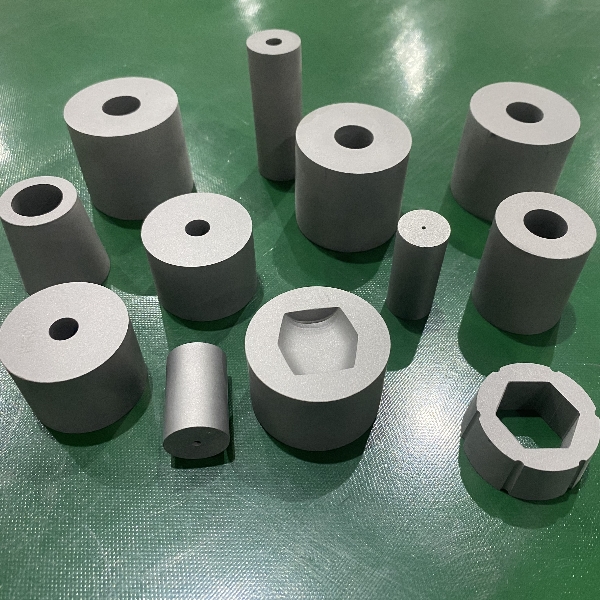

Tungsten carbide HR006 coarse particles and high impact toughness

Cold heading and hot heading are two different metal forming processes. Their main differences lie in the processing temperature, plastic deformation and thermal deformation. 1

Cold heading is a low-temperature processing technology that is usually performed at room temperature and does not cause thermal deformation, so it can maintain high accuracy during the processing. During the cold heading process, the workpiece will undergo significant plastic deformation, but the thermal deformation is very small, which causes the formation of fine pits on the surface of the workpiece, thus improving the strength, rigidity and linear stability of the workpiece. Cold heading is suitable for processing thin plates, castings, bearing sleeves and other parts. It has high processing efficiency and can use multi-process and multi-station forming.

Hot heading is a high-temperature processing technology that achieves plastic deformation and thermal deformation under low pressure and high temperature, which can greatly improve the surface roughness of the workpiece, increase the stiffness of the workpiece, and reduce plastic deformation. The temperature range of hot heading is relatively high, and the amount of plastic deformation is reduced, but it will produce a large amount of thermal deformation and form larger pits. Hot heading is more suitable for processing important parts, such as bolts, etc., because it can accurately control the size, depth and shape of the concave cup and has good support effect.

