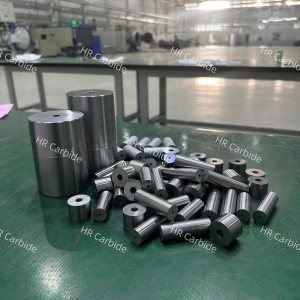

China manufacturer supply cemented carbide cold heading dies with surface grinding

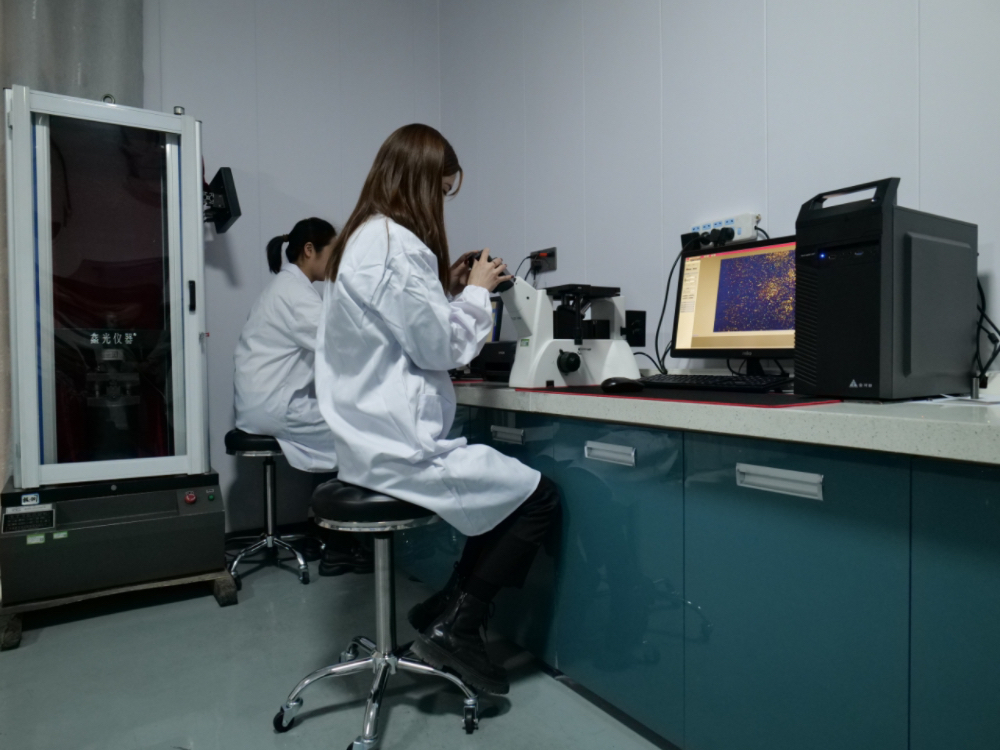

Our commitment to quality and innovation is reflected in the rigorous quality control measures implemented throughout the manufacturing process. Each cold heading die is thoroughly inspected to guarantee its dimensional accuracy, surface finish, and overall performance, providing our customers with the confidence that they are investing in a reliable and high-performing product.

At the heart of our cold heading dies is the use of high-quality cemented carbide, renowned for its superior hardness, wear resistance, and toughness. This material is carefully selected to withstand the extreme pressures and abrasive forces encountered during the cold heading process, resulting in dies that maintain their shape and integrity over prolonged use.

1.Original manufacture for 19 years

2.Mature Processing department for finished mold

3.Experienced exportation team for direct sale

All together gives you Guaranteed quality Based on competitive price at High Efficiency Delivery

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

- What is tungsten carbide cold forging die?

Tungsten carbide cold forging die is a tool used in the cold forging process to shape metal parts at room temperature. It is made of tungsten carbide, a hard and durable material that can withstand the high pressure and wear associated with cold forging. - What are the advantages of using tungsten carbide cold forging dies?

Tungsten carbide cold forging dies offer several advantages, including high wear resistance, excellent dimensional stability, and the ability to maintain tight tolerances during the forging process. They also have a longer lifespan compared to traditional steel dies. - What types of metal can be cold forged using tungsten carbide dies?

Tungsten carbide cold forging dies are suitable for cold forging a wide range of metals, including steel, aluminum, copper, and alloys. They can be used to produce various components such as automotive parts, fasteners, and hardware. - How are tungsten carbide cold forging dies manufactured?

Tungsten carbide cold forging dies are typically manufactured through a process called powder metallurgy, where tungsten carbide powder is compacted into the desired shape and then sintered at high temperatures to form a solid, dense die. - How can the lifespan of tungsten carbide cold forging dies be extended?

To extend the lifespan of tungsten carbide cold forging dies, it is important to properly maintain and lubricate the dies during the forging process. Additionally, using the correct operating parameters and avoiding excessive impact or overloading can help prolong the life of the dies. Regular inspection and maintenance can also help identify any wear or damage early on.