CT95 VA95 HR006 GT55 Tungsten Carbide Cold Forging Dies Cold Heading Carbide for Fasteners

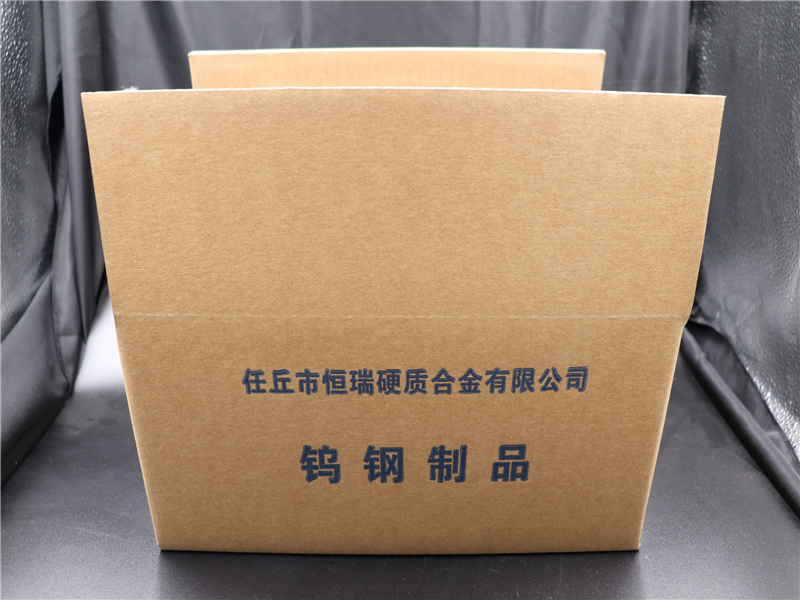

At [Renqiu Hengrui Cemented Carbide Co.,Ltd], we are committed to providing our customers with the highest quality tools and equipment. Our Tungsten Carbide Cold Forging Dies are a testament to this commitment, offering unmatched durability, precision, and reliability for cold forging applications.

Our Tungsten Carbide Cold Forging Dies are manufactured using advanced techniques and materials to ensure exceptional durability and performance. Tungsten carbide, known for its hardness and resistance to wear, is the primary material used in the construction of these dies. This results in a product that can withstand the repetitive impact and high stress conditions of cold forging, providing a longer service life and reducing the need for frequent replacements.

The precision engineering of our cold forging dies ensures consistent and accurate shaping of metal components, leading to high-quality finished products. Whether it's forming intricate shapes or creating complex geometries, our dies deliver the precision and reliability needed to meet the strict tolerances of modern manufacturing standards.

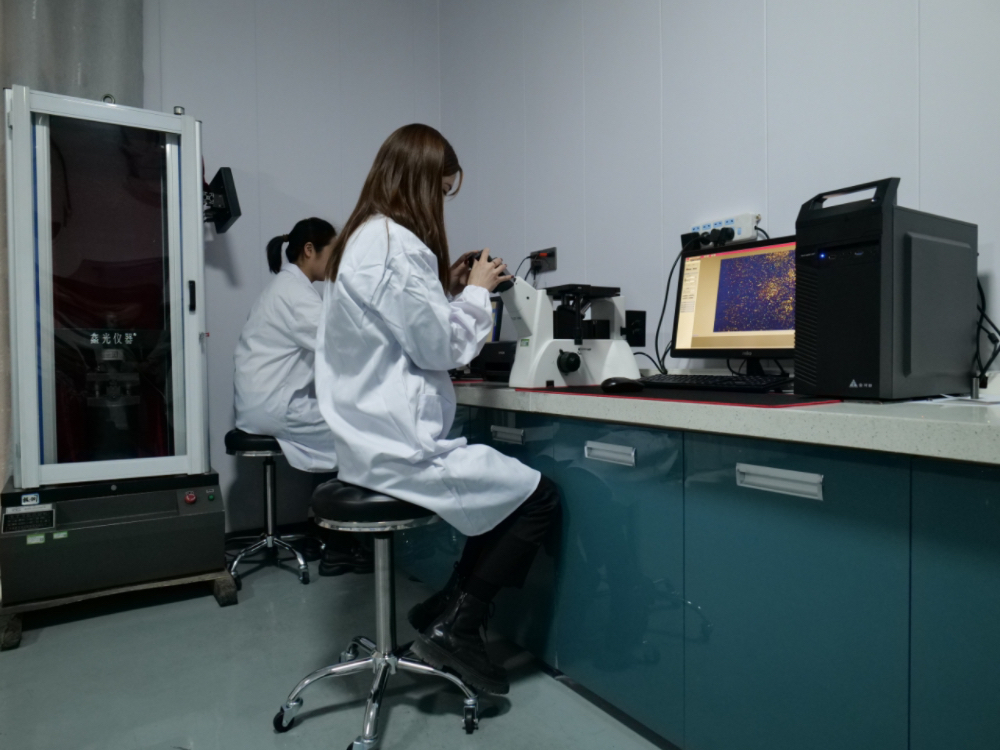

1.Original manufacture for 19 years

2.Mature Processing department for finished mold

3.Experienced exportation team for direct sale

All together gives you Guaranteed quality Based on competitive price at High Efficiency Delivery

We can send international express such as DHL, FedEx, UPS, SF Express, etc. We can also choose lower-cost shipping methods such as sea transportation and air transportation.

- What is tungsten carbide cold forging die?

Tungsten carbide cold forging die is a tool used in the cold forging process to shape metal parts at room temperature. It is made of tungsten carbide, a hard and durable material that can withstand the high pressure and wear associated with cold forging. - What are the advantages of using tungsten carbide cold forging dies?

Tungsten carbide cold forging dies offer several advantages, including high wear resistance, excellent dimensional stability, and the ability to maintain tight tolerances during the forging process. They also have a longer lifespan compared to traditional steel dies. - What types of metal can be cold forged using tungsten carbide dies?

Tungsten carbide cold forging dies are suitable for cold forging a wide range of metals, including steel, aluminum, copper, and alloys. They can be used to produce various components such as automotive parts, fasteners, and hardware. - How are tungsten carbide cold forging dies manufactured?

Tungsten carbide cold forging dies are typically manufactured through a process called powder metallurgy, where tungsten carbide powder is compacted into the desired shape and then sintered at high temperatures to form a solid, dense die. - How can the lifespan of tungsten carbide cold forging dies be extended?

To extend the lifespan of tungsten carbide cold forging dies, it is important to properly maintain and lubricate the dies during the forging process. Additionally, using the correct operating parameters and avoiding excessive impact or overloading can help prolong the life of the dies. Regular inspection and maintenance can also help identify any wear or damage early on.