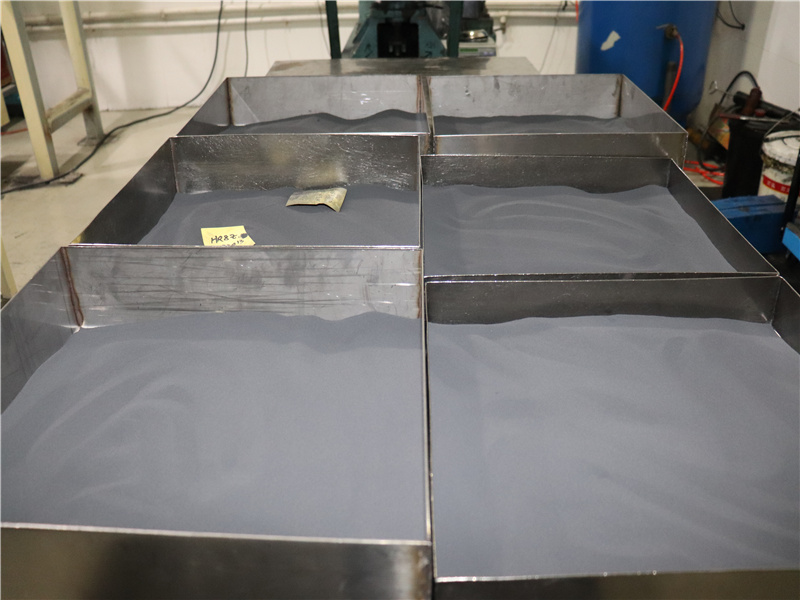

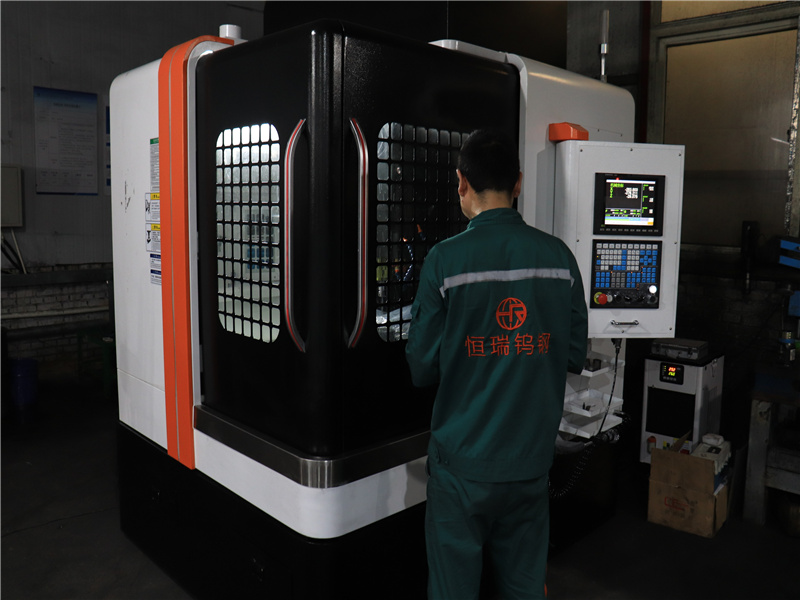

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

1. We will try our best to reply our customers’request within 24hours.

2. We will maintain effective and efficient communications with our customers.

3. We provide first-class quality control and after-sale services.

Shipping express

Our company has in-depth cooperation with well-known express delivery companies. DHL UPS delivers according to your needs.

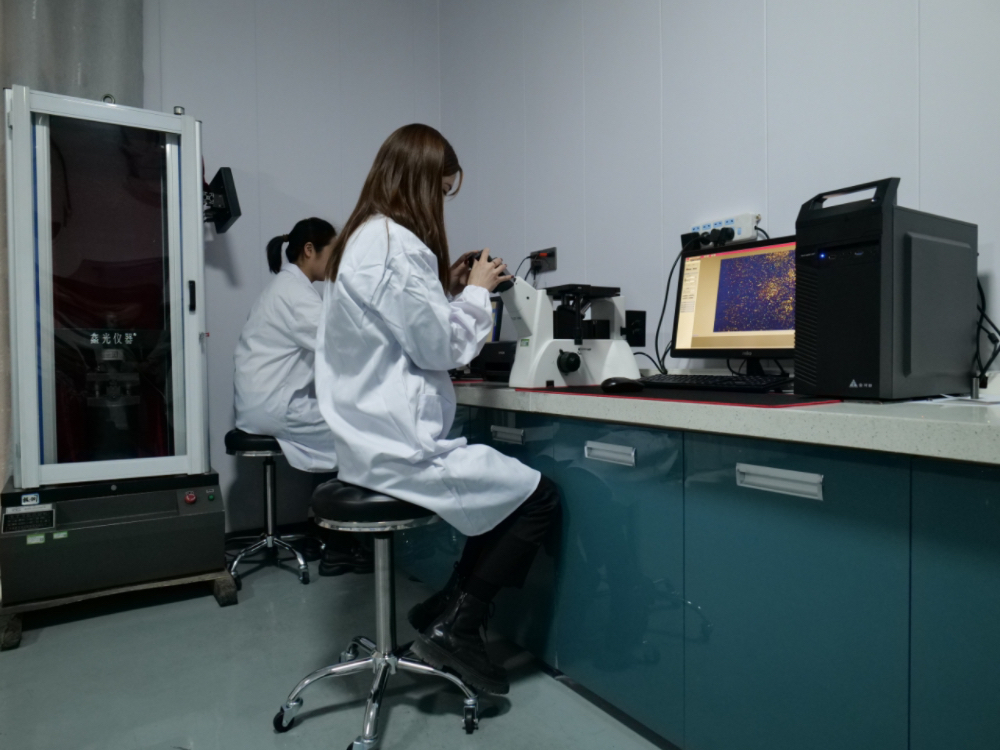

Do you have your own laboratory?

A: Yes, we have a laboratory that specializes in testing the composition of tungsten carbide

02

Do you have the inspection procedures?

A:Yes, we will conduct appearance and quality inspection on each product before shipment

03

What's your delivery time for our orders?

A: The delivery is about 3day for standard productsand 25-30 days for OEM products.

04

After Services:

A: 1.Our sales team will respond to your question within 24 hours

(holidays excluded).2.Technical support will be available at any time.3.we can assure you of a 100% refund you the money for thequality problem.