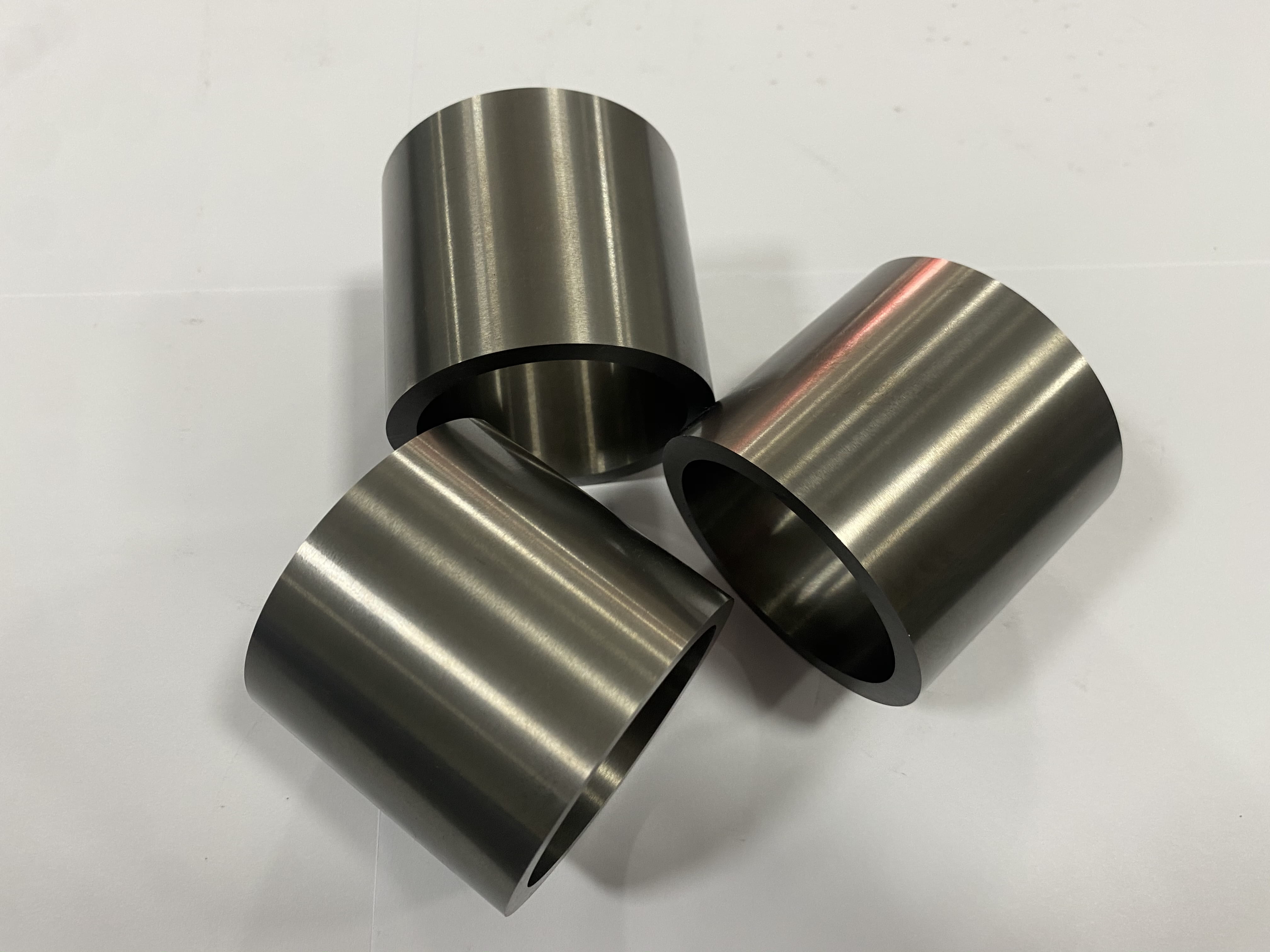

Factory wholesale Endurance Tungsten Carbide Bushings

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Factory wholesale Tungsten Carbide Diamond Split Wire Drawing Dies, We wholeheartedly welcome shoppers all around the globe come to go to our manufacturing facility and have a win-win cooperation with us!

