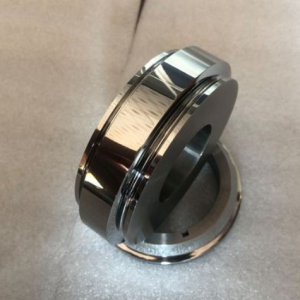

YG15 High Hardness Tungsten Carbide 3D Roller

1、What is the Warranty for the products?

We use the best and suitable material to fit your request and market,We own high precision grading machine to control geometry dimensions and guarantee the lifetime of our products,Which can staisfy every working condition.If any quality problems on our side occurred in this period,We will find a best way to reduce your loss,You satisfaction is our first purpose!

2、Do you provide free samples?

Yes,We welcome all clients to get free samples for testing under the condition of freight paid by customer.

3、What is your minimum order requirement?

We hope you clear your quantity .If you do not have,We will indicate the MOQ for each item in the quotation sheet.We welcome the samples and trial order.if the quantity of single item can't reach the MOQ,The price should be sample price.

4、What is the delivery time of your products?

It depends on the inventory availability.If items needed are in stock.The delivery time would be within 7 work days,But if not be the delivery time would be around 7-30days.

5、What kinds of production do you supply?

We can produce both standard production and special production.Based on your request,drawings and samples.

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Before mass production, we need to do a trial pressing and sintering , and we check the appearances and the size, density and hardness of samples with micrometer, Metallurgical microscope, densitometer etc. to ensure that the requirements of the drawings can be met before batch production; All the products must be inspected strictly by our QC.

1. Good corrosion resistance.

2. High precision.

3. Ra0.2 surface roughness.

4. Made from 100% virgin raw material.

5. Produced go through in-process and final inspection.

6. Stable and continuous production ability.

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment, while, If there is soecific requests on delivery time. We can make change according to clients’ request, so a shorter delivery time is absolutely available.

Usually 30% T/T in advance, balance 70% against B/L copy. Also could change according to clients’ request.

We manufacture components in different shapes and sizes to match our customers’ requirements exactly, whether they need blocks or sheets, cylinders, bearings, tips or teeth.

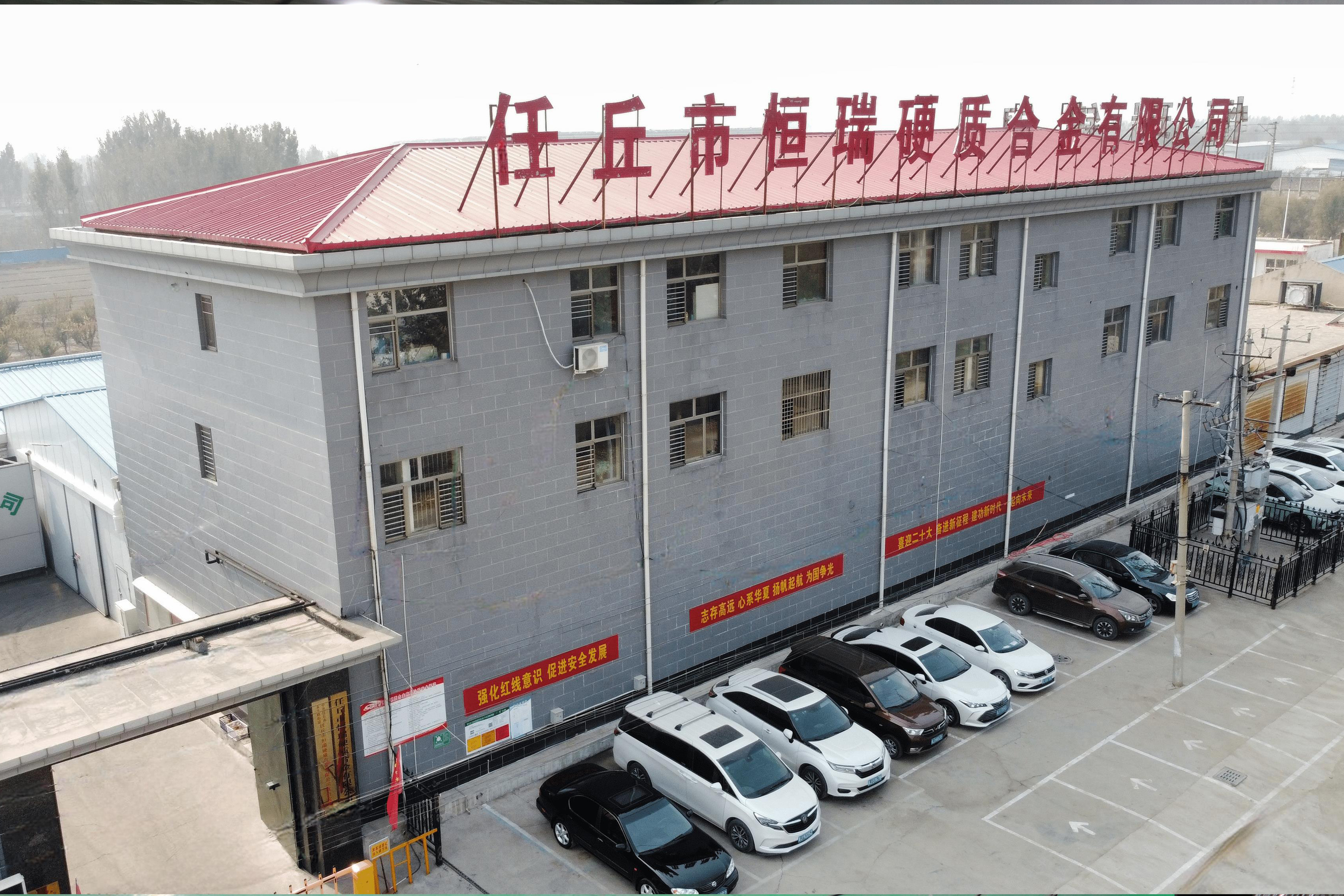

Q1: Why did you choose us?

A1: We are the factory, we offer our clients are all wholesale price and best quality.

Q2: Do you provide free samples?

A2: Yes, we welcome all clients to get free samples for testing under the condition of freight paid by customer.

Q3: What is your minimum order requirement?

A3: We hope you clear your quantity, if you do not have, we will indicate the MOQ for each item in the quotation sheet. We welcomethe sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

Q4: What is the delivery time of your products?

A4: It depends on the inventory availability. If items needed are in stock, the delivery time would be within 7 work days, but if not thedelivery time would be around 7-30 work days.

Q5: What kinds of production do you supply?

A5: We can produce both standard production and special production. Based on your request, drawings