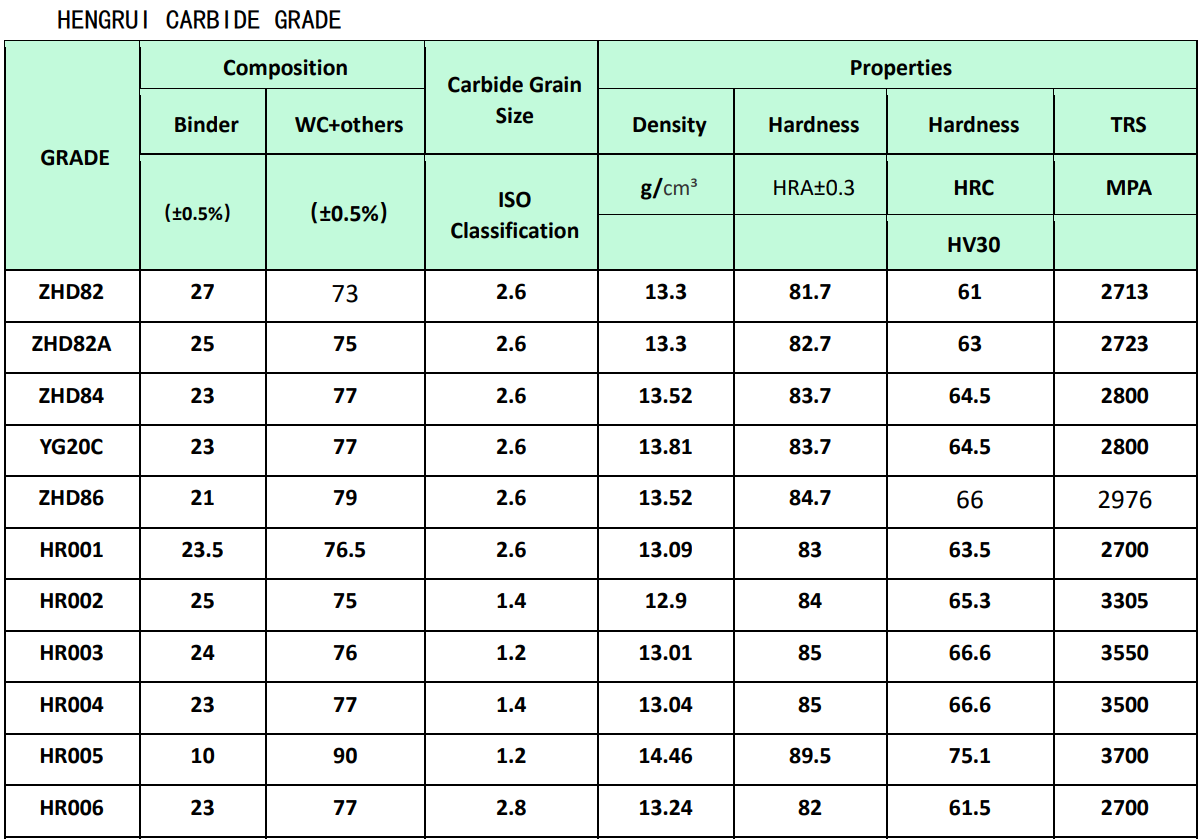

HR006 VA95 HR carbide High cobalt content Coarse grain size

The cold heading die bears the heavy pressing load, and its female die surface bears high-pressure stress so that the die core material is required to have high strength, toughness and wear resistance, tungsten carbide with high cobalt content(Most grades applied to the heading die core contains cobalt more than 12%, some even reach up to 25%) can perfectly meet this requirement, so all better heading die with long service time use tungsten carbide as die core material, and the outer case of the die is made of hot working die steel (the hardness after heat treatment is about HRC 45).

Material Matching→Wet Ball Milling→Mixed WC and Cobalt Power→Pressing→HIP Sintering Furnaces→QC Detecting→Packing

Advantages:

1.The raw materials were choose strictly from the first step, the size of the WC is medium and course and the cobalt powder is imported one.

2.The advanced technology and machine will be used on low pressure sintering.

3.The HIP sintering will brings better density and strength, especially on working application is obvious.

4.special powder pressing technology with HIP sintering, reducing the porosity, improve the density and catachrestic.

5.we choose the suitable grade according to the exactly usage.

1. It has high hardness and strength to ensure that the mold is resistant to pressure, wear, deformation and adhesion during work;

2. It has high wear resistance to ensure that the shape and size tolerances of the mold change within a certain range during long-term operation and will not fail due to excessive wear;

3. Have sufficient toughness to prevent the mold from brittle fracture under impact load;

4. The heat treatment deformation is small to ensure that the mold will not be scrapped due to excessive deformation during heat treatment;

5. It has high thermal hardness to ensure that the mold will not soften due to temperature rise during high-speed stamping or heavy-load stamping processes.

1. Contact us, our business manager is online 24 hours a day.

2. If we do not respond to your message in time, please send your drawing request to our email.

3. We will give you a quotation within 24 hours after receiving your order.

Delivery takes 3~10 days after receiving deposit