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for China Carbide bushing tungsten carbide bushing and bushing Sleeve , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Video

Product Description

Tungsten carbide bushings, as wear-resistant parts in petroleum machinery wells, have high hardness, good wear resistance and high finish, and have been used more and more widely in modern society to meet the needs of daily use and special performance. Some companies use the spray welding process to improve the durability and service life of cemented carbide bushings.

Tungsten carbide wire drawing dies have the following features which ensure the high durability:

1. Strong power resistance

2. Excellent wear resistance

3. Sufficient thermal stability

4. Excellent process ability

Matters needing attention and maintenance of Tungsten carbide bushing

1,The main material carbide has a series of excellent properties such as high hardness, wear resistance, better strength and toughness, heat resistance, corrosion resistance, etc. In particular, its high hardness and wear resistance remain largely unchanged even at a temperature of 500°C and still have a high hardness at 1000°C.

2.Cemented carbide bushings, also known as tungsten bushings, are an alloy material made from hard compounds of refractory metals and bonded metals through a powder metallurgical process. Tungsten steel bushings are mainly used in stamping applications and are wear and impact resistant.

3.Adopting advanced forming technology, it can produce various complex shapes of carbide products.

Small deformation and very high precision.

No machining is required or only a small amount of machining is needed.

4.After spray welding the hardness of the carbide bushings can reach HRC60, better wear resistance, can meet the requirements of the petroleum machinery industry, but after spray welding the carbide bushings need to be turned in order to ensure the size requirements and accuracy requirements of the drawings.

5. Carbide bushings in the stretching, mainly some copper, stainless steel parts of the stretching, due to the use of too high a frequency, easy to heat, resulting in wear bushings, so that the punch needle run, the size of the product error, and the appearance of the product is not good.

Summary

The tungsten carbide bushing are widely used for drawing in various industries. It has high hardness, excellent thermal stability, high durability, and long service life and is one of the best mold materials.

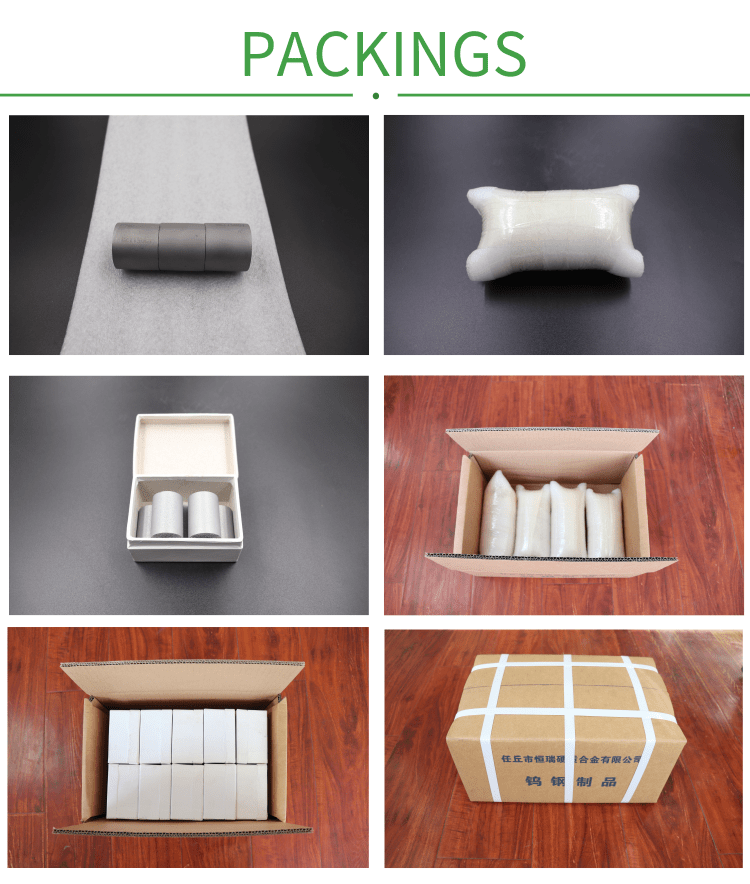

Package

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Factory wholesale Tungsten Carbide Diamond Split Wire Drawing Dies, We wholeheartedly welcome shoppers all around the globe come to go to our manufacturing facility and have a win-win cooperation with us!

Factory wholesale China Carbide Split Dies and Wire Drawing Dies, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.