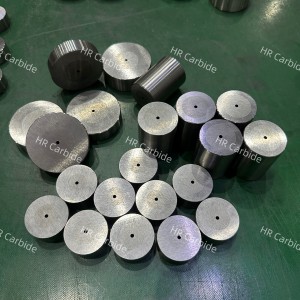

CT95 HR006 VA95 hardness HRA82 Tungsten carbide cold heading dies TC pellets for fastener mold

Furthermore, tungsten carbide exhibits high compressive strength, making it capable of withstanding the extreme pressures involved in hot forging operations. This results in minimal deformation or deflection of the dies and molds, leading to consistent part dimensions and surface finish.

Another advantage of choosing tungsten carbide for hot forging dies and molds is its resistance to corrosion and chemical attack. This makes tungsten carbide tools suitable for use in a wide range of forging applications, including those involving reactive or abrasive materials.

When it comes to selecting a supplier for tungsten carbide hot forging dies and molds, it is essential to choose a reputable and experienced manufacturer. Our company specializes in the production of high-quality tungsten carbide tools for hot forging applications. With our expertise and commitment to quality, we can provide you with reliable and durable tungsten carbide hot forging dies and molds that meet your specific requirements.

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

1. Why choose us?

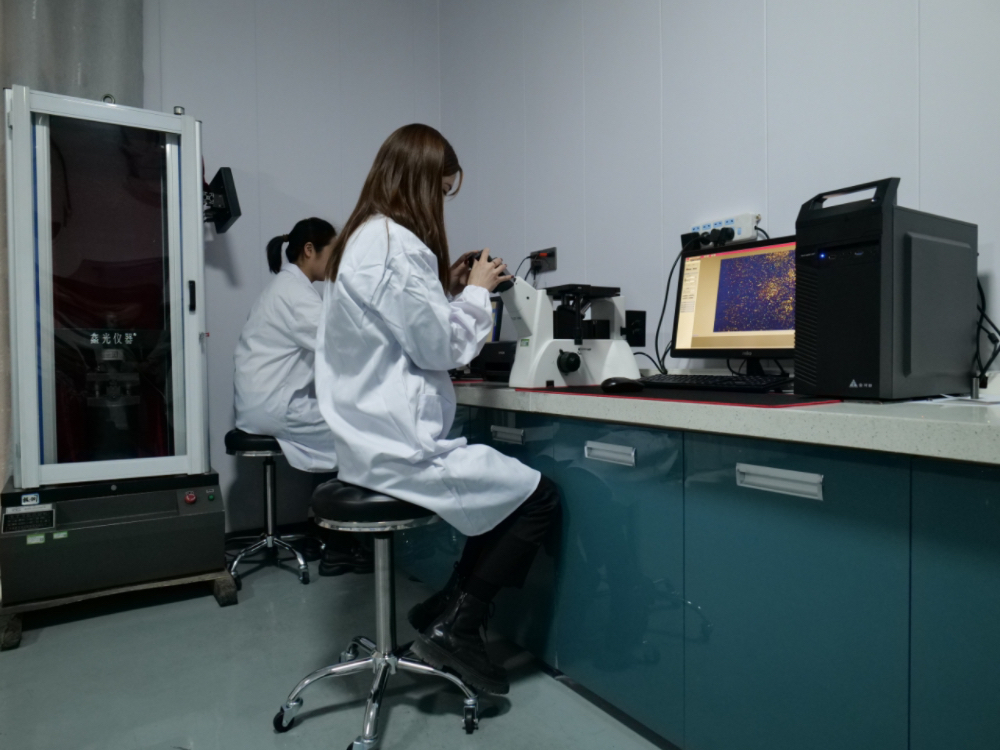

We are a manufacturer with 19 years of production experience, focusing on the production of tungsten carbide cold heading molds. We have professional engineers, and we have our own independently developed grades to cope with different markets.

2. Does your price have any advantage?

We have different grades of tungsten carbide and different price levels according to your different needs. From tungsten carbide blank production to mold finishing, we have our own production workshop and can give you the ex-factory price.

3. Can you accept trial orders?

Yes, we accept trial orders and there is no minimum order quantity. We can also provide free samples. Please contact our business manager for details.