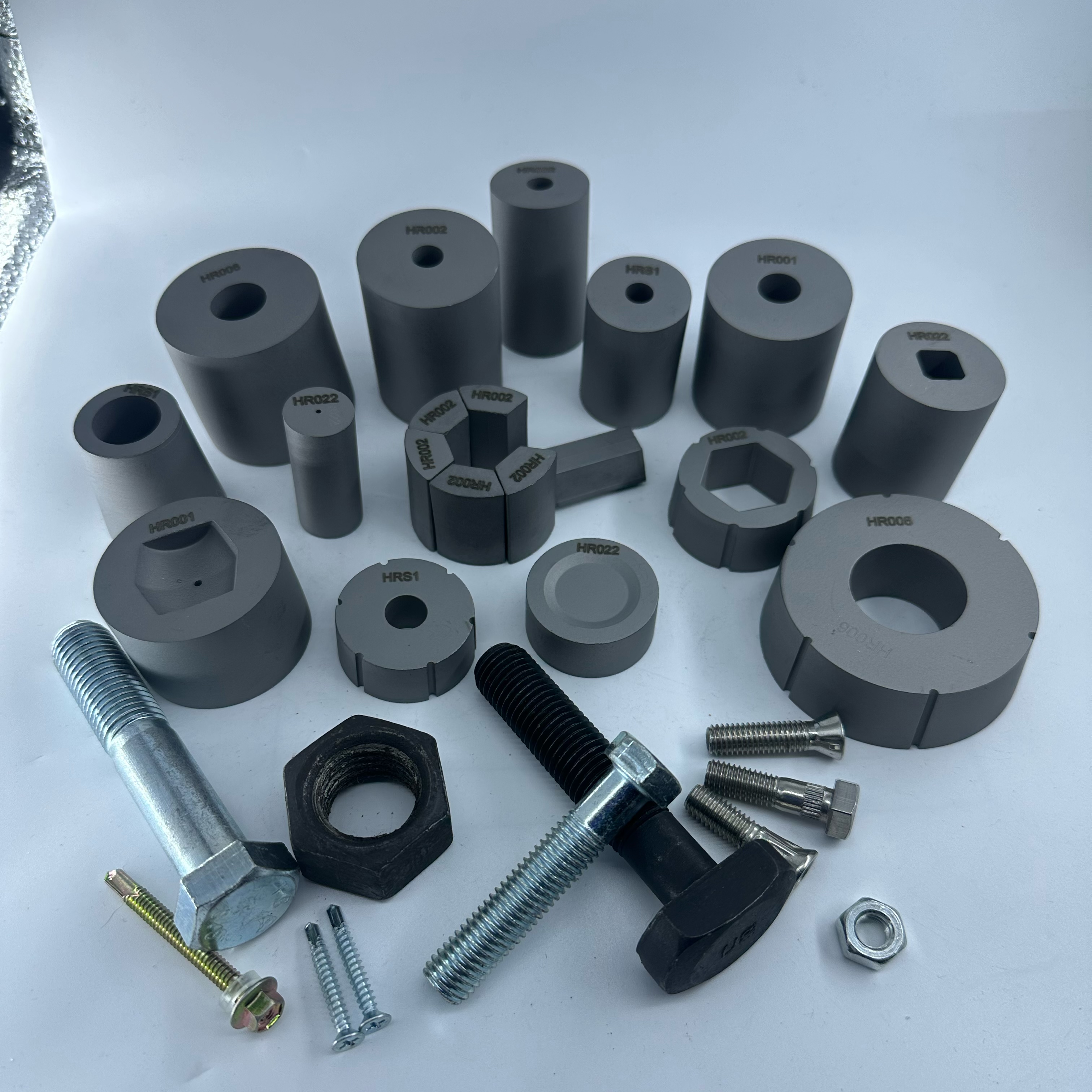

Tungsten Carbide Cold heading pellet that we offer is high on demand in the markets. Our heading pellets Pressed under controlled process with CIP, Heading pellet suits the set industrial standards and norms. Clients can avail heading pellet at highly competitive rates. Cold-forming tools like heading dies are designed to sustain high and repeated stress. Tungsten carbide makes the use of cold-forming technology possible for mass production of high-volume parts like screws, bolts, and rivets. Our grades make it possible for our heading dies to last a long time and deliver superior part accuracy.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

- Every production process has a special person to test to ensure quality

- Have professional engineers to check the quality

- All products are under strict quality system management based on ISO9001:2008

1. Use 100% tungsten carbide raw material.

2. Stable chemical properties

3. Excellent performance and good wear/corrosion resistance

4. HIP sintering,good compactness

5. Blanks,high machining accuracy/precision

6. OEM customized sizes available

7. Factory’s offer

8. Strict products quality inspection

1. Good corrosion resistance.

2. High precision.

3. Ra0.2 surface roughness.

4. Made from 100% virgin raw material.

5. High Hardness: 6%-10% Co grade, fine to medium grain size

6. High Strength: 15%-25% Co grade, medium to coarse grain size

7. Good Wear Resistance: Fine to Ultrafine grain size, hardness can reach 92-93HRA

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.