Best Quality Tungsten Carbide Cold Heading Pallets heading pallet

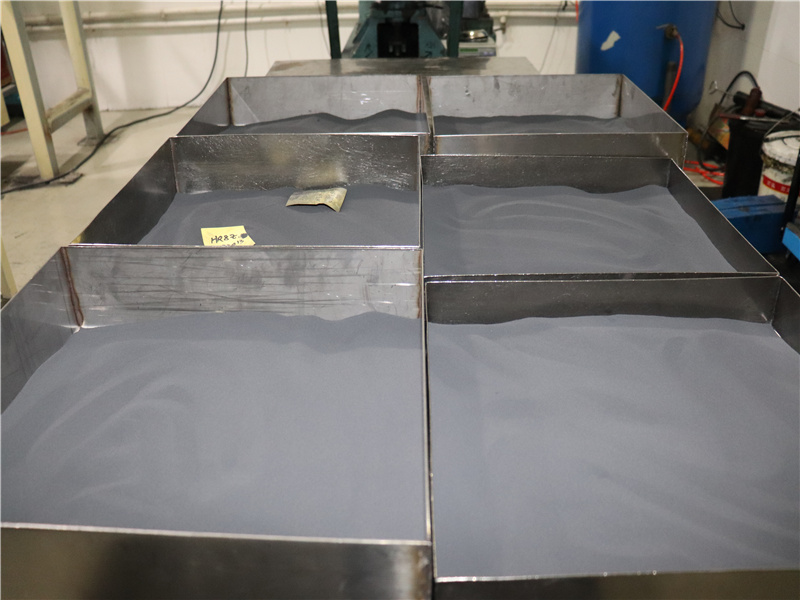

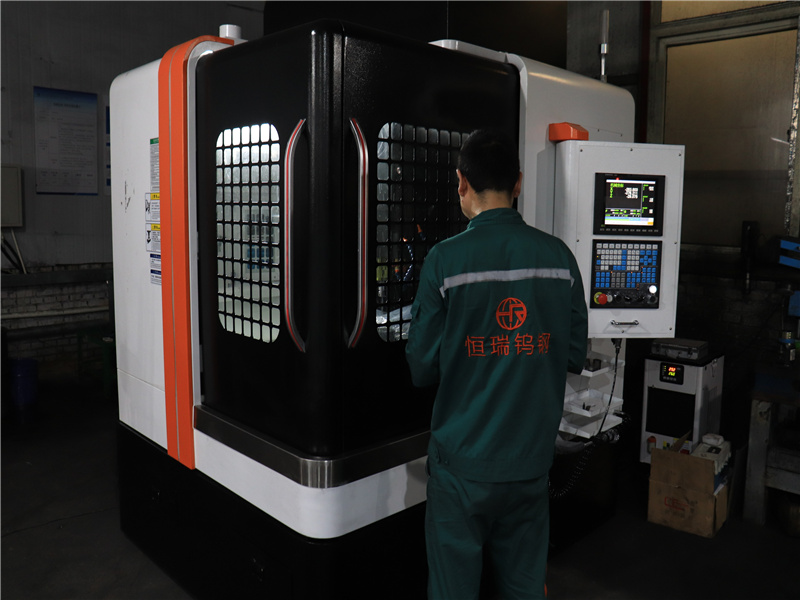

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

The tungsten carbide cold pier mould has a number of advantages over other types of piercers:

1. High wear resistance: Tungsten carbide is a very hard and wear-resistant material, making it ideal for use in high-pressure and high-speed rolling operations. The cold pier mould can withstand the high stresses and pressures encountered during the piercing process, resulting in reduced wear and longer service life.

2. Improved dimensional accuracy: The high wear resistance of tungsten carbide rollers ensures that the cold pier mould maintains its shape and size, resulting in improved dimensional accuracy of the final product.

3. Enhanced surface finish: The use of tungsten carbide rollers in the piercing process results in a smoother surface finish of the tube or pipe, reducing surface defects and improving product quality. 4. Reduced maintenance requirements: The superior wear resistance of tungsten carbide enhances the life of the cold pier mould, resulting in reduced maintenance and replacement costs.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.