YG15 YGH30 Tungsten Carbide Ring Roller for Wire Rod Mills

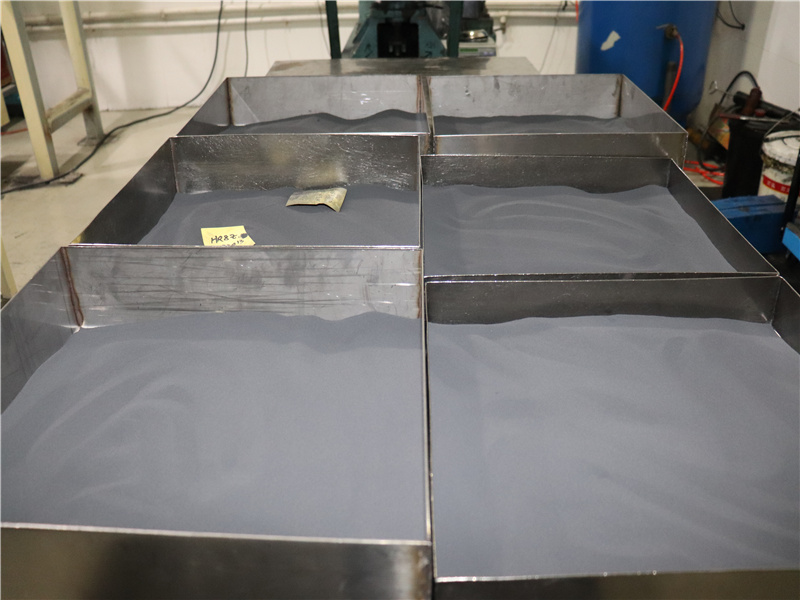

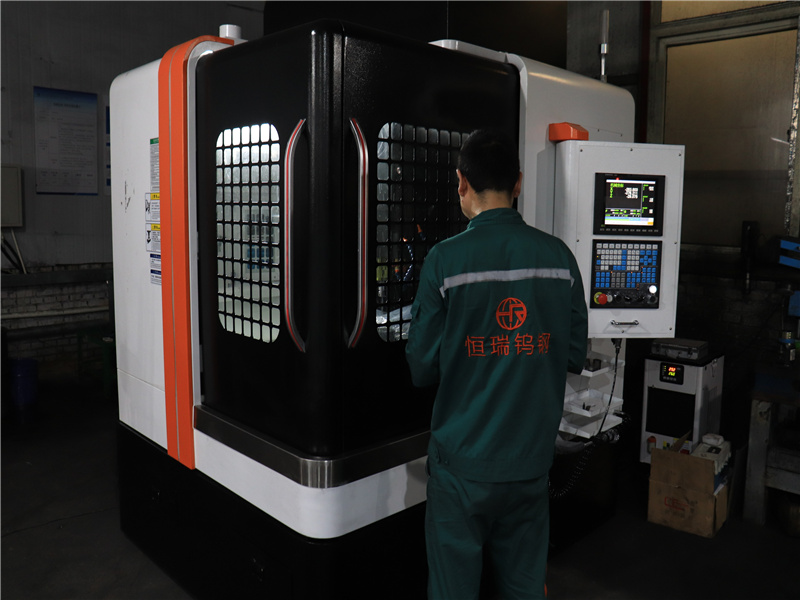

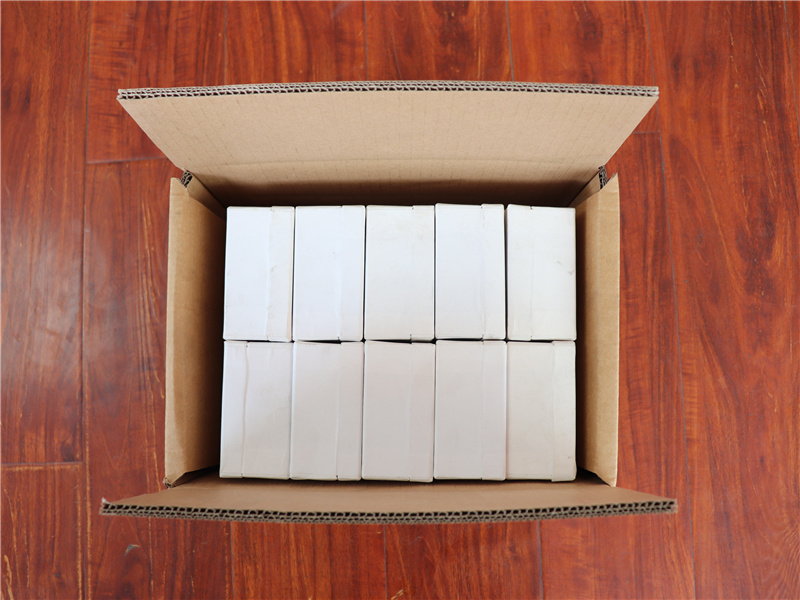

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Tungsten carbide roll is a high-strength, high-hardness roll, which is widely used in the rolling production of steel, non-ferrous metals and other industries. Specific applications include the following aspects: 1. Steel industry: Cemented carbide rolls are widely used in hot rolling, cold rolling, medium plate rolling and other links in steel production. By using cemented carbide rolls, the efficiency and quality of rolling production can be improved, and the number of roll replacements and production costs can be reduced. 2. Non-ferrous metal industry: Carbide rolls are also widely used in non-ferrous metal production. For example, the use of cemented carbide rolls in the rolling process of copper plates and aluminum plates can effectively reduce surface defects and improve the surface quality of plates. 3. Other industries: Carbide rolls can also be used in construction materials, packaging materials, machinery manufacturing, precision machinery and other fields, for rolling, pressing, friction, grinding and other production. In general, cemented carbide rolls have a wide range of applications and are indispensable and important parts in many production processes.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

| Grade | Chemical

Composition |

Physical&Mechanical properties | |||

|

WC |

Co | Density

g/cm3 |

Hardness

HRA≥ |

TRS

≥Mpa |

|

| YGH30 | 85% | 15% | 13.8-14.2 | 83.5 | 2520 |

| YG15 | 85% | 15% | 13.9-14.2 | 86.5 | 2220 |

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.

Q1: Why did you choose us?

A1: We are the factory, we offer our clients are all wholesale price and best quality.

Q2: Do you provide free samples?

A2: Yes, we welcome all clients to get free samples for testing under the condition of freight paid by customer.

Q3: What is your minimum order requirement?

A3: We hope you clear your quantity, if you do not have, we will indicate the MOQ for each item in the quotation sheet. We welcomethe sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

Q4: What is the delivery time of your products?

A4: It depends on the inventory availability. If items needed are in stock, the delivery time would be within 7 work days, but if not thedelivery time would be around 7-30 work days.

Q5: What kinds of production do you supply?

A5: We can produce both standard production and special production. Based on your request, drawings