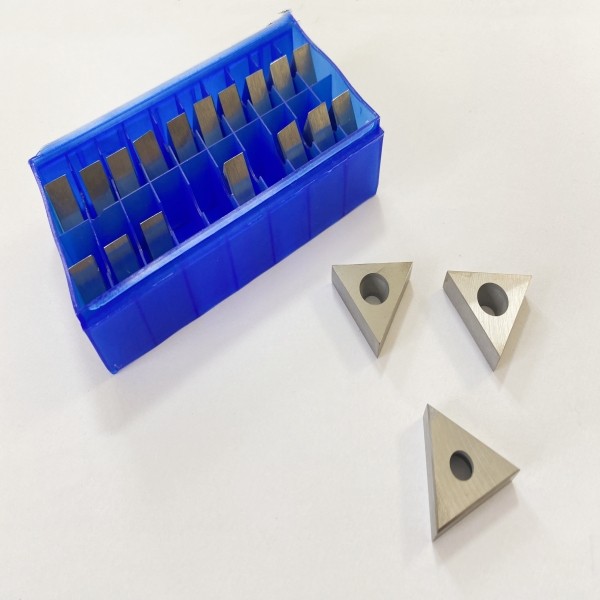

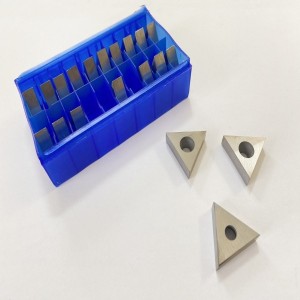

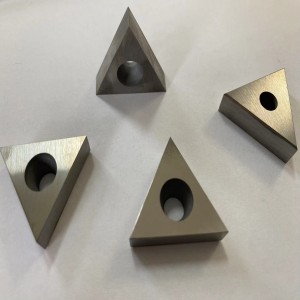

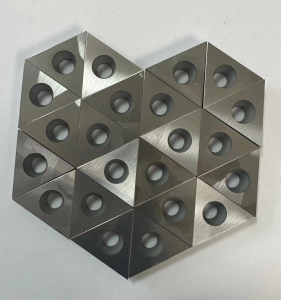

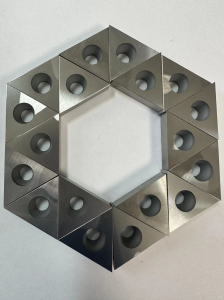

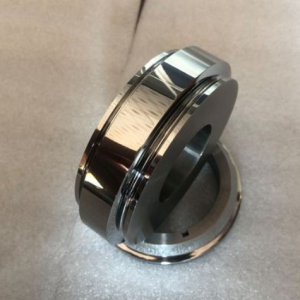

Tungsten Carbide Inserts with high hardness Good wear resistance

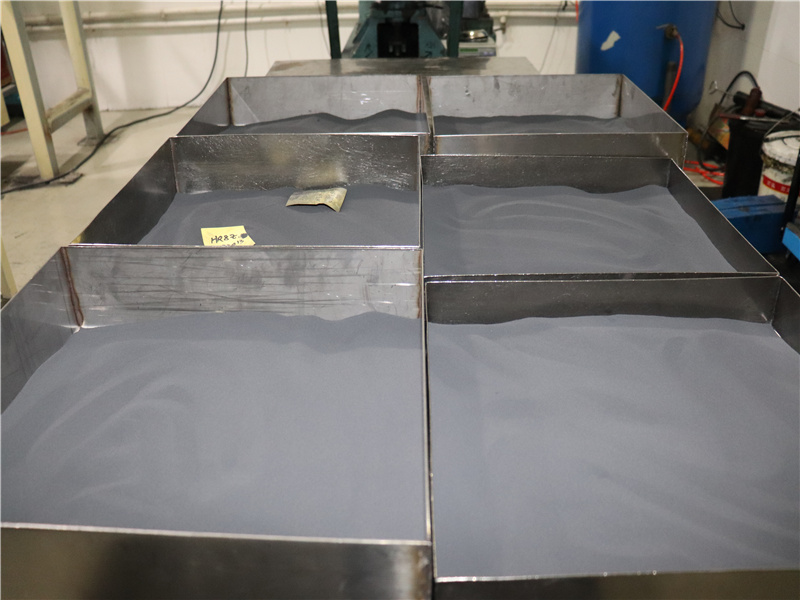

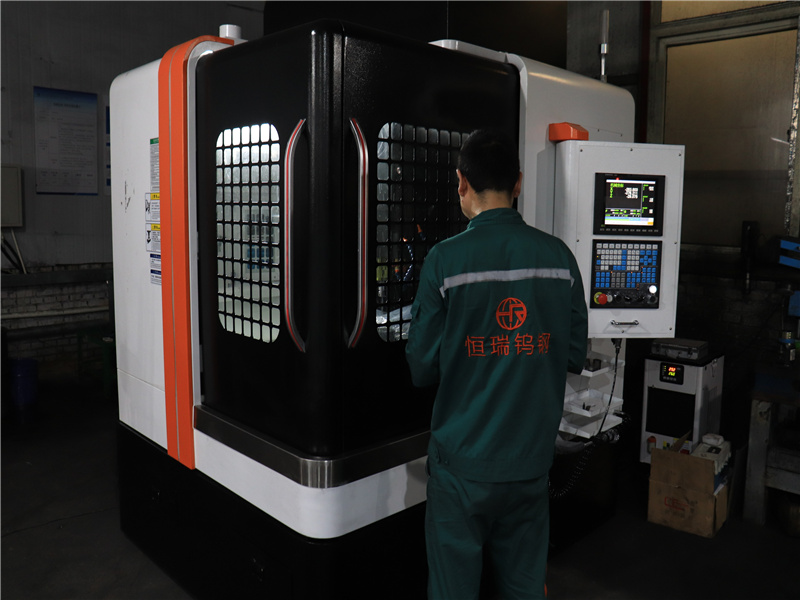

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

The benefits of using cemented carbide inserts as wear-resistant parts are as follows: 1. Super wear resistance: Carbide inserts have very high hardness and wear resistance, which can effectively resist wear and abrasion of materials and prolong tool life. 2. High-speed cutting ability: Due to the high hardness of the cemented carbide insert, it can effectively maintain the shape and hardness of the tool during high-speed cutting, making the cutting speed higher. 3. Good corrosion resistance: Carbide inserts have good corrosion resistance and can work in some special environments, such as precise cutting in corrosive liquids and oxidizing media. 4. Very precise: Carbide inserts have high processing precision and high dimensional precision, and can process high-precision products that meet the requirements. 5. Good repetitive processing performance: the stability of the cemented carbide blade is high, and the consistency and precision of the product can be guaranteed even if the same product is processed repeatedly. In summary, cemented carbide inserts have the advantages of high wear resistance, high precision, high-speed cutting and good corrosion resistance, and are good wear-resistant materials.

Normally use the grade YG6F YG6X YG8 YG10 YG11 YG30 ETC

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

We will delivery the mass produced cargo within 30days after the down payment,while,If there is soecific requests on delivery time.We can make change according to clients’ request,so a shorter delivery time is absolutely